Used 330 ohm. Thank you very much

Maybe not placed correctly.

when I look at it closer, there’s quite a few things that way

The issue of the irratic rate readings has continued unfortunately.

I have worked out that the pulses per litre is actually 1230 (the tag was hard to read). This puts it under the 50ms per pulse. Having it on that setting makes the figures go crazy most of the time.

The signal wire has a vmax of +8.5, vmin of -0.4 and the rate and speed I am aiming for runs around 330hz.

When flow meter has no flow signal is +8.5v

I looks to have good square waves on my cheapo oscilloscope.

330 pulses/sec = 3 ms/pulse. This may be too fast for rc to count.

Yeah ok.

I found this 10:1 signal divider commonly used with polmac sensors so I might give this a try.

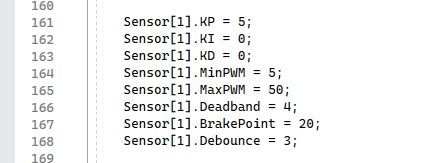

You could try changing the debounce value at line 168 in setup to 1.

You will also need to change the InoID to a different number so that the default values are used instead of the stored ones.

Does the InoID need to be changed to any particular number or does it just have to be different? Ie 25062?

Any number will work.

I updated with the new settings and the rate was stable, not going into 1000s but not always accurate. It would settle on a figure then changing either speed or pressure it would not return to the same figure when speed or pressure returned to original, ±50 or so.

I ended up getting a signal divider and that did the trick. Still with the updated debounce and InoID figures. Havent tried it with default setting yet.

Good that you got it working.

Polmac flowmeters generally operate at 600-650 pulses/litre, but Arag is 250 pulses/litre, now it is clear why Arag keeps the number small. But what I don’t understand is this: 650 or 1000 pulses are a number that a processor can easily count, why should a pulse divider be used?

at what rate do the errors start?

Not sure @whiterose. It didnt work untill i added the signal divider so whatever that did it made it possible for the program to read the pulses. Interestingly the oscilloscope couldn’t get a lock on the frequency after adding the signal divider. It also dropped the voltage of the signal a bit.

I added the divider and put in 123 pulses instead of 1230 and it worked and is quite accurate. Still <50ms setting.

I will run some tests next week to see where the errors start without the divider.

An update. I had success with RC counting my polmac 1230 pulse per L flow meter by using the fastpulse branch and changing the teensy.

It was stable and very accurate. Worked perfeclty after the change.

Thanks for all your help.

You have made a good program SK21, well done.

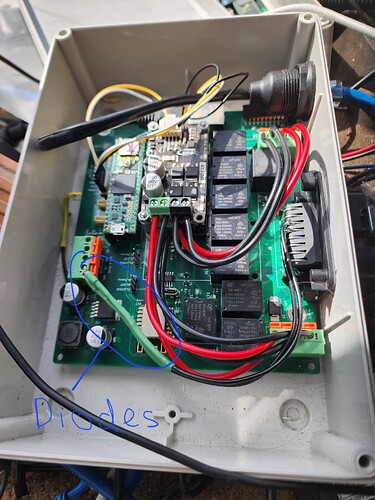

Also a note, I had trouble with the teensy shutting down when solenoids shut off. 2 of the 5 solenoids are these (Teejet - Electric Solenoid Shutoff – SprayTrac) .

I put a flyback diode on the crcuit and seemed to fix it.

On which pcb did the teensy shut down? I haven’t seen that problem.

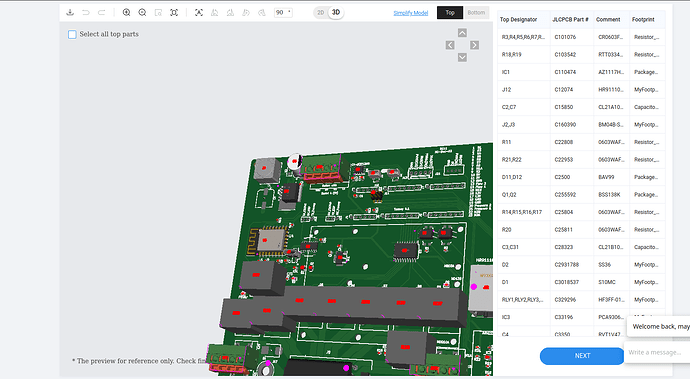

The RC11, 30-Dec-22 teensy board. Pre assembled from JLCPCB.

It was only happening when the master was switched, it didn’t happen when a solenoid was shut off individually.

It shut down the ethernet from the board, I assumed the teensy had shut down but didn’t confirm that.

What had me think it was a surge was that the leds on the relays connected to the two tee jet solenoids stopped working.

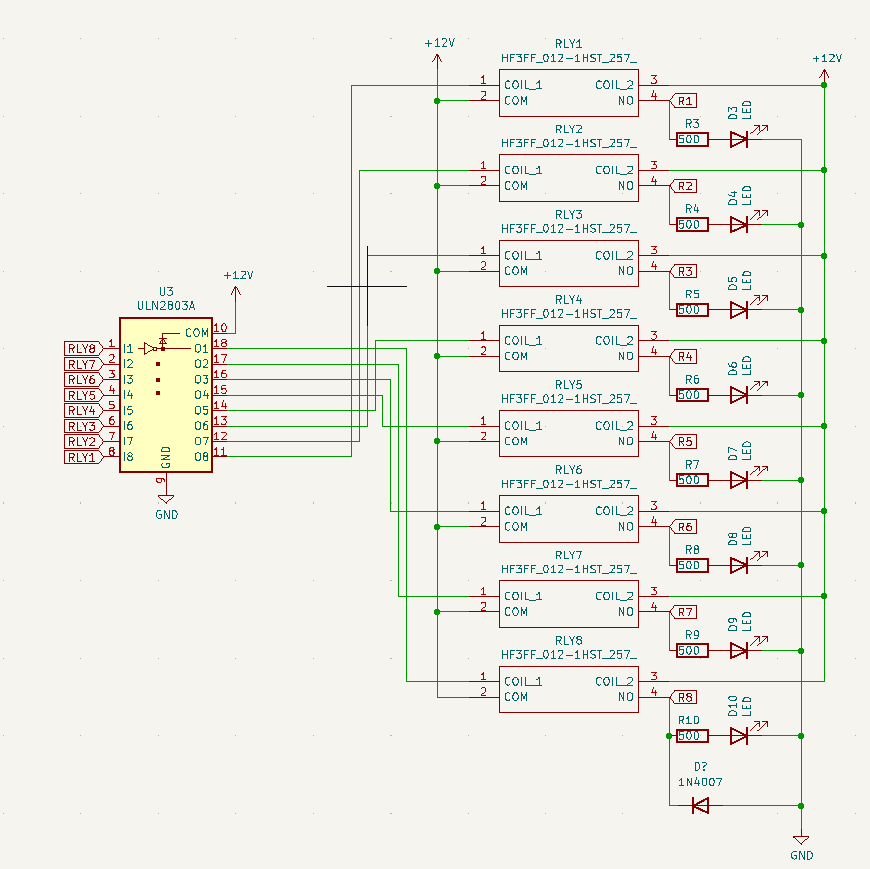

I added IN4007 diodes and haven’t had an issue again.

Is the circuit you added the same as the schematic edit for relay 8? It could be used in a new design.

And it’s possible for DPDT relays? Motor valves needs a reverse polarity