I have a Deere 7410 that I would like to install an autosteer valve into, but I’m in a little over my head. The tractor is closed center, the orbitrol is closed center dynamic load sense, non reactive, 125cc. I am in Canada. I believe the tractor is more less the same as the 6810 Mannheim tractor.

The orbitrol is buried between the muffler and cab and all 5 lines going to the orbital are hard lines. It would be difficult to make any hydraulic connections right at the orbitrol. Easy places to connect into are the power beyond plate (P, T, LS), the steer cylinders, and the LS line coming from the orbital (which runs to the rear of the tractor).

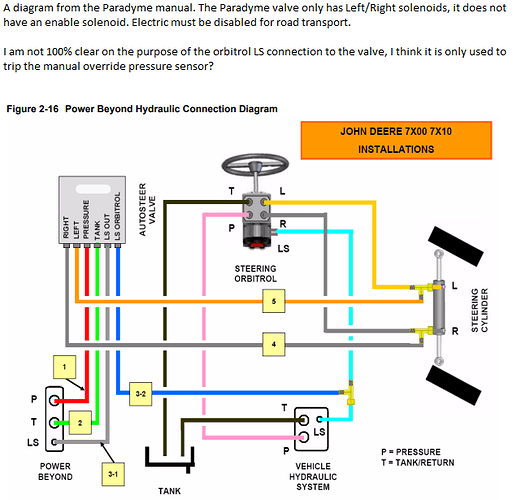

Am I correct in thinking that all I really need is a closed center load sensing valve, something in the 12 lpm range, fed from the power beyond, Tee’d into the steering cylinders? That would steer the tractor. To disable autosteer when moving the steering wheel I could either mount a steering column encoder, or Tee a pressure sensor into the orbital LS line? For safety I would kill electric power to the auto steer valve through a switch (estop switch). Maybe a 4/2 solenoid on the autosteer valve for additional safety. All these thoughs are heavily influenced by a Paradyme steer valve installation manual that I found. Please correct me if I’m wrong so far.

Where is gets confusing for me is; I’m already using the power beyond for a sprayer. The sprayer has a pressure, return, and LS connection to the power beyond plate. I also run my corn planter vacuum fan from the power beyond. Can I just directly Tee all the power beyond connections for the autosteer valve? Do I need a second power beyond plate? Can I Tee P and T and then use a shuttle valve for LS? Can I make my auto steer power beyond connections at the priority valve (I’m not sure what the three test ports are)?

What happens when I’m using all my hydraulic flow? When I raise the corn planter at the headland my planter is slow to lift and my vacuum fan speed drops some because I am using all of the available flow. If I’m doing an auto U turn at the same time, then the autosteer doesn’t get priority and turns might be difficult?

What happens to the autosteer when hydraulic pressure rises? Say I’m making an auto U turn while raising my corn planter and the corn planter reaches the top, the hydraulic pressure rises to ~2600 psi, does that cause any auto steering issues?

Any valve recomendations? I see the hydraforce is somewhat liked, but with missing pictures and diagrams it is hard to follow the conversation. I have a Parker dealer nearby that I have worked closely with on industrial hydraulic systens, anyone used a parker valve?