I don’t know if there is a good way to fit an SP10-47C.

The priority valve would be for the SP10-5x serie.

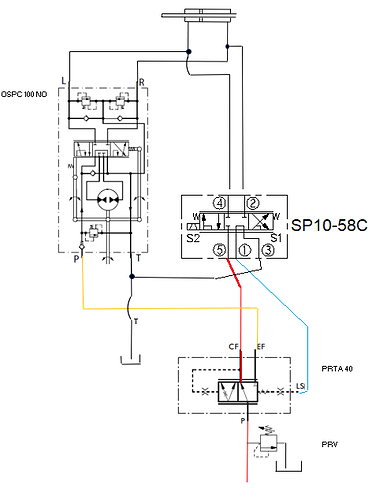

This is the way LS orbitrol are mounted on OC systems, I have this setup to control a blade on remote control, it works flawlessly.

There is an old thread about it, sadly most images are gone.