Theoretically, it might work. In practice, it may not steer smoothly. Prop. would start to open with 75 bars to start. This is a big pressure difference, it will jerk. I use compensators thanks to which I have a delta of no more than 6 - 8 bar and then it is ok. The smaller the pressure difference, the more accurately you can control.

A priority valve or a 3-way compensator will definitely be a better solution.

What is the availability for example EC12-42 80psi (like Baraki is saying, replace valve A in your drawing)

That’s exactly what I’ve been looking for! Thanks guys

I spoke to a hydraulic supplier today who gave the classic ‘can’t be done’ attitude when I asked him about priority valves. Hence I was looking at the wrong end of the valve range.

I’m also surprised how low your pressures are. My setups on CCLS systems seem to work well at full system pressure.

I’ll see if I can find a non-hydraforce version as the lead times are ridiculous, as usual with HF.

With Ls the pressure builds up gradually as needed, in the configuration you propose you would immediately have a shot of 70 bar. At the beginning of my journey, I made a system in which the excess oil flowed through the overload valve, i.e. the system was under pressure all the time. The steering worked, but there were splashes, such a system is also sensitive to changes in oil temperature.

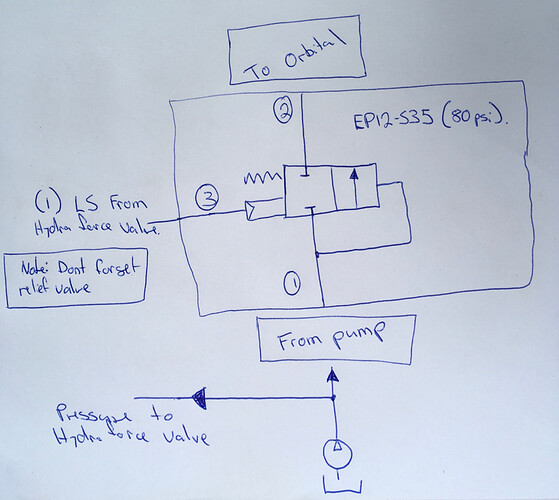

Just another option for replacing valve A in your drawing EP12-S35 (logic element pilot to close) little bit like the way your trying to do it but different configuration.

The LS line must bleed to tank somewhere too if not done inside your hydra force valve.

![]() Is Ok.

Is Ok.

I am sure your design will work.

My Hürlimann have a OC system like yours, where oil flows from orbitrol to oil cooler in front and then to gearshift, so in your system you have the pressure you set on A, and the relief valve inside orbitrol still works as normal.

My setup is with 6/2 valve (placed like Commonrail did), a 4 port Cetop proportional valve with a relief valve in the block (not even needed because I do not have the EP12-s35, that will block oil to orbitrol when Autosteer goes to full Left or R).

Like you I T in before the orbitrol but only use the pressure that the gearsystem create (minimum 17 Bar on your tractor) and then direct to T from cetop.

Disadvantage of dumping to T from steer valve, are some rare pressure drops in gear system, if gearshift are activated same time as heavy autosteering is done. Another disadvantage is that the 25 Bar I have are not quite enough to do narrow U-turn, but AB line is good.

I have tried with normal AB valve and it works, but the proportional valve I have now is better ![]()

Found a pdf I put on combineforum 2 years ago: HYDsketchLarsVest (6).pdf (333.4 KB)

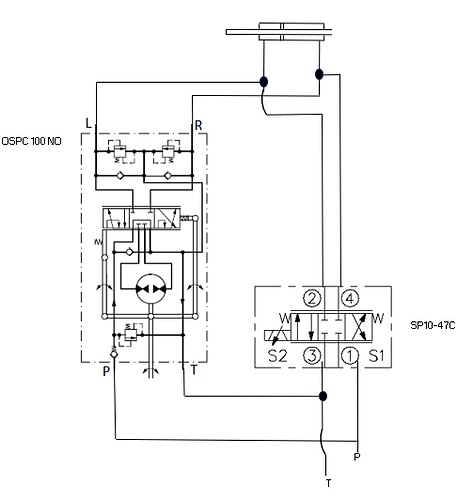

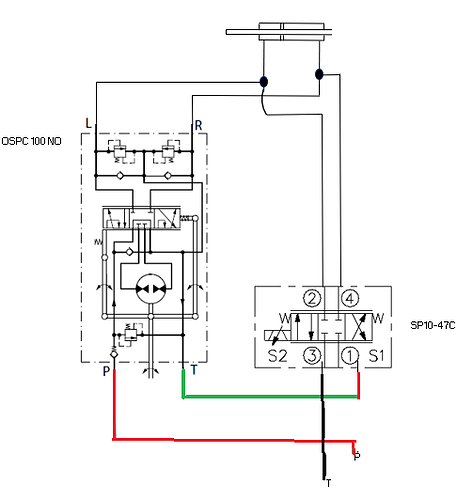

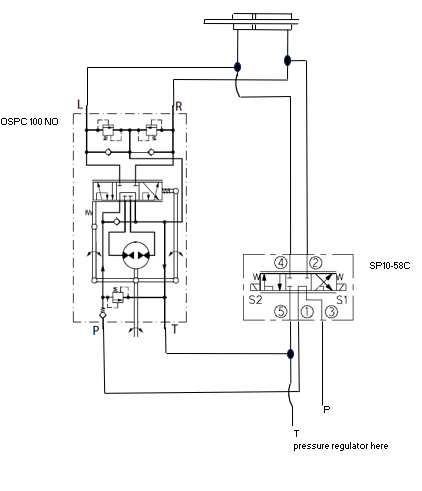

I was wondering similar connection like You, but without 6/2 valve since I have Danfoss OSPC100 ON open center, no reaction orbitrol. I made T-connections for the steering cylinder left and right. Then I T’d also pressure from orbitrol supply and the tank line I connected at the oil cooler… Then I learned that there is no pressure for Hydraforce SP10-47C since at the orbitrol is releasing oil to return gearbox thru oil cooler. When I was pressing manual control switch at Cytron and then turned steering wheel just a little pit wheels where turning alright. Now I am wondering the easiest solution to get it working and utilising as much this non working setup.

I have tank line from proportional valve direct to tank. If as you then no pressure difference to drive the autosteer.

The loss of oil is so little that gear work ok.

I this way there is no tank line open thru SP10-47C valve.?

SP10-47C indeed but the sp10-47c is a closed center and not directly compatible with an open center opt for an oc model

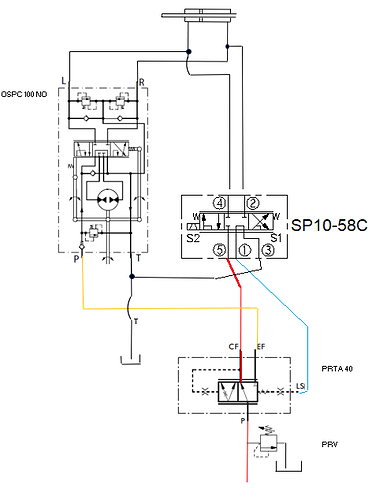

It might be the case. I still try to figure out if it is reasonable to use the valve I have. Maybe I have to buy SP10-58C instead? This kind of connection might work with that.

shock valves will work in orbitrol and additional pressure relief valve would be added before SP10-58C

I am not sure the specification for sp10-58c, is saying OK for using the Ls line as P input.

I suppose you have a HI Lo electric shift on your tractor, just like my Hürlimann (It has Hi Med Lo electric shift.

So I would just use the schematic you see in my post just above your first post here.

You can drop the 6/2 valve and just manually help steering if needed under U-turn.

For return to Tank I removed one of the plugs at gearbox/hydraulic box at rear of tractor.

Because I have the 6/2 valve I can give full pressure when needed for U-turn with heavy front roller Just by holding the steering wheel a little by hand (I have not yet a pressure sensor to cut off Autosteer) but normally it is not needed.

Have never had a problem with shifting between hi med low driving along the field.

Here is an old video driving the Hürlimann Microsoft OneDrive - Access files anywhere. Create docs with free Office Online.

Experimenting with Low max on AOG v4 (and yes WAS not Zeroed correct in INO so had to offset antenna to make passes fit the 12 m weed harrow) 9 km/h

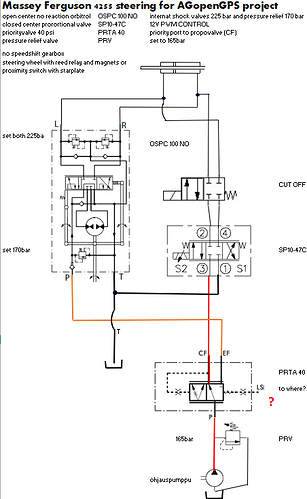

To use a SP10-58C you can use a priority valve to feed it, like the M+S Hydraulic PRTA40

feeding just the amount needed to the valve, giving a good control of the cylinder.

One down side is that the valve will have priority over the orbitrol in case of malfunction, you should have some protection (like 6/2 or on/off valve) against this.

Thank you for update and link to video it was looking good harrowing weed. My tractor does not have electrical hi low gearbox just a manual. I will still try to utilise SP10-47C hydraforce.

Something like this you ment? Sorry for my snipping tool and excel drawings ![]()

Where to connect priority valve LS line?

added pressure relief and cut-off valve

I don’t know if there is a good way to fit an SP10-47C.

The priority valve would be for the SP10-5x serie.

This is the way LS orbitrol are mounted on OC systems, I have this setup to control a blade on remote control, it works flawlessly.

There is an old thread about it, sadly most images are gone.

Okey that seems to work like this? When you steer with pwm coil S1 spool will move left from port 5 oil pressure goes to 2 and 1 , same time port 4 deliveres return oil to 3 continuing to the tank .

The port 1 will sense the pressure in it and passes it to LS port of PRTA it will keep spool of priority valve at left. When releasing SP10-58C S1 to the center Priority valves ls line will evacuate oil to tank thru port1 and 3. Pressure relief valve will open shortly until Priority valves spool will move to to right after short delay caused of nozzle in impulse line of priovalve.