Yes rated in current, because then temperature/resistance in coil, does not influence the flow at specific oil viscosity. But coil is not different if rated in current or volt.

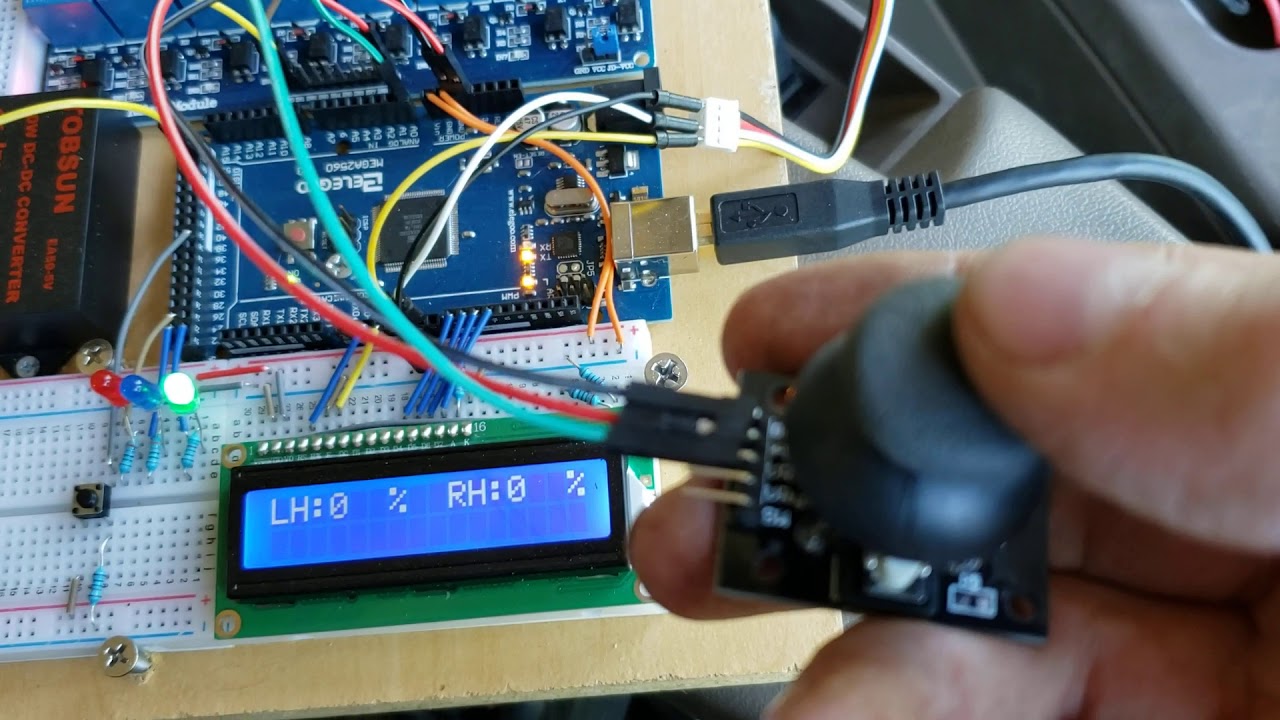

I got a Cytron MD13S and built a PWM valve controller using an Arduino, a joystick, and some other parts I had laying around. With this, I was able to successfully control this valve and steer the tractor with the joystick.

I used the Arduino’s normal PWM capability to drive the Cytron, and connected a joystick to control the Arduino output. I set up a relay to power the “Enable” coil with constant current. It worked very smoothly and I could move the wheels very quickly with a 100% PWM signal. I am expecting AOG should be able to work just fine with this valve.

Video:

@rynthln, did you ever get AOG working on your tractor. We are trying to set up our 8260r, and it appears to have a very similar, if not the same valve. Since it is out main tractor, we want to run it side by side with our greenstar for one year, so we have a backup if there are a few bugs to work through. Do you think it would be possible to tee into the existing harness, instead of unplugging it? What would be the best way to keep from back feeding into the greenstar harness?

We have an 6155R at home, also with the John Deere Valves etc. I have not tried it, but i think it would be best to measure the Resistance of the Valves and plugging Resistors with the right Value in tho the Factory Harness. Therefore the Tractor doesnt know its not anymore connected to the Valves, and then you can Plug in your Harness.

But maybe John Deere does not check if the Valves are connected, then i would simply use a Cap that you can plug in your Harness and seal it up.

I haven’t tried it now but that’s probably how i would attempt it.

Let me know what you think of this idea.

Yes I think that’s a good idea. What I would like to do though, is have have both of John Deere system and the AOG system hooked to the valve at the same time,and then have them on a switched relay possibly, so that when I am in the field all I have to do is flip a switch and I can switch between the John Deere system or the AOG system. Do you think there’s any way this could be accomplished?

I can imagine it would work (then you would need this three times, one for every valve) like this.

But i don’t know if the Tractor likes it and you need the same Voltage when you share one Pin of the Valve, otherwise you could blow a Ecu or your Pcb. But i would avoid using something like this and rather build a more complex Schematic that is also safer, and that separates JD completely from AG.

I definitely don’t want to blow the ecu or something! Maybe @rynthln will chime in yet, but wonder if the standard v4 ino will work without any modifications?

Hi has anyone managed to connect into the John Deere auto steer loom and use aog successfully without upsetting the tractor and creating fault codes?

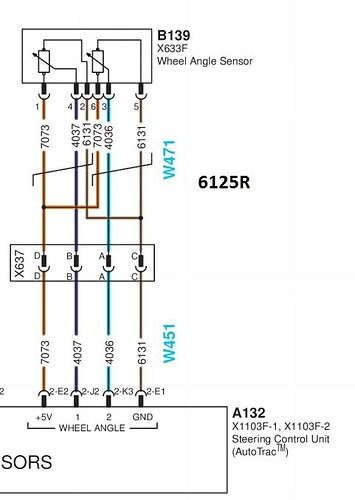

Yes. I have successfully run JD valves with AGO multiple times. It’s very simple, just connect the danfos valve actuator e.g. to cytron and select danfos in the AGO settings. You will find everything in the support files. You can also easily connect the factory steering angle sensor to AGO.

It’s a fema auto steer valve I have tractor is a 6r 175 it’s 2019 build. I take it your are wiring in direct to the valve and the WAS and not going through the can bus? Are you splicing in or making up y harness to keep tractor still connected? Would you know the pin outs for the WAS and the steering solenoids? Thank you

Here a photo from the Fema-valve.

Left solenoid: Turn left

Middle solenoid: Turn right

Right solenoid: Enable solenoid

Have you managed to connect into the Was and the fema valve yourself and run aog with out getting fault codes up in the cab? Thanks

Do you have an SSU module installed? Occurs to me that it could be unplugged. I understand it’s mounted under the rear exterior panel below the rear window on most models. It’s connected to both the tractor and the implement buses. On my tractor it’s tied into the Implement bus through a pigtail at the ISOBUS plug on the back of the tractor. I haven’t looked to see where the other bus plugs into it.

If the SSU is completely unplugged, you shouldn’t get any error messages when sensors and solenoids are unplugged.

I have an error message at motor startup, because the original valve plugs are not connected.

Looking at that pinout, I’m wondering if we could run two plugs from the WAS - feed the 5V in from AOG, then take Signal 1 to AOG, and take Signal 2 and duplicate it to the original harness for 1 and 2. That way, no errors for it being unplugged, and you get the “both signals are in agreement”, so no errors. Would that be right?

I would have to check again for sure, but it seems that I remember signal 1 and 2 being roughly opposite of each other. (For example, signal 1 would be 5v at full lock right while signal 2 would be 0v at full lock right)

You could copy the idea from cnh t6 175 / puma 230 (see other thread here on forum)

They can go with a Y splitter of signal , and connect one end to was in on pcb. Another Y for GND to low on was in.

Ah yeah, that makes sense, thanks

Hello, I have a short question regarding connecting the coils at the original John Deere autosteer valve (Fema-valve). For each coil it has to be used a delphi connector with pin A and B at the harness. Which pin is GND at the different coils and which pin gets the PWM signal (at the two steering valves) / constant voltage (at the release valve)? Is a wiring diagram available?