might thist fit on Fendt GT 275 from the 1980ies (no LS) as well?

Pretty sure it does. Just look out for the “OC valve”. Details are in the wiki Steering with Baraki hydraulic block | AgOpenGPS Documentation

So probably for my 2008 6530 premium autopower as well?

It was ordered by factory options with larger Pump (variable displacement, quite sure) and “power beyond” (for sure).

Sufficient oil flow, no need to care for prioritiy, so I might feed it from power beyond?

The orbitrol is hard to access, and I’d prefer an easy removal, just in case I have to get a new “TÜV”-sticker…

According to JD part list, there are only 2 hoses from pump/back to orbitrol, no LS there. Does this change the image?

But where to put the pressure sensor, then?

And in the part list, I also see that JD connects their own Autosteer by tee to the A-B -cylinder pipes. I’d really like to do it the same way, as given here

instead of locking the orbitrol off the cylinders when AOG is active (no matter whether correctly or not)

OK with that?

Of course, best thing would be if we could manage to get our AOG steerings legally certified (“Einzelabnahme” in Germany by TÜV or one of it’s bretheren)

Did anybody already try / plan / succeed in this?

Dared to necromance an old thread on that issue, instead of clobbering this already overcrowded one here

JD parts list is not that accurate here. The LS line to orbitrol is always missing in the schematic. But your 6530 Premium might have LS on the orbitrol. Made quite a few John Deere 6x30s.

You can install the valve under the right stairs like JD does it with there factory valve. All hoses are there, except LS. Then you have to get LS from the back, like you said there is not much space at the orbitrol.

Otherwise you can mount the valve in the back, there is P, T and LS. So you have to extend the steering hoses to there.

Did both, don’t know whats better/easier.

I don’t know anybody got a German TÜV on that.

Could you supply proof for this conjecture, e.g. by a datasheet or confirmation by the manufacturer of the valves?

Might greatly enhance the chance to acquire road certification, even in Germany …

Do you have access to genuine schematics for hydraulics (and may be even CAN … ![]() ) for the 6530 premium (and bretheren, of course)?

) for the 6530 premium (and bretheren, of course)?

in particular:

-

(how) can I access orbitrol LS for attaching the pressure sensor somewhere in the back, near the pump?

-

you say that P an T are available near the right stairs. How can I find them there?

-

(sorry for drifting slightly off topic in this thread

)

)

for additonal functions (implement control, rate control, tool engagement…) I’d like to try some reverse engineering of the CAN communication - e.g. to get my hands on the SCVs. Would really be great to have at least some plans of which box is located where and where to look for the CAN cabling. -

of course, any CAN already documented would be even better

-

And there are rumours that JD is one of the least cooperative manufacturerers for tractor hacking

. So If sbd knows that reverse engineering is beyond hope (e.g. if boxes use encrypted / signed modes of communication), I’d be glad to be warned from spoiling time for hopeless endeavour…

. So If sbd knows that reverse engineering is beyond hope (e.g. if boxes use encrypted / signed modes of communication), I’d be glad to be warned from spoiling time for hopeless endeavour…

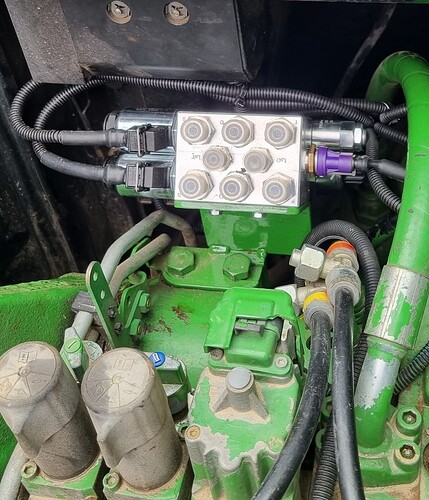

Hello, I did a 6830 Premium 2011, you can see the photos in this thread, post 376-380

For the piping, I followed the JD Autotrac installation manual.

To bypass P and LS, I went to the priority 1 valve located on the rear left side, under the cab. It’s a bit laborious, but it’s possible to connect T-connectors

PFP20686_19 Autotrac 6030.pdf (2,7 MB)

If your using the power beyond connectors and Tee into steering lines,

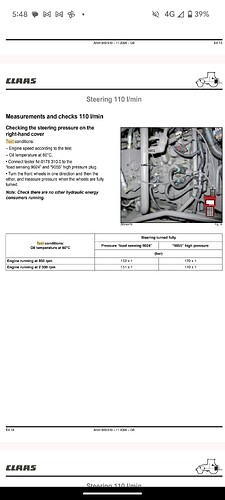

There should be a test/diagnostic port for the steering LS line, where you could connect a pressure sensor.

In the diagram below which is for a Class Arion you can see port 9024 is to measure the steering LS pressure, must be a similar thing for JD.

Great thanks!

Don’t know how the posts ara counted here, but I think these are the Photos yo refer to?

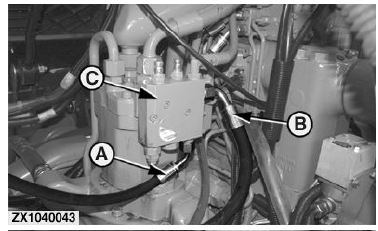

This is the corresponding image from the JD autotrac manual (they tilted the cab)

(A) is orbitrol LS.

So I hope when I just want to attach the sensor there, I can do so with the cab down.

Hello, I made it with the cab down, the most difficult thing was to screw original P hose, it is very rigid.

At the P outlet of the priority valve, you put a T fitting that feeds the original P hose and the new P hose that goes to the Baraki Valve. The original LS hose has to be taken to the LS outlet of the Baraki valve with a supplement and make a new hose to connect the LS outlet of the priority valve to the LS inlet of the Baraki valve.