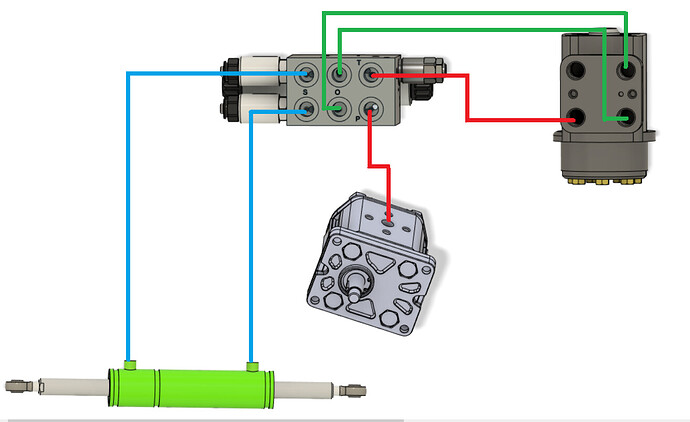

Your orbitrol looks like open center?!

Am I right?

Yes it is OC, with only 4 ports.

EDIT:

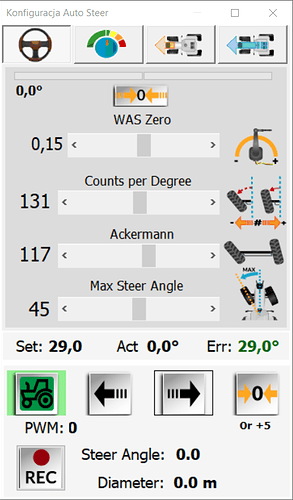

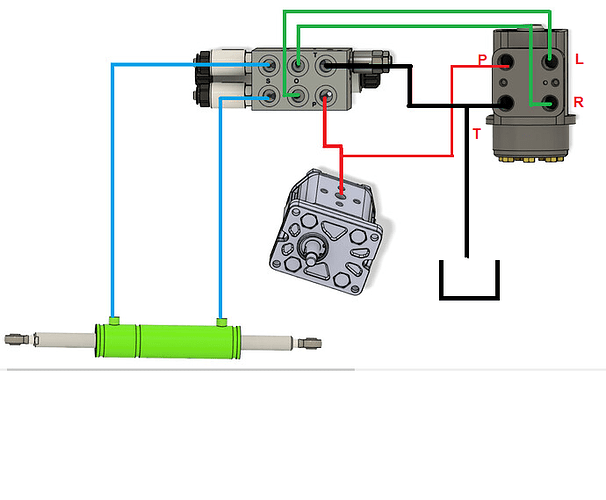

I found out that pictogram is on the bottom, it is this type. So I guess that metal pipe is T and bottom is P. Idk why it is rotated 90°.

And TeddyStamford, yes it answers my question about orientation of valve block so there is only 3. question to answer, thanks.

It is very easy! The most important thing is not to confuse the T and P ports, reverse connection may damage the hydraulic pump, so check carefully if it is correct.

The overflow valve you have marked (2) can be adjusted as follows:

After connecting everything, turn on the manual mode and “command” turn the wheels to the maximum angle, the PWM sent to the valve should then be above 100. Then, with the engine running, tighten the overflow valve until the wheels start to turn and pull to the set angle. Be careful not to be between the wheel and the body of the tractor, as there is a risk of crushing.

If you do that in an OC system, then almost all the oil will go through orbitrol even when autosteer is on.

I say almost , because there is some pressure left from the flow , and perhaps if oil is also used in gearbox for hi/lo.

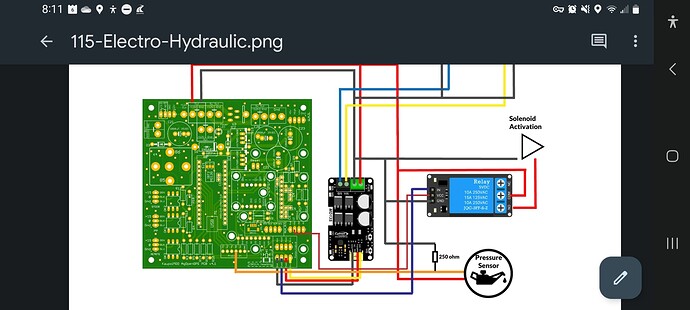

Are diodes installed on the coils? Can the Cytron handle the load?

Srry my bad!!

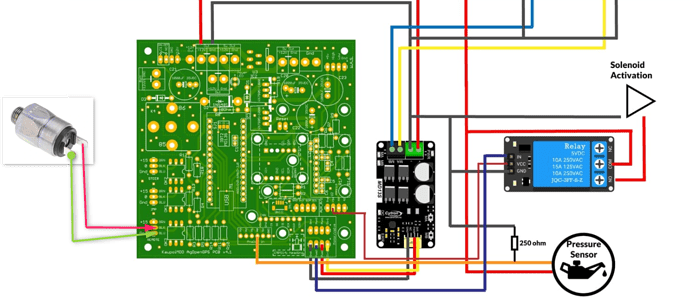

The coils are without diodes, the citron does not require additional protection, I have never had a case of it being damaged. The coils of the 3/2 valves must be protected with a schotky diode, currently released all-in-may 1 boards have a built-in needed diode. If anyone wants, I can also add diodes to the solenoid plugs.

By tightening the sensor 3 adjustment screw clockwise, you increase the force required to disconnect the A.S. Run everything and try it, if AGO disconnects randomly, tighten the screw e.g. by 1 turn and check if it is good.

Can you add some schematic of it? Thanks.

Edit: and maybe parrameters of diode.

For example, it can be any other universal you have at hand, from 1 ampere and voltage above 60V

What board are you using?

I use Kaupoi PCB

The Kaupoi board has a mosfet designed to control the shutoff valve, it works fine even unprotected by a diode.

I use a 5V Relais with signal from PWM2 Pin for valve activation, because its cheaper than the mosfet

How does disengage act for the rest of you? Can you just grab the wheel and steer? It’s on a JD 7520 with closed center Ls hydraulics.

That’s how it should work. No force should be required. If it doesn’t work well, we’ll find out why. Describe exactly what your installation looks like, what PCB and software you are using