What would be the max pwm to get full on? What is the max overshoot reduction number?

It seems like it needs a look ahead so it starts opening valve ahead of changes in grade?

I dont know for maxPWM 255 or about 200 depending how the ino is written. 255 could trow a code on the tractor if it output under .5 or over 4.5V

Max overshot reduction is 100, 20 should be good for most applications I think. 0 is no effect.

I was thinking of a look ahead but so far I didn’t feel the need for. It’s more about delay.

Any chance you have a oscilloscope? Here are the factory PWM readings from our 8320T. The flow settings go from 0.1 to 10.0. I took these readings with an o-scope while using the factory SCV.

On float, 79% on both lines/coils

One coil at a time for each direction

0.1 34%

1.0 35%

3.0 36.7%

5.0 40%

10 58%

AoG v4 PWM settings

minPWM,100

HighSteerPWM,160

I directly controlled one SCV valve last spring with a L298N h-bridge through double throw relays. As long as I didn’t manually try to use the SCV with auto-steer engaged, the tractor was happy. Once I disabled auto-steer, the SCV had control again.

How are you interfacing with your SCV?

No i dont have oscilloscope. Using the implement interface plug referenced back in thread

I think PID would solve these issues, the D in PID is basically a look ahead (tracks whether error is increasing or decreasing over time). You have already implemented P, in your code in a slightly different way.

I think there are 2 way to solve these issues: PID ,yes, but also in OpenGrade by reading the target height a fraction of second ahead.

PID don’t know if the target height will be higher or lower on the next reading.

I have no idea how real PID works. I have just tried to implement something to fill the gap between GPS readings.

On my blade it works real good.

A bit more info, AoG v4 PWM settings

minPWM,100

HighSteerPWM,160

Couple of things could be the issue

-

Change your flow setting to the scv… this is independent in our deere machines I assume it is in cnh, so that might make it sluggish. So basically what is happening is the voltage is like moving the lever just slightly at 2.7v and almost to detent at 4.5v… but you should have a way to adjust the flow to compensate for different cylinder sizes… its kind of like a gain, but built in the tractor.

-

Increase the gain… basically just increases the multiplier…

-

Get rid of the deadband in the tractor… increase the min up and min down, they are responsible for that.

-

Max up and max down shouldn’t be over about 230 theorically, but 200 should be safe.

ChrisC So i had a question. On my Case 550 i push the 1 button on my armrest to engage automatic control. On the deere side how is auto engaged?

On deere machines two things have to happen.

- Detent (click) the scv lever forward.

- There has to be motion, found this one after touchset didn’t work sitting still, I’m guessing this is a safety if you get out of the machine to work on.

And just need to plug in with tractor off? No setting changes?

And do you know the plug style on the JD 8000 R series tractors?

And then when you move the lever it disengages?

It’s a deutsch type connector

Yes plug it in with the tractor off, if you mess up it will throw a code that has to be deleted before it will work again.

The scv acts like normal except when detented full forward. When detented it goes to automatic, everything else acts like a regular scv.

Any idea if our circa 2001 8320t would have this capability? This plug looks just like the remote valve connectors on ours.

From what I understand it should work on 00 to r series…

Basically if scv controls are electronic with a screen to control timing and flow it should work

Has anyone tried making contact with the creators of EMT? I am starting work through the flow and they have different import options, just not the one we need.

Just didn’t want to duplicate contact if someone had already started the process!

Hi, if you are referring to the EFT software I have not contacted anyone because I do not speak English and I would have difficulty making myself understood, I would be grateful if you contact them, greetings Emanuele

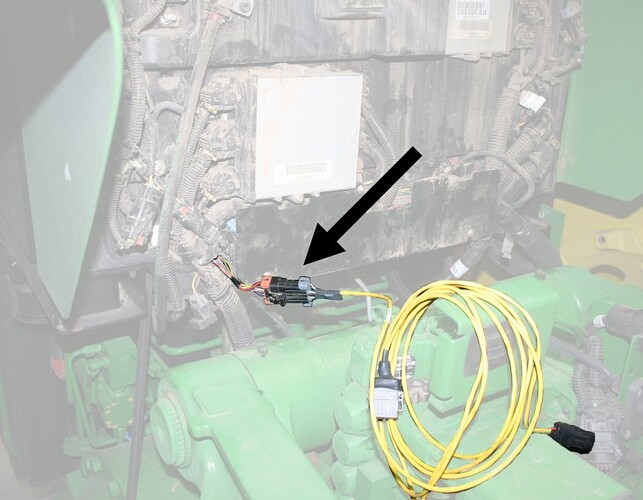

After studying the information in that link and this schematic, I realized this might be the same connector we use for depth control on our cultivator except in our instance it’s not a 2.5V centered signal, it’s a 0.5-4.5 V pot on the cultivator and the JD tractor uses SCV #1 to maintain a target voltage/depth. For example, we set a depth of 3.1 (not sure what voltage that translates to), after we press the down detent it lowers and raises the cultivator to maintain a certain feedback voltage from the pot/sensor. When we click the up detent, it raises the cultivator until it reaches 0 height. The connector we use for this is behind the rear cab external panel as shown here.

So is there one connector for SCV #1 and another for SCV #3? Is there a different schematic for this touchset(?) depth control we use? I’m curious what the different Option Pin configurations are?

The way I have it hooked up is as scv1 only.

To control both at the same time you hook up C for scv1 and D for scv2 to a control voltage instead of ground.

It appears you can set any level as the touchset target

Just a guess but I’d say it defaults to 2.5v and can be set from there