What is the minimal % infill that is required after 3 years of testing?

Still testing with the values in the manual, still no breakage or warping on the big gear. Teeth have polished themselves nicely.

TPU gear, have had one failure of the internal key on the Stieger. But this gear was made to be the failure point.

I also would like to purchase a set of the gears and make sure they fit my application , I’m sure they will , then get 3 more sets plus 3 more small gears. I’m in the panhandle of Texas

Thanks

sorry but i am not doing any custom 3d printing at the moment. And since i am located in Canada the shipping would be quite expensive too. I would recommend doing a quick search for companies that do 3d printing in your area, you can give them the the files and tell them the specs you need it printed too.

I appreciate it. A guy got in touch with me earlier and we worked out a deal.

Thank you

Hallo Patato Farmer

I`m using your AOG Steering Gear V3…great Job thanks for this!

Now i need a 12mm diameter hole in the small gear. is it possible you drop the CAD file?

Greets from Switzerland

I downloaded and printed the scaled up gear for the phidgits motor and it’s on an ecliptic rotation. The hole off center. O_o.

I’ll have to fix it in tinkercad. Check your prints to make sure it’s centered. Having it off center will affect

steering.

Does anybody know of a modified motor holder to suit 60ZY105-4.25-2430.

I pucked up the motors believing them to be equivalents to the Phidgets however the gear head is diameter (60mm) as the motor body and thus does not mate with the printed motor holder.

I have no experience modifying STL’s but from a CAD perspective it just needs the inner sleeve taken out of the model.

@PotatoFarmer Would you be able to do a remix of the motor mount without the diameter stepdown in the motor pocket?

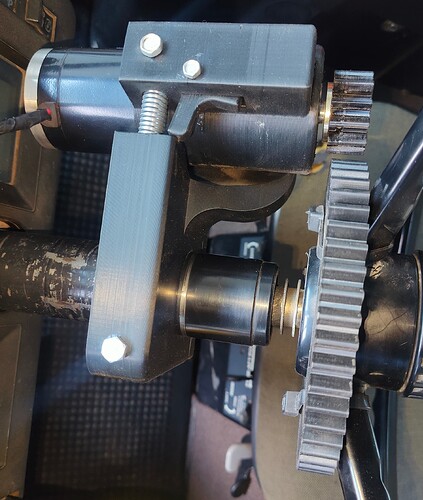

my bracket already exist

I made a gear to fit versatile steering wheel

Has anyone put one of these into a John Deere 40 series tractor yet? I have a 1979 4640 that i’m building a system for. it is our planting tractor, so i’m hoping to get it up and running soon, i was wondering if i should just adapt the universal mount system, or if someone has another one to recommend.

I have designed one that i use on Jd 4760. Not sure how much different that one is or if it would work for you. I’ll attach stl files. you would need a couple springs and a few bolts to make it work.

4760stl files.zip (1.5 MB)

Thank you!

So I have a small question. Has anyone had any problems with the small gear not uploading into fusion in the correct size? When I uploaded it I realized its entirely too big. I looked through the manual to find any mistakes on my end, and couldn’t solve it. Any help would be appreciated!

Did you import it as imperial? I know that can cause issues if the gear was designed in metric(pretty sure it was).

It was imported in metric. I had zero problems with the big gear. I just need to change the motor hole diameter a bit and change the keyway.

Oh sorry, I thought you were importing into slicer… I think I imported it into freecad no issue. Never used fusion.