Hi, I’m Paul and based in the UK.

My first post here so thought I’d give a bit of an intro.

I’ve been involved in farming for more than 40 years and I’m reasonably well versed in auto steering, section control, yield mapping, variable rate application etc from an end user’s perspective but generally with the mainstream players in that game like Trimble, John Deere, Agleader etc.

I’m reasonably well versed in C# having created a few applications over the years but not commercially. Most recent project was a Windows application to interface over RS232 with a weighbridge terminal for a friend who has a storage business.

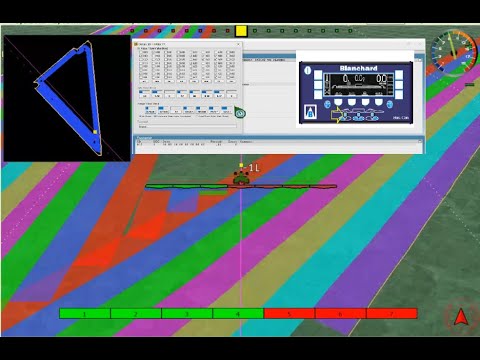

So, having stumbled across AOG whilst searching for something GPS related and given the ridiculous cost of the mainstream gear (specifically RTK unlocks), I started thinking about a possible project so purchased some ardusimple gear and started having a play about with AOG on a laptop.

We have an Agrifac Condor self-propelled sprayer which is currently running SBG guidance (now owned by Raven) for section control, VRA and auto steer.

The screen running SBG is a CrossControl (Windows based) unit with built in CAN, RS232, LAN etc.

GPS comes into the screen over RS232 from an SBAS only receiver.

From what I can establish, section control, VRA and auto steer is all done over CAN bus using existing sensors for wheel angle etc and whilst there is also an SBG IMU on the CAN, I’m pretty sure its there only for tilt compensation.

We recently had to replace that IMU as it had burned out for some reason and the cost of that replacement got me more focused on possible alternatives.

Q1: Whilst I appreciate that some CAN decoding would probably need to happen WRT to section control and engaging auto steer etc, does it sound feasible to get AOG to manage the whole package that SBG is currently doing?

Q2: The sprayer has 12 x 3 metre sections for spraying and we also have a granular applicator fitted to the same machine which has 3 x 12 metre sections and that’s running on a separate screen for section and rate control. Section control on the granular applicator is easy enough as it’s just switched solenoids so can be done with relays but wondered if multiple separate section control has ever been done in AOG?

Paul…