In my opinion, if you’re going to go to all the work of adding all that plumbing and valve, why not just skip the electric motor and add a PWM two-way valve to the system which AOG can control directly?

I considered this as a fairly simple solution with the ls function maintained. Used orbitrols shows up now and then to a reasonably price. Thats why…

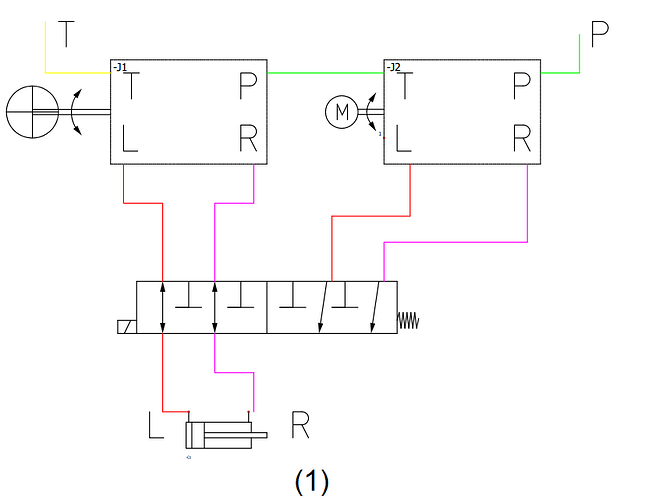

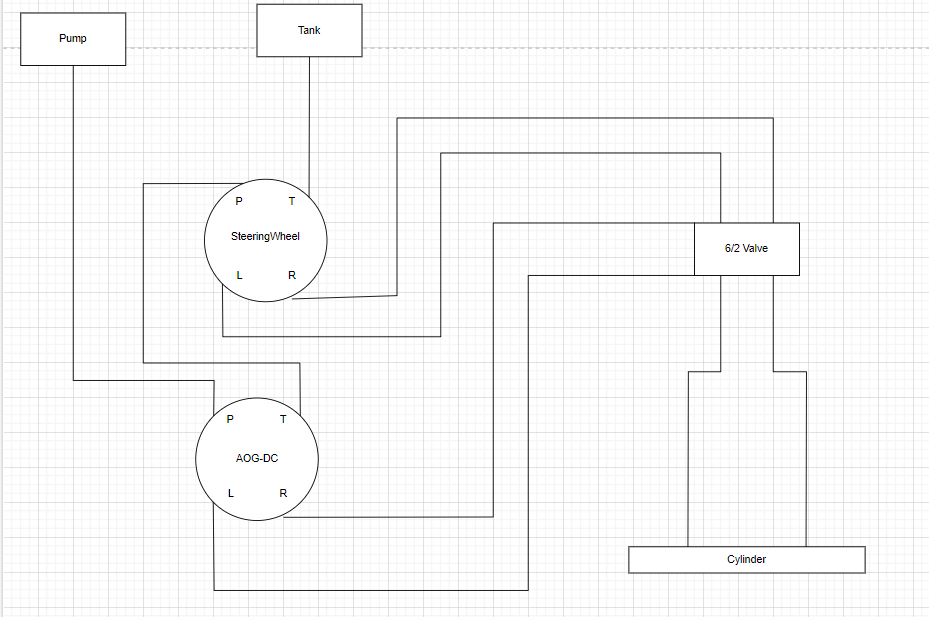

If you connect as shown in the diagram, it will not work well.

Cutting off the P line with a solenoid is not needed because if you are not spinning the orbitrol these ports are shut off in every orbitrol with Ls.

You need to cut off the R and L lines because the orbitrol on the MX is reactive and the steering wheel will turn if you put oil through the tees into the piston lines.

You also need to use a logic valve or 3/2 solenoid valve in the Ls line as by connecting 2 orbitrols with a tee you will never get pressure in the Ls line if one of the orbitrols is not working at the moment.

Thanks for the input. To explain my thinking the cut off valve was just to add safety nothing else.

The manual steering valve is always available.

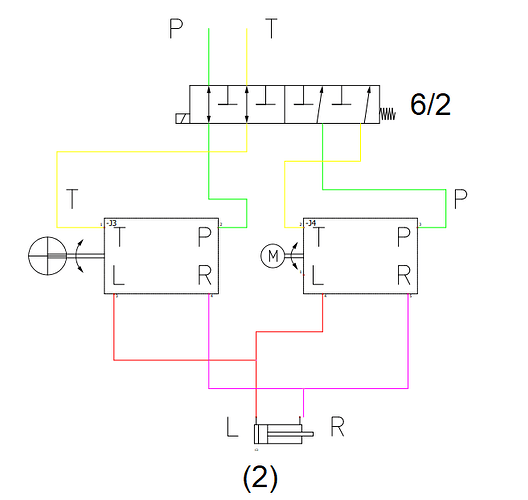

My first thought was to just add a 6/2 valve and choose which orbitrol to use. Since P and T are blocked in the disabled orbitrol the oil from R and L has no where to go. In that case you have to rely on the solinoid valve for safety.

Perhaps closing both P and T in the sketch would work? It would be similar as to my first thought.

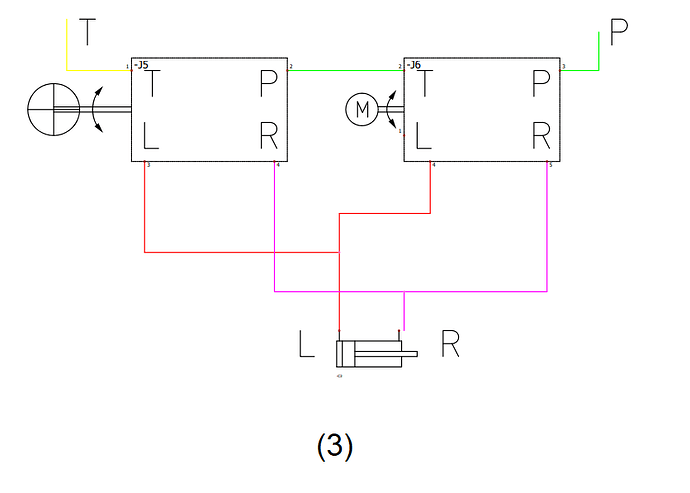

How about flow between L and R ports? In my understanding it needs to be blocked otherwise the wheels would turn uncontrolled.

Regarding the LS connection I thought that if no oil is consumed pressure will be built up in the LS line and lower the flow (pressure) to P. In the sketch there is two LS connections, one on each orbitrol. If the pressure drops on one LS port pressure in P line will rise and the orbitrol that needs oil will get it and the other one don’t. Perhaps I got it all wrong?

I think that this concept is valid, as using electric motor next to steering wheel is basically controlling orbitrol with motor but with extra steps, and possibility of decreasing accuracy with motor holder slack, foam wheel slippage or gears mesh too hard, worn out original orbitrol etc…

As we are achieving accuracy 2.5cm± with motors next to steering wheels. We should get similar results this way or better. With clean cab install, and steering wheel stopped when using auto steer.

System should cost under 300€ with new orbitrol, motor and hydraulic plumbing.

Main concern is safety of this concept system. Is physical switch to cut power to one of motor leads or cytron enough? Or should there by adicional diverter valve to not allow oil to autosteer orbitrol?

ACS712 is already on AiO but it can be used as fail safe if autosteer is engaged when tractor is not running or has some problem. Also need encoder (turn sensor) of some sort on steering wheel for disengaging autosteer.

If all goes good, it should be good mid tier solution, between motor next to steering wheel and proportional hydraulic valve.

I would recommend using a pressure-type sensor because you can install it on the lines.

As you move the steering wheel the pressure should increase, so it will disengage.

I would recommend putting one valve which will switch the oil flow from one orbitrol to the other.

You can have a motor with a higher gear ratio because you don’t need that much speed if you connect it directly. My suggestion would be around 120rpm.

I like the idea personally as the middle solution. Maybe will try it soon in one of my tractors because I have one orbitrol lying around.

I am thinking about adding pressure sensor later on, if this concept is good. For test encoder or just turn off manual.

Yes, I have 200rpm motor available now, but can switch to 76 rpm one if this one is too fast. Good is 100rpm~ but hard to find local, 60-120 rpm is optimal.

Schematic number 1 should be optimal with steer lines of second orbitrol blocked, schematic 2 is for no oil in autosteer orbitrol, schematic 3 is direct tee of L R lines.

If wire for LOCK valve is routed thru switch that will not allow activation of 6/2 valve with out it pressed, it should be same for motor that if lead is cut with switch there should be no activation. With 6/2 valve safety rely on it then, when motor controls direct it rely on motor not starting. With 6/2 both it and motor must get power to have fail of self steering. But if valve is stuck in autosteer its still single point fail, just loss of steering. 6/2 is used with valves already and blocks unused lines so it should be included.

I agree with the first option as well.

For me and my knowledge of hydraulics, it should work like a charm.

I would maybe prefer first from pump to steering wheel orbitrol than to AOG orbitrol.

I planned to order the valves soon so after the new year I would try to put together one that will be switch-activated.

In the future, I plan to add a pressure sensor for automatic disengagement.

This way I dont have to remove any plumbing from original orbitrol, as P L R are available at connections to metal part of plumbing. If orbitrol is hard to reach. But maybe better for P to go first to steering wheel orbitrol, then to autosteer one.

Hello,

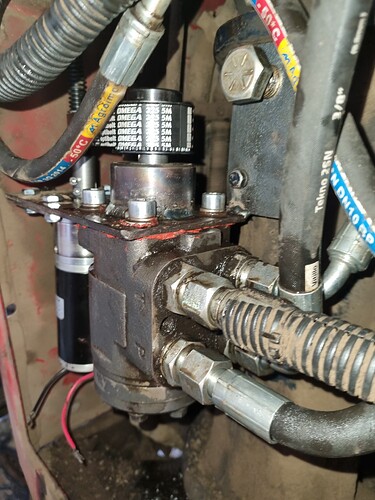

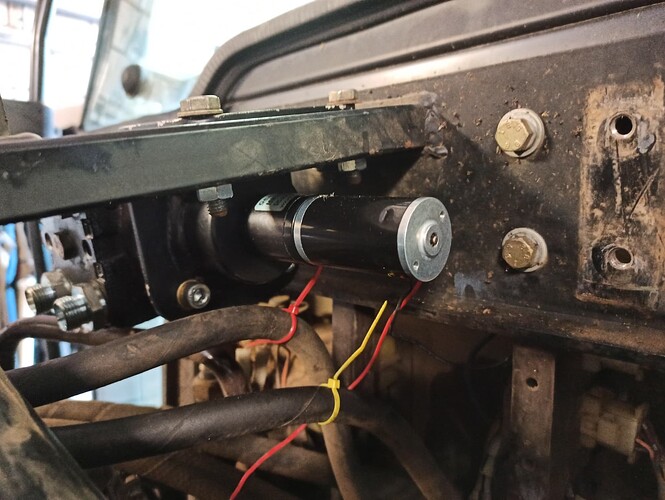

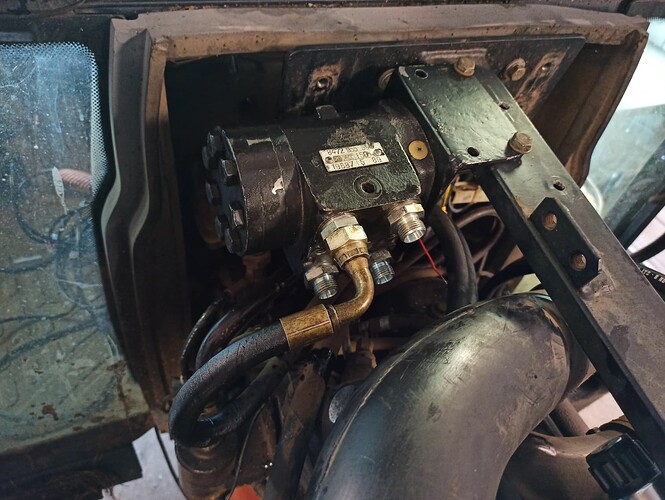

I am back with a successful installation of the second orbitrol.

The previous setup on this tractor was the standard steering wheel and dc motor setup with 3D-printed gears.

Now about the new setup and some challenges.

Materials that I used:

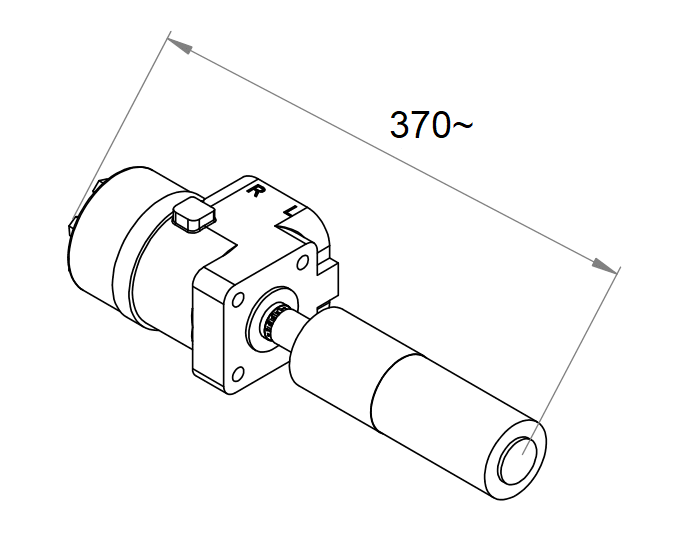

1 - Second hand orbitrol

2 - DC Motor from previous setup

3 - HTD M5 Pulley 14 teeth

4 - HTD M5 Pulley 32 teeth

5 - HTD M5 Belt (25mm width for pulleys as well)

6 - DVS6 - 6/2 valve (24vdc only that was available in my country)

The price for everything was around 300eu.

My idea was to route the pump to the AOG Orbitrol and then to the Steering wheel orbitrol. As of now, I have not noticed any change in the steering being stiffer. The 6/2 valve redirects commands from tractor steering to AOG steering.

Now on to the pictures.

I would like to use a bigger pulley on the orbitrol side so that the rotation speed is around 120rpm, currently, it is around 250rpm max speed. My motor is rated at 1000rpm.

I did not have time to test the system. I just tested it with the arrow in AOG and jumped a couple of times with big angle differences and some small angle differences. Currently, it is looking good, but more about the testing will be done next week.

If you have any questions feel free to ask.

I just finished my second-orbitrol project today. Tests are very good. what I did so far:

bought a

- Used orbitrol (60 euro)

- 6/2 valve new(100 euro)

- An electric motor (30 euro), this one did not have enough power so bought

- Second electric motor (110 euro)

- Some wiring and hydraulic hoses, don’t know the costs yet.

I connected the orbitrols like this:

Tractor is a New Holland L95. Here some pictures of my original build.

After this it did not steer fast enough so I bought a Phidgets 4002_0, 180RPM and lots of torque. I 3d printed the coupler between motor and orbitrol.

First testdrive my fuse blew, now I put a 15A fuse in the line from battery. System works really well, fast enough and accurat. Only thing is there is no take back from autosteer, not yet put a pressure sensor in the system. (wich line?)

A short video of driving the system: https://youtu.be/BLjFjweNqs8

What motor driver and PCB do you use?

Everything stays the same just the motor is connected to the orbitrol.

Board is AIO4.1micro, controller cytron. I drive for an hour today without problem, I know the motor can draw 20A max, more than cytron can handle. Max pwm set to 165

Are you doing anything to automatically turn off autosteer when you grab the steering wheel? Pressure sensor somewhere?

Are you running the Phidgets at 24v?

Not yet. Not missing it for the moment but for safety it should.

Yes, running 24v. 12 was not enough to turn quickly.