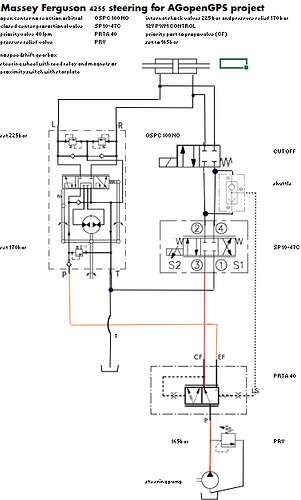

the priority will always give just the amount needed to CF, just enough to make the cylinder move at desired speed.

In normal operation the relief valve will never open and you will not have pressure spikes, it’s very smooth.

Relief valve will just open if you reach the end of cylinder.

Pat are right, but as extra info: There are no springs inside PRTA 40 so the LS line just pushes prta left at just the pressure needed to push steering cylinder. As soon as SP 10-58C is back at neutral (port 5 closed) prta moves right to open freely to orbitrol through EF

But I believe you already have sp10-47C valve, so you can make the Ls line with a shuttle valve like this: LS SERIES HYDRAULIC LOAD SHUTTLE VALVES | F E R - R O Hidrolik Pnömatik Makina San. ve Tic. Ltd. Sti.

A to Ls on PRTA (your ? mark in drawing) , X to port 2, Y to port 4 of 47C on two

Tees between 47C and the 4/2 Cut off valve you have in drawing

Thanks for clarification . It is pleasure to hear that ![]()

Do you remember did you use spring at ES or LS port of the PRTA40?

Are those orfices inside changeable if needed?

Hi Lars we are getting there with you and Pat

Great so it looks lik this:

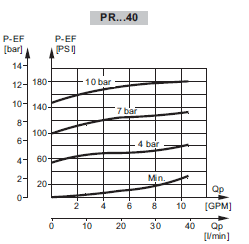

There is also three different springs available 4;7;10 bar for Priority valve.

Flow guantity is 40 lpm and it seems to be enough since pump can produce 25 lpm.

PRTA40/? if spring is attached and needed.

I think your drawing should work.

About pressure spring, I am not sure how it would work, when orbitrol is OC , if it was CC then you could make certain that there were always some pressure there.

For a start I would not use the spring.

The pressure spring is going to set the flow through the SP10. You’ll most likely want 10bar.

Roughly:

4bar = 12lpm

7bar = 15lpm

10bar = 22lpm

Some other points:

- You should really pressure limit the LS line so it’s max pressure is less than the main relief valve, then you will always have oil flow at orbital if the auto steer valve is dead headed.

- The LS line needs a small vent to tank so pressure can’t build up and keep the pump pressure high

58c version would be much better than 47c but I assume you already have this valve?

Yes you are right I already have SP10-47C.

Still missing:

priority valve PRTA40

4/2 cut-off

Maybe I have to consider adding orfice for LS line to leak to Tank line

Maybe the spring can be put at both sides, but the diagram above set pressure for EF line

It would nice test this with some kind of fluid simulator app.

As I understand 4 bar would always give 12 lpm to orbitrol. So no oil to autosteer valve at low engine rpm.

@CommonRail is right about about LS line vent and pressure limit on LS

Yes your setup will need a small orifice to blead the LS line, I had to add one for my SP10-57C.

A relief valve valve on LS line with a lower setting than main will permit to (almost?) never open the main relief.(Experts would say main still have to be there?)

This is for safety for the driver, the hydraulic circuit could work just with the main.

I will have to check for my priority valve setting but I would say 7bar would be right since 15Lpm is enough for autosteer.

Yeah this will make a lot of component and hoses!

No, all the flow not used by the prop valve will go the the orbitrol, unless the main relief is pushed open.

I agree with pat, when CF line is blocked everything goes to EF. But it is not what commonrail writes.

Edit : must admit that I did not understand the diagram. But it may be this way then: The pressure seen in diagram is pressure before valve opens to EF port, and not the pressure at that port. The flow of oil at the bottom of the diagram, is the incoming flow to the valve.

Now I start slowly realising that really there will be quite much additional valves if I will stick with SP10-47C. Might be cheaper to change to SP10-58c? If they are available with in reasonable timeline.

If parts are available maybe it’s worth to change to SP10-58C.

You can maybe reuse the coils and even the 4 holes body for the cut off valve. So just the spool would be wasted.

Edit: maybe the sp10-47 can be mounted with one on-off coil and a spacer to act like a cut off. Since it’s a safety device maybe not my best idea.![]()

That is really good plan.

This training on paper was very useful.