Can we move this conversation to:

Next step for SMD PCB: Project for an all-in-one compact PCB

Or could the admin combine the two posts.

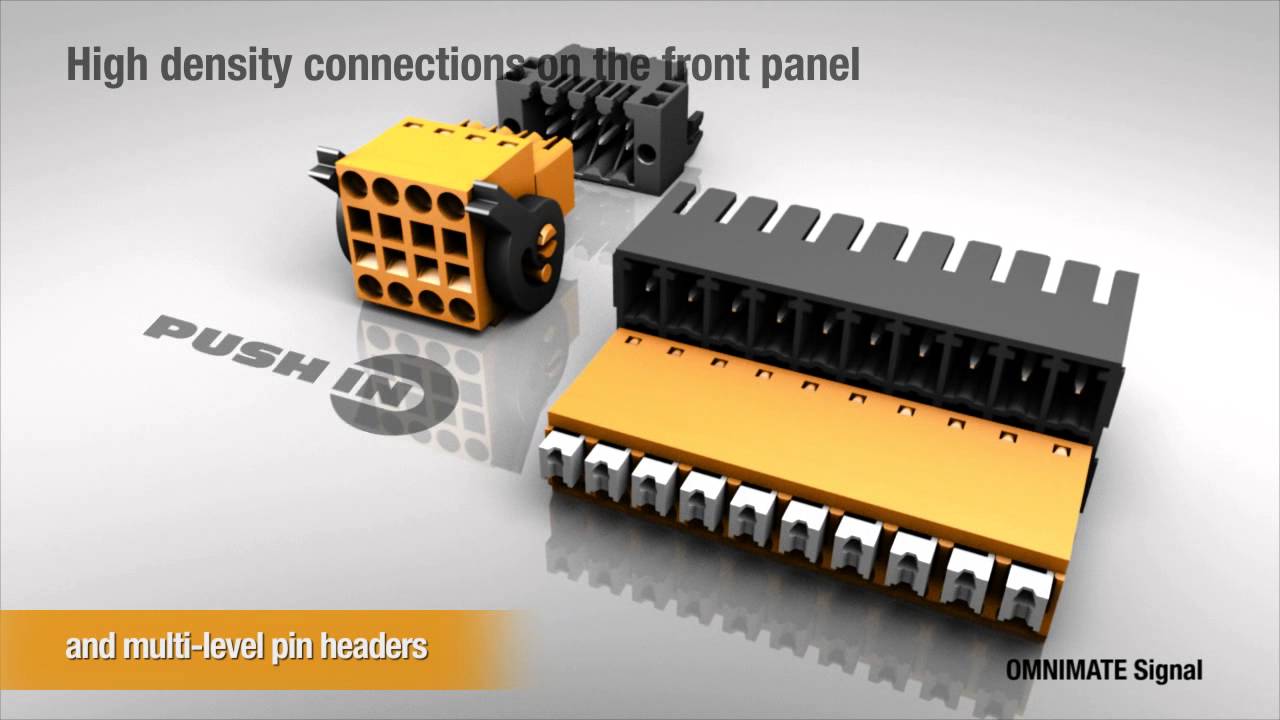

PotatoFarmer, I am currently using the 12 pin Deutsch as well, but GoRoNb wants to use the connector on the other thread. Omnimate. I looked at it, and really like it. A lot like the Deutsch but it cams for disconnect. The Deutsch nearly rips the side of my box out when I disconnect. I think the Omnimate will be a good upgrade.