Couple of years ago I wrote some Python code for Raspberry Pi based motor controller. Little over year ago I wrote that on Rust, first ever project on Rust language. I used it for last summer.

Something new for this year. Sprayer pressure controller.

Sprayer control

Sprayer pressure controller is separate feature from AgOpenGPS. Software on Raspberry Pi takes care of sprayer pressure reading and pressure control. One GPIO pin is also used to monitor whether boom is on locked position. Two GPIO pins (relays) are used to control pressure valve.

There are two options for pressure control, constant pressure and speed-based variable pressure.

Sections on my sprayer are controlled with ± 12 V. I use relays to control sections. Pressure sensor takes ground and 12 V and signal is about 0,5 V to 4,5 volts. Pressure control valve is like section valves as it is controlled by ± 12 V. I use relays for that also.

In my setup, this controller replaces controller for my Amazone sprayer.

The black box on top of Amazone conroller is just a switch box, auto on/off, manual section control on/off and sections switches. Main controller and relays are on other box (not in a photo). Amazone controller is just for backup as I used it last year for pressure control.

Other (Windows) software is used to monitor sprayer pressure and to control settings.

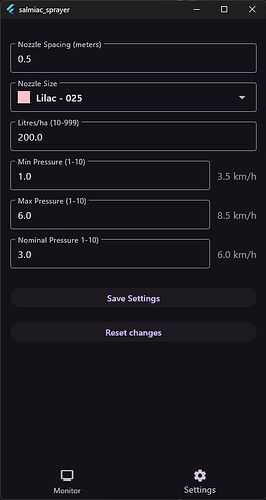

Software has settings screen for nozzle spacing, nozzle size selector, litres/ha, min pressure, max pressure and nominal pressure. Nominal pressure is used for constant pressure.

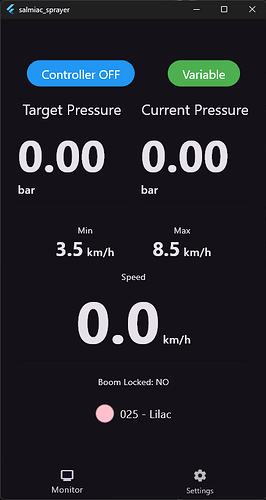

Second screeen to monitor target pressure, current pressure and speed. Buttons for controller on/off and button to select variable or constant pressure. Also indicators for min and max speed for selected pressure range, indicator for boom locker yes/no and selected nozzle size.

I have tested the program on Android phone. The problem with Android software is, as I share wifi from my phone, there might be some issues with ip-addressing for Raspberry Pi controller. And lack of interest of tweaking Android app.

I have not used this on a field yet. It’s not spring yet. But i’ll be ready.