I am working on modifying the rate control add in for a Case IH Titan 4030 spreader truck. I have made mods to the rate controller program but after talking with my brother we will want to set it up for two different spread patterns. One is a 60ft spread and one is a 90ft spread. We will need to be able to switch back and forth. Right now section width has to be defined in both the AOG and the Rate Control application.

I am not up on PGN’s but I was thinking I could send the section data to the Rate Control app from the machine control in AOG. Then I could just select a machine config for 60ft spread and it will set the sections in AOG and in Rate control.

I was thinking that for each section a PGN could be sent with the section id and section width. Maybe multiple sections in one PGN.

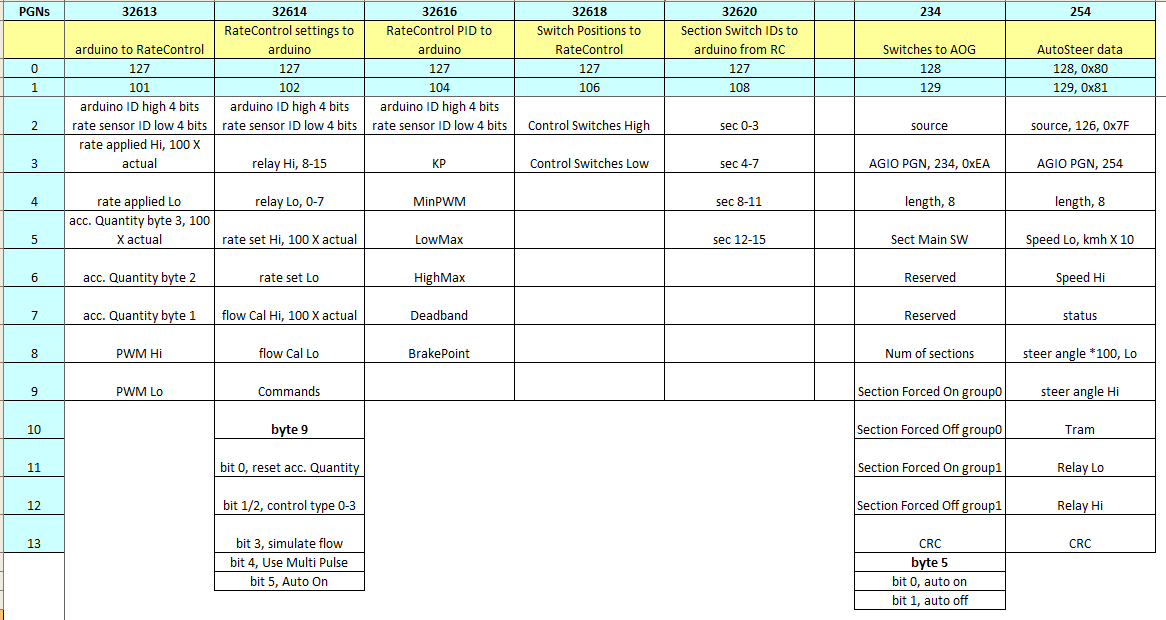

What are your thoughts? As I said I know nothing about setting up PGNs and what IDs are used other than what is shown in the rate controller PGN map.