I have been working on setting up three of our tractors with AOG using the V4.5 micro board and have done well on getting the first two setup using other methods besides Hydraulic. I have been working on getting the steer ready tractor going and it all works but I have been having a hard time getting it tuned. One of the issues that it was having right away was that it would steer alright but sometimes I would be off the line and never really steer back. I think I may have figure that partially out with being a problem with the WAS not being fully centered.

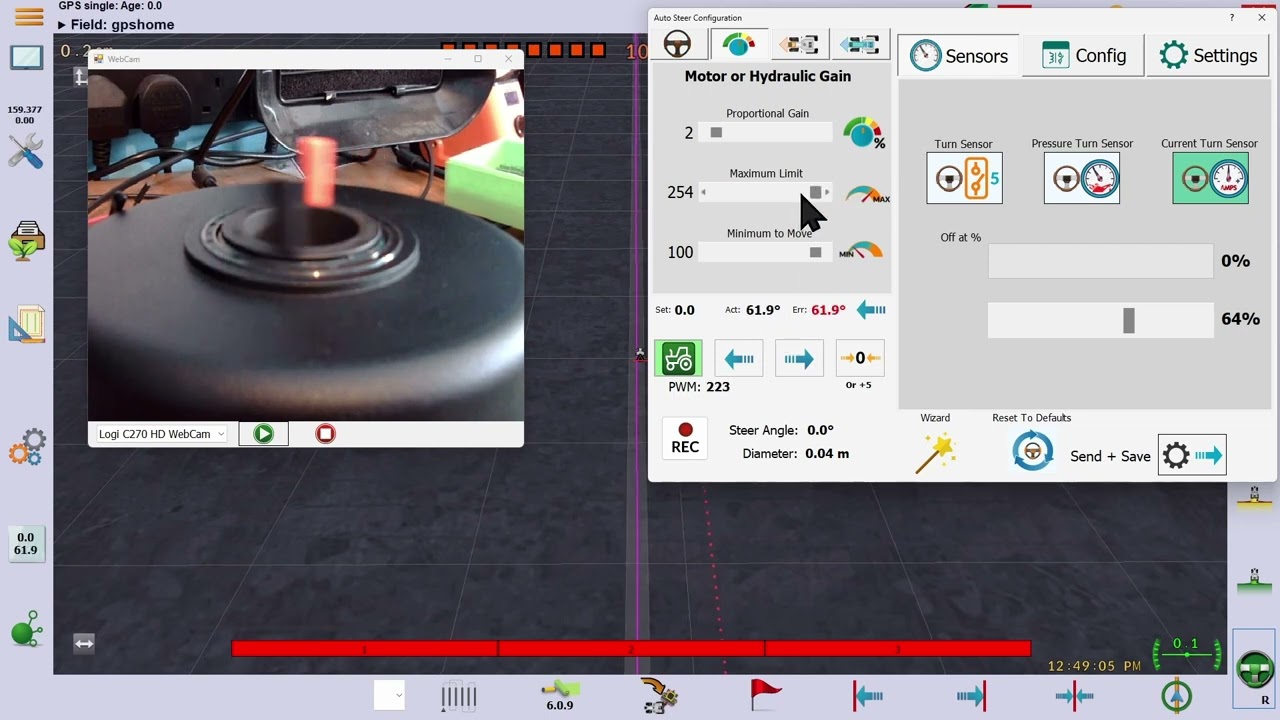

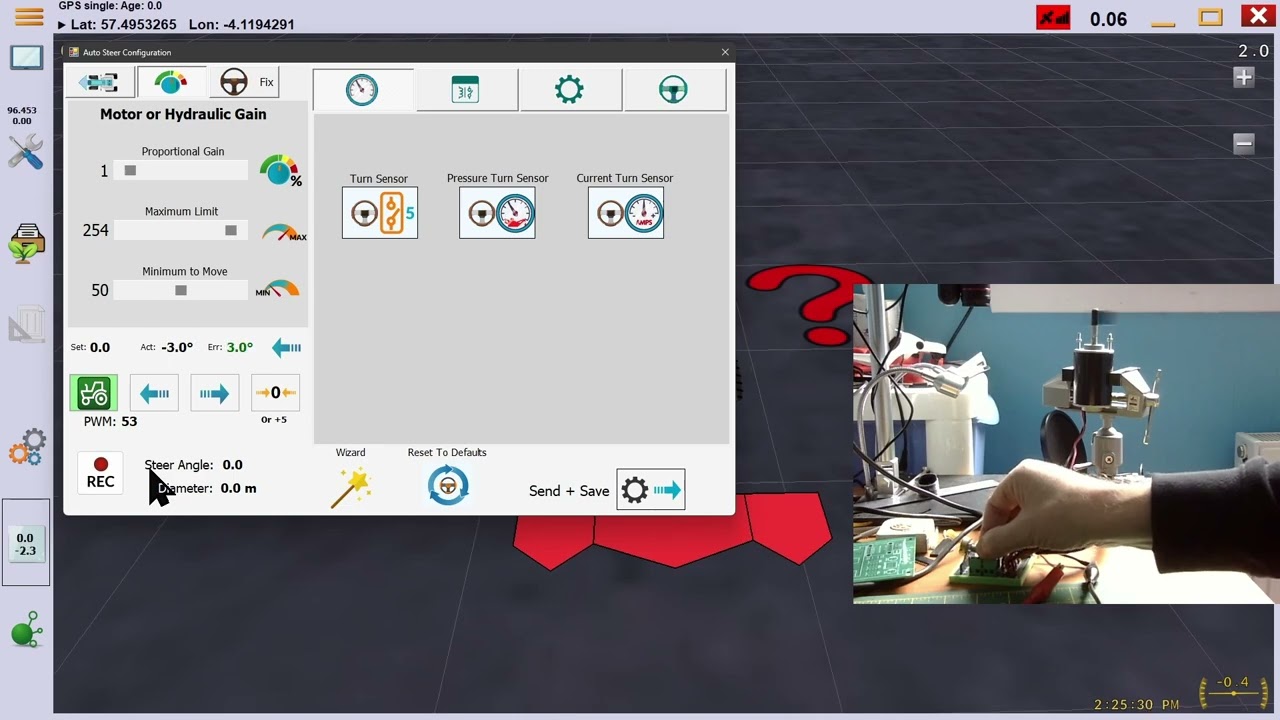

I then tried to go a little faster and I was starting to get a sway back and forth that I have been having a hard time getting rid off. I reviewed the video again and the question I have is does Hydraulic usually have a very low minimum to move? In the wizard when figuring out minimum to move if I would really move the degrees up left or right to create a lot of error I could get the wheels to eventually move but I ended up turning it up as it wouldn’t move with the smaller amount of error. I eventually settled on 50 that seems high to me and now seeing that it shouldn’t really be that high is making me question this.

When I have a moment I am going to jump in it again and play with the minimum to move and proportional gain some more but I was just wondering if there is anything with hydraulic I should look out for that I am missing. Thanks.

As we do not know anything about that valve, then hard to tell.

Somewhere in old video and text, min to move is told to be so high that wheels almost flip (small bits) side to side constantly.

If your valve is mounted with 24 V spools, then min could easily be at 100.

I have not been experimenting with it in AOG 6.7, but remember in 6.4 there was a relation between proportional and min. (More proportional would require little less min to stop flickering of steering wheels)

It is an Eaton Vickers valve that works on 12v. Going to see if I can spend another hour on it today and see if I can get anywhere with it.

Thanks for this. I watched the understanding PWM a few times and it is where I got the question around setting Min to move lower for Hydraulic. I didn’t watch the Explaining PWM again and that pointed out a few more things that I could have wrong. One is that I think my counts per degree is too low as I remember seeing it go into the 60’s so I think will try increasing that to get it lower.

Though I know it isn’t recommended I think I will also try to figure out the min to move while sitting still. The movement was so little when setting proportional gain to 1 that it was very hard to determine if it was moving at all while driving forward. I think doing this might give me a better base line on where I should be and then could try adjusting more while moving if there is a problem. Appreciate the help.