Thanks for that different view on my thoughts.

I do, I think, so we already are two

May be I’m guilty of confusing people by not clearly differentiating between these two different issues.

The tool width correction might enhance precision of seeding - first step.

I may then - second step - use recorded tracks to follow with hoeing.

But as long as my over 40 year old Fendt GT carriers are working, I’m fine to hoe with manual steering - if only seeding is previously done with as litttle track alignment errors as possible.

I think it boils downt to the decision whether I 'll go with wide rows on ridges, or stay with my current 22cm flat seed system. I’ts a bit of circular argument, because I think I’ll need RTK precision for ridges in side hills (but may be not widht correction)

On a 60 cm wide row system, I think the allowable error is much higher than at 22 cm flat seed, I’d get a new machine attached at 3-point links, and presumably I’d start testing with a 3m seeder. So in that case I’d drop (or at least postpone) the idea of sidehill widht compensation.

When I keep my current machine, 6 m widht, trailed Horsch about 6 m long, …

… in that case, tool steering would be quite on top of my wish list.

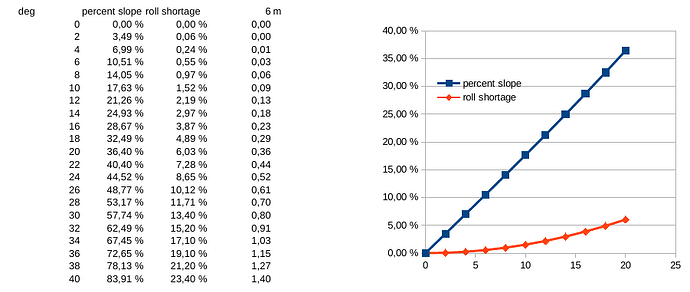

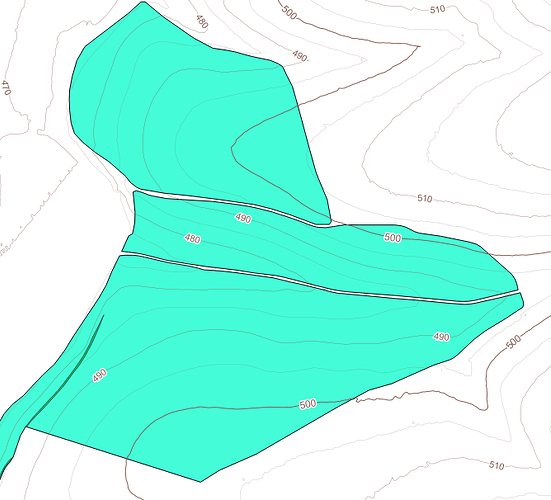

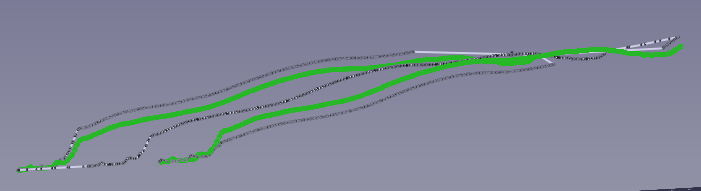

The sh… images above result form manual steering at seeding where the seeder makes unexpected shifts. It’s only a rough approximation which assumes that tool drift ist proportional to side slope. If it where thus, differential error, to a great extent, would compensate itself. But in reality, there are different soil conditions, minor tracks from previous operations etc.

Hardware for U282 with dual antennae is a nowbrainer nowadays (if it works - have just found it in a parcel half an hour ago), so no reason not have one on the tractor and one on the seeder. Boards are made by JCLPCB in batches of 5 anyway - so skd of in surplus.

For software of tool control, there were discussions along a dev version of AOG. Thus I expected do dive into the rabbit hole. Really would be great to safe that time for the weldable hard hardware.

Well it’s a as simple as a simple cos.

But an old wisdom in IT says that the core algorithm takes 5 % of the effort and 95 % of the budget. User interface takes the other 95 % of the work and the other 95 % of the budget.

I know. Don’t need RTK to learn this.

At this argument I think the reason for premapping is culminating.

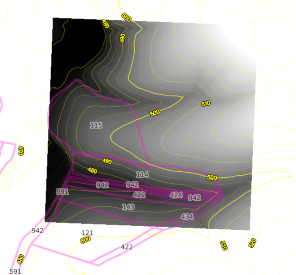

Another reason for premapping is my idea of “nearly contour farming” with ridged systems, to ease erosion. This imho calls for a GIS-CAD GUI, where all the extra math is built in, but the user can focus on tracks as straight as possible, fit to field boundaries where possible, avoiding long wedges at the headland, avoiding water sacks, … and the math is doing it’s job in the backgound.

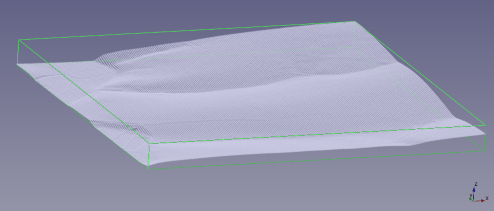

I started explorating FreeCAD over there

https://forum.freecad.org/viewtopic.php?t=97479&start=10

since it has a quite open interface to python, and since I’ve already implemented a FreeCAD workbench, enxtending it’s capabilities.

FreeCAD has a rich inventory of CAD tools, such as 2D-Offest lines, import of DEM and shape with field boundaries, B-splines for 2-times-differntial pathes (i.e. low speed on the steering wheel), interactive sketching, powerful solver for sketches for 2D-constraints, …

May be another Platform would be QGis, where all the GIS stuff is readily availble, but I haven’t even tried their CAD nor their python interface.

And I still don’t get rid of the feeling that I’m going to reinvent the wheel…

So:

Is there any tool for premapping tracks lingering around already?