should have info somewhere of which boards are compatible with how many products and sections. also which boards are rate control only, which are section control only and which do both? maybe im confused

This is the switch I am using.

Looks like a nice option. Twice the cost of a regular cheap PoE switch but then you don’t need a cheapo voltage booster.

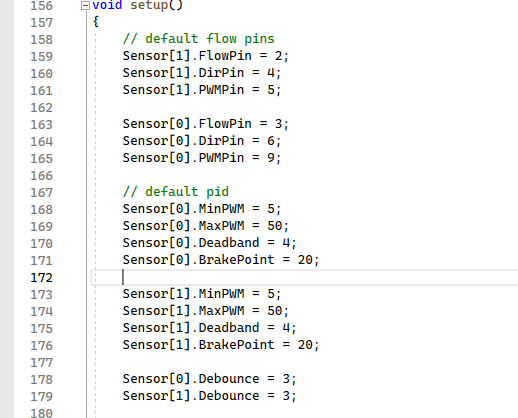

The RC11 pcb can be used with or without a switchbox. It can control 2 products and 8 sections on board. Additional sections can be controlled with a qwiic connector and a relay driver. AOG_RC/Modules/RelayDriver5 at master · SK21/AOG_RC · GitHub

It can connect through an ethernet cable or wifi. Wifi has not been fully tested.

To complete the pcb: a Teensy 4.1, a MD13S motor driver or MDD3A or MDD10A, a 2X3 pin header https://www.digikey.ca/en/products/detail/MTMM-103-10-T-D-355/MTMM-103-10-T-D-355-ND/8214114?utm_campaign=buynow&utm_medium=aggregator&curr=cad&utm_source=octopart

and a 2X3 pin socket https://www.digikey.ca/en/products/detail/te-connectivity-amp-connectors/2314820-6/10494751?s=N4IgTCBcDaIIwHYC0YDMcAsAOMAGJAbEgHIAiIAugL5A

The pin socket goes on the pcb and the pin header goes on the Teensy.

The Teensy code is here AOG_RC/Modules/Teensy Rate at master · SK21/AOG_RC · GitHub

and the wifi code for the on board esp8266 AOG_RC/Modules/WifiAOG at master · SK21/AOG_RC · GitHub

There is no detailed wiki. There should be!

Also a 23 pin ampseal connector AMP auto ecu wire Wiring Harness Electrical connector 770680-1 776273-1 770680-1 | eBay

and two pin jumpers if using wifi https://www.amazon.ca/Gikfun-Micro-Jumper-Arduino-EK1025C/dp/B06XGSZ91M/ref=sr_1_1?keywords=pin+jumper&link_code=qs&qid=1687062613&sourceid=Mozilla-search&sr=8-1

Power can be supplied to pins 16 or 17 or power can be supplied directly to the pcb. There are two places on the pcb to connect 12V and ground with heavier wire.

Hello , i have just replaced an old topcon x20 unit with teensy rate . And im having problems whith rate oscilations . the sprayer has 16 non compensated sections - that part works fine . problem is that the Teejet electric Regulating valve oscilates heavyly @ low spraying speeds or low section count . but it stabilizes quite good at 10-12 km/h . the flow meter is ARAG and gives out 150 pulses , per liter . Even using the lowest PWM value 125 that the motor still turns , produces oscilations . So the question is how could I prevent these oscilations ? Topcon worked fine before .

Can you reduce the output of the pump? It sounds like there is too much flow from the pump to easily regulate. Is it a hydraulic pump? Can the hydraulic be slowed down?

the pump is hidraulicaly driven , but its on /off type of deal so no . but theres a manual passtrough(mixing valve) which could be open more . But The pump barely puts enough flow for spraying @ 14 km/h 200L/ha and 28 meters of width . and theres an interensthing thing that going past 12 km/h teensy current rate displays drops by a 100l instantly , even thoug pressure increases from 4 to 6 . is there a pulse Hz limit for teensy ?

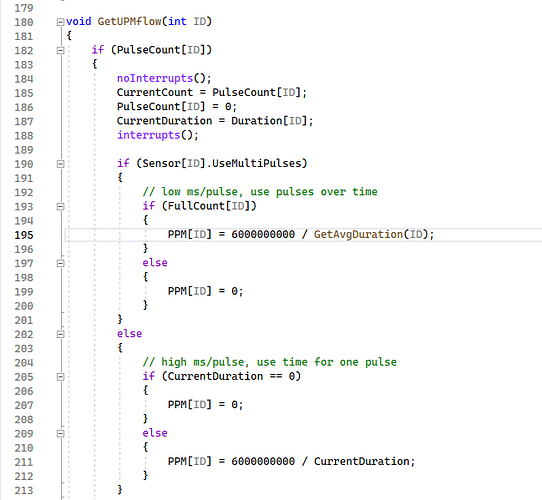

In a telegram conversation with Anma, he also pointed out this problem with the rate going down. He found an overflow in the rate code when the ms/pulse is very low.

PPM is an unsigned long. Your pulse duration is about 0.52 ms/pulse. When 6,000,000,000 is divided by 0.52 there is an overflow. I will change the code to fix it.

This is not the problem of the oscillations though. What version of the code are you using? The newest is 25-Jun-2023 on Github.

It may be the debounce setting in ms here:

If the pulse are quicker than the debounce setting they will be ignored. Change it to 0 to see if that helps.

New branch “FastPulse” on Github. It uses Uint64 for some rate variables and debounce is set to 0.

im using code labeled " Module status pgn." date is shown as last week .

and no matter what code do i use i always get these warnings in my compiler

:

WARNING: library WDT_T4 claims to run on teensy architecture(s) and may be incompatible with your current board which runs on avr architecture(s).

C:\Users\Mr. Marius\Desktop\Tikras rate\AOG_RC-3.5.2\Modules\Teensy Rate\RCteensy\Comm.ino: In function ‘void SendData()’:

C:\Users\Mr. Marius\Desktop\Tikras rate\AOG_RC-3.5.2\Modules\Teensy Rate\RCteensy\Comm.ino:231:14: warning: large integer implicitly truncated to unsigned type [-Woverflow]

DataOut[3] = InoID;

^

C:\Users\Mr. Marius\Desktop\Tikras rate\AOG_RC-3.5.2\Modules\Teensy Rate\RCteensy\Rate.ino: In function ‘void GetUPMflow(int)’:

C:\Users\Mr. Marius\Desktop\Tikras rate\AOG_RC-3.5.2\Modules\Teensy Rate\RCteensy\Rate.ino:250:12: warning: large integer implicitly truncated to unsigned type [-Woverflow]

Omin[ID] = 5000000000;

^

update , I just compiled Fast Pulse code , it doesnt have these warnings .

ESP32 on the back side

Hello,

I’m a it lost with all the information in this thread.

I will try to resume what I understand.

@SK21 did the RateController add-on. It take from AOG the section control and you can manually +/- the applied rate up to 5 product.

@KentStuff did modified the 5.2 AOG to include rates area, but it is just a display thing and it is not linked to anything (I only see a binary build, so no source code? )

there also mention of integration in the future of shd file (so a rates area file) directly in AOG. So I’m guessing more or less do what the KentStuff version do but with more realistic section control and sending rate to the rateapp so that it is automated?

Do I get this right ? if so is there a location/branches where this last part is explored ?

Thank you

The rate controller will take data from AOG and control the rate of up to 4 products and 2 fans. Enter the rate per acre and it will try to maintain that. KentStuff’s modification of AOG reads rate maps and sends the data out as a PGN that the rate controller can read. This will provide variable rate control. It is not available in the newest version of AOG.

When I try a simulation on my computer, I was troubled with aog-rate + ratecontroller.

aog send the section to cut, send also the rate with pgn 230 but it is not a rate per section ( my usecase is kind of on/off so rate per section would be nice)

Do you now where aog-rate source code is ? - or if there are work started to include it on aog, where t may be ? - I got some import issue, (layers appears / disappears, even in the saved rate.kml file) Windows app is not by forte, I work with non gui app like client/server but who knows…

Rate pgn 230 is 5 different rates as a % of the base rate. All the AOG variable rate modifications for pgn 230 are by KentStuff.

In the current state of AOG there is no good way to add rates to individual sections. All sections that are on or grouped are recorded as a large section. In this modification the tool center position reads what zone it is in. The 5 rates at this point are sent out as pgn. The data is recorded on the map as the whole tool. That is the way AOG is built. The shape files have been spoke about for a couple years now. It is available as a test code on github. I have not attempted to modify it.

The shape files have been spoke about for a couple years now. It is available as a test code on github

Do you know where?

I guess you speak about the code you compiled to get the GitHub - KentStuff/AOG-Rate-Apply executable, but if not where can I found the code that generated this ?

Thank you

The shape files are in the dev6 branch on github. Or I should say repository on Brian’s main github page. I think it says something about show all repositories.

Hi team,apologies if this is an obvious to answer question- I cant find the answer on the forum.

Is there any step by step guide to building rate control ?

I have built the V4.1 micro autosteer board and have that installed and working.

I’ve downloaded the SK21 github zip and then I am lost.

I see the modules folder. I am aiming towards a nano version.

I see RC5, RC8, RC12, RCnano. Do we need to get JCLPCB to make all these boards ?

In the RCnano folder there are so many files… what to do with them ?

Thank you for any help.

Cheers,

James.