Any use to someone?

Some standard can codes listed.

Sorry these Manuals are both above ( Thought they were the same ![]() ) But i will make a video and it will refer to these books for more infomation.

) But i will make a video and it will refer to these books for more infomation.

Communication Manual for the Danfoss PVED-CL.

https://assets.danfoss.com/documents/53748/BC152886483811en-000201.pdf

Operation Manual.

https://assets.danfoss.com/documents/65719/AQ152886482359en-000301.pdf

Both direct from the Danfoss website. They are good to read and have all the ISO standard information.

I have an AGCO Gleaner combine with this valve but the factory analog WAS missing.

I have managed to make the valve steer by installing a PrincessAuto WAS and using @CommonRail 's “Autosteer_USB_AOGv5.5_Valtra” and “Massey_Working_Code_v2”

But now I would like to map better the WAS, because it stop reading about half way on one side.

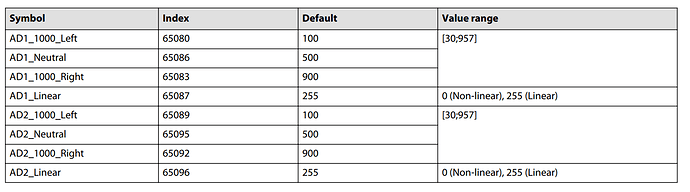

Here are the indexes from the manual:

Can these values be read and modified with an arduino and a CAN shield?

to see it I suppose I must send a “GetParameter” and read a “GetParameterResponse”

To modify: “SetParameter

to save it: CommitData”

Try this folder, use the “Read Parameters” then copy the data to the “Write Parameters”

The data program will let you read the raw AD1 input (Data set 1 I think) write these numbers down left,centre,right

Its made to use the serial monitor to change parameters, send a letter etc to do the task.

Warning: Only use these if you are confident in what you are doing, if you change the wrong things you can end up with problems you might not need.

AgOpenGPS Danfoss Tools_ Arduino Uno.zip (12.5 KB)

Thanks, I will check these inos carefully before using it!

What are the normal curvature values?

With my own WAS I have:

31340 to 32938 from one end to the other with 32350 at center.

But the problem is 32938 is reached about 2/3 way to the extreme, it does not go higher, so I cannot steer full on one side.

First set the left,right,center raw WAS numbers.

Then there is also the actual wheel angle at max value, (35000 is 35deg for example) this will change the scale/range of curve command

There is also the wheel base in there somewhere, this is not so important all it will do is change how accurate the real curve command is in km

Thanks @CommonRail

I was able to remap my sensor,

I modified the ino to just send the 3 sensor values, nothing else.

The valve is now working as expected! ![]()