hi,

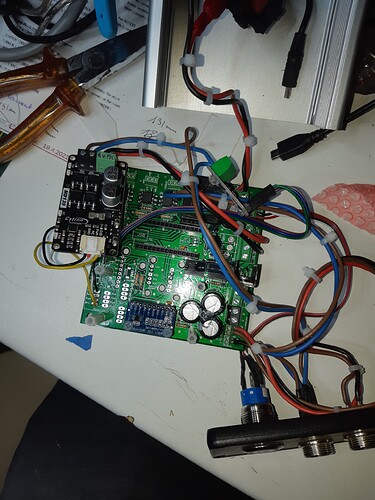

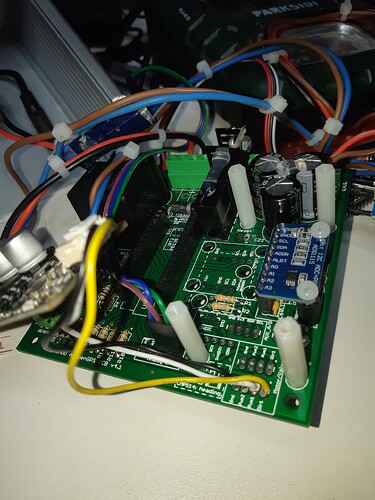

i have reloaded arduinio, check soldering under and upper the ino and ads 1115.

The signal of WAS come on ADS 1115 but i can’t read any rotation of WAS on AGO.

Did i made a mistake with some wires or did i forgot any piece.

To prevent a feed back to MD13S i join it an ACS712

I can’t stop it now…

Have a good day Michel

For cytron backfeed mod you have to modify cytron by removing 2 components and connect NC with wire to that trace.

You also have to connect pwm2 to NC.

Only then ACS712 can work effectively.

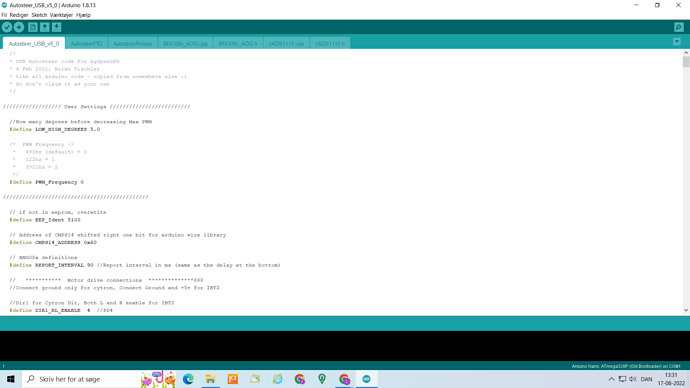

Edited my earlier post, but I still see USB is using v5.0.ino

Have you tested Your Nano, by uploading the “blink” code?

See how on google or arduino forum. (search google with : nano blink sketch )

Does the arduino ino upload to nano without faults?

You write this: “in your supportfiles did you send the 3 files with logo arduino?”

Arduino ino automatically open all the needed files when you open Autosteer_USB_v5.0.ino

So MAKE sure they are all available in a normal folder, And open/start Autosteer_USB_v5.0.ino when you are in that folder (see next)

I once noticed that the downloaded support folder, after it was unzipped, was only read, and not able to write back. (so copy all the unzipped files in the Autosteer_USB_v5.0.ino folder, to a new folder with a name you choose. Should be 10 files!

I DO NOT know if you need any extra files to make the ACS712 work? but maybe you only need to set the numbers in AOG setup area!

Just to make sure, but pictures you posted earlier of PCB, are accidentally without the nano in place

When you click Autosteer_USB_v5.0.ino then my computer automatically open arduino ino , and look this way

The VM files is for Visual Micro, I do not think you need them for a nano.

Hi,

Thanks all of you it will be better now, i re-soldering my arduino and the ADS 1115 (of course it wasn’t on picture…) and now i have got it…

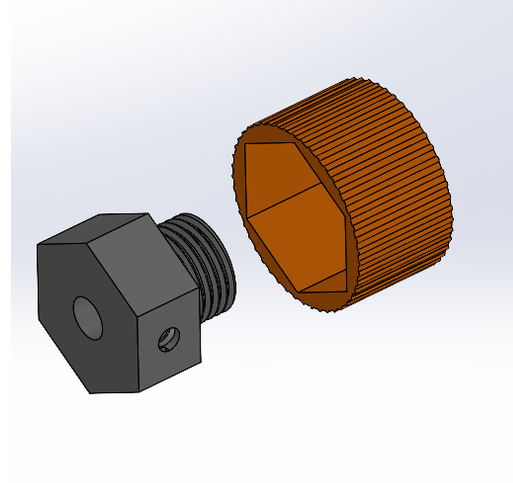

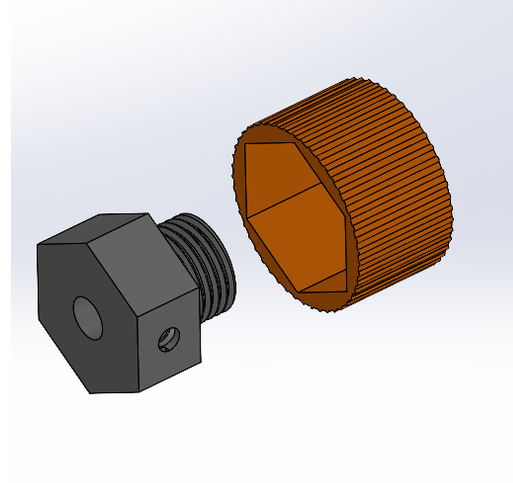

the problem is now the little gear (PTU) is too soft and turn without motor so i try to realise one with PLA.

See you tomorrow for more good news…

Thanks again and have a good night Michel

hello michel

for tpu gear it is better to have the center parts more strong with kind of teeth or hexa square chaper to avoid rotation

i dont remenber but i think you use a similar solution as me so i put additionnal shape to meet some bolt

if you need more tell me …

1 Like

Hi,

I love your idea, but i copy your clutch only, for the gears i copy those of Potato Farmer (fishbones)…

I will made a mix of yours with fishbones with 2 pieces one PLA and exterior PTU in few weeks.

i have to finish to send parameters on autosteer of rover and i wanted to seed rapeseeds as soon as possible.

thanks and have a good day, Michel

1 Like

Hi,

if someone of you is interest i will show you how i made this mount of my WAS with PLA 2 pieces one of those slide inside the other; it’s work for the moment let see…

Have a good day Michel

1 Like