Below are specifications and information about the Trimble EZ Steer motor.

Weight of assembly including mount/pivot: ~4478 gram

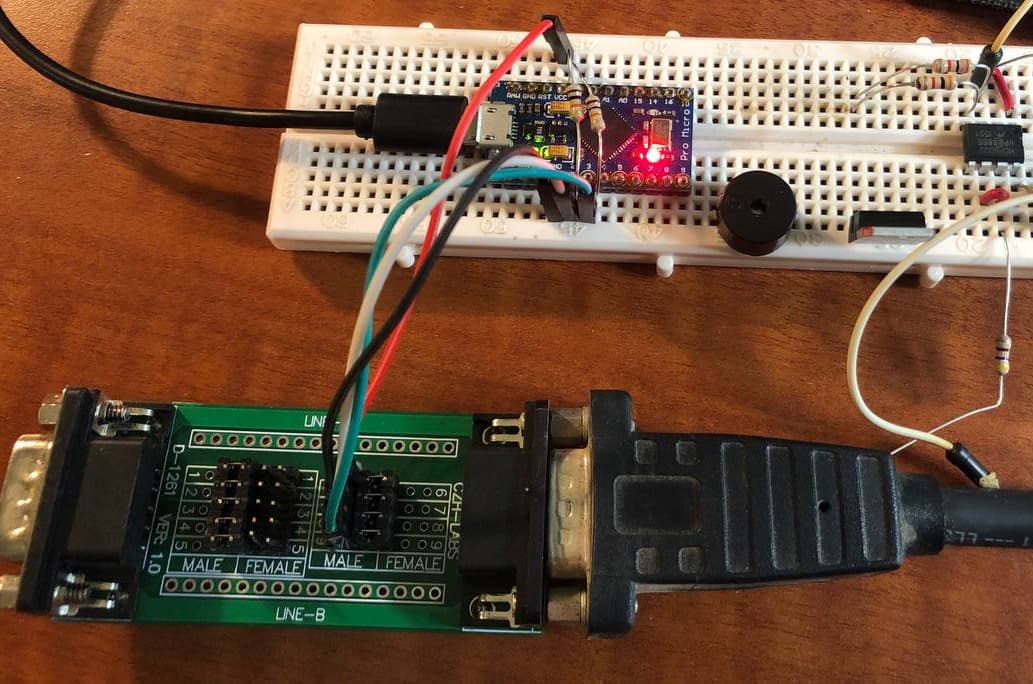

Connector: DB9, male pins

EZ Steer db9 pinout

Pin 1: Motor+

Pin 2: Motor+

Pin 3: Motor-

Pin 4: Motor-

Pin 5: Not Used

Pin 6: 5v Encoder Supply

Pin 7: Encoder Ground

Pin 8: Encoder Channel A

Pin 9: Encoder Channel B

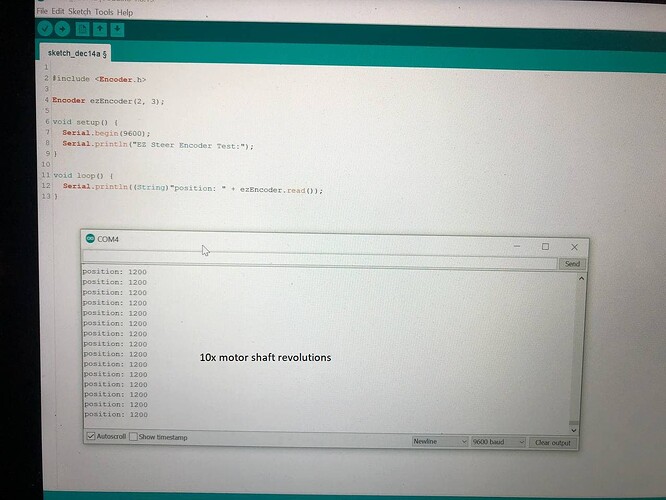

Encoder is quadrature with 120 counts per revolution (each channel is 30 pulses per revolution). Channels are open collector output. I used 10k pullup resistors in my 5v breadboard test with an Arduino Micro. The encoder draws 14mA @5v. I have made an additional 3.3v breadboard test with a Teensy 4.1 using the internal pullup resistors. The encoder draws 10mA @ 3.3v.

Cable 18 awg, approximately 14" long.

Motor can diameter: 85 mm

Motor can length: ~135 mm

The motor has replaceable brushes.

The motor bottom has a sticker with number 53058-00 and a serial number. This number is the Trimble part number that is also on the sticker on the outside of the plastic shroud. There are no other motor markings or identifiers.

4x mounting screws, 10-32 thread

The motor windings measure to be 1.9 Ohm.

Foam wheel outside diameter: ~50mm

The foam wheel is marked with T.M. R.C. RACING COMPONENTS. This is a small American company that sells foam wheels for RC pan cars and RC drag cars. I have contacted this company before about replacements but they will only sell the wheel to Trimble directly.

All fasteners appear to be SAE. I would assume that this was designed in the USA.

Voltage, freewheel RPM, freewheel current, stall current

03.30v 179rpm 0.275a 1.651a

05.00v 286rpm 0.338a 2.490a

08.00v 480rpm 0.370a 4.032a

10.00v 610rpm 0.376a 5.437a

12.00v 740rpm 0.412a 6.679a

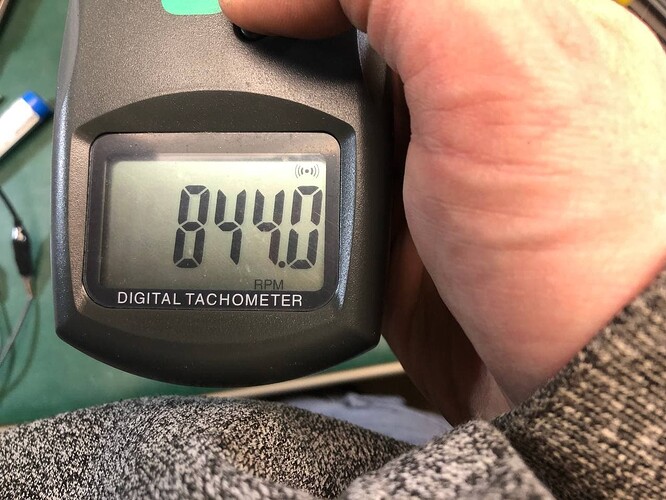

13.60v 844rpm 0.408a 7.520a

Foam wheel diameter

Under the plastic shroud

Replaceable motor brushes

Pulses in 10x motor revolutions

Reading the encoder with Arduino Pro Micro 5v

Motor windings resistance

How RPMs were measured

13.60v freewheel current

13.60v freewheel RPM

13.60v stall current

The other voltage/rpm/current measurement were taken in similar fashion.