Evening all

My PCB 4.1 (Micros) arrived, so time to test them. Thought I’d document the process just in case it helps anyone.

I got lucky and JLC assembled all - I did remove the headers for Teensy and BNO/IMU from the build as they weren’t too great on my assembled PCBv2.4 and I didn’t want that hassle again.

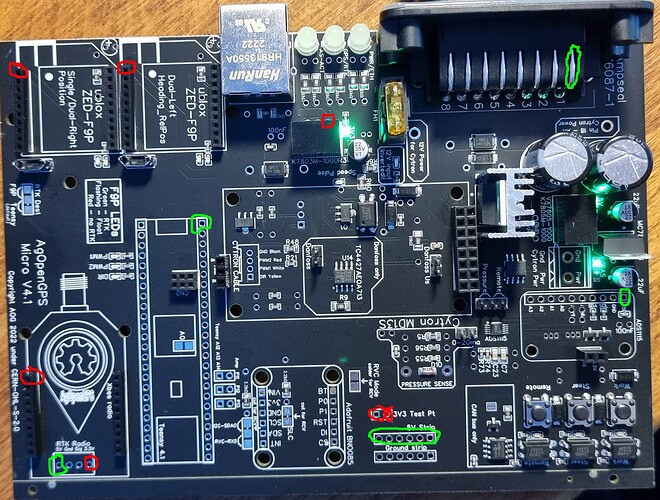

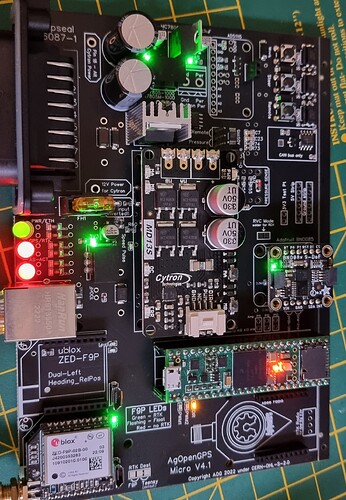

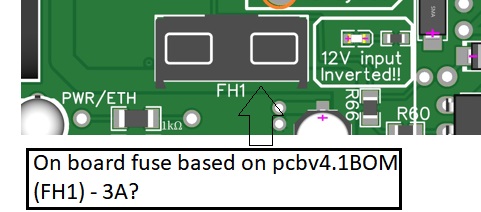

First, a visual check to make sure everything looked OK, no damage etc. There were no apparent faults and the all-important voltage regulators appeared to be the right way round, so I connected it to my test bed, inserted a 5A fuse (smallest I could find) and powered up gently. Straight out of the box, this is what I got:

As you can see, there are a couple of LEDs lit up already. The green and red annotations are where I put my test probes to confirm the all-important voltages going to the expensive components. RED is 3.3V, GREEN is 5V. As you can see, the hardware team did a great job and also put some handy probe points in, and LEDs to show all was well. But, you can never check enough - especially when F9P is so expensive. So before you connect anything, sort that out.

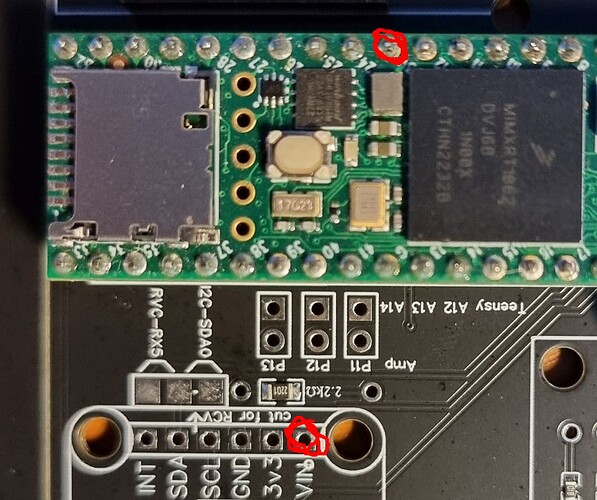

All appeared well, and so I soldered my headers for Teensy and IMU on - all good. I knew only 5V was going to the Teensy, instead of anything more accidentally-serious, so I was confident to plug that in.

Now, with Teensy there, it supplies the IMU with 3.3V, so I checked I now had only 3.3V going to the IMU input from Teensy (in red). All good. Time for the IMU.

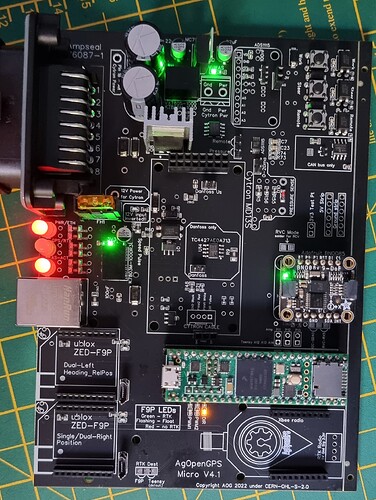

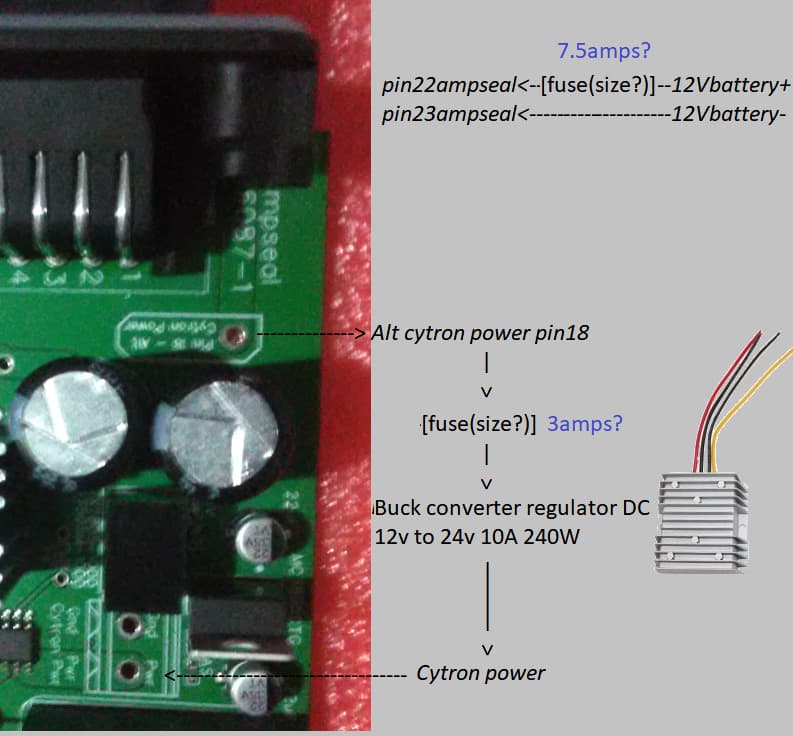

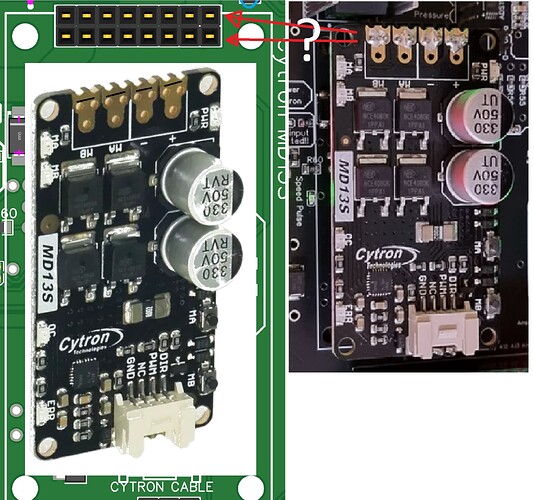

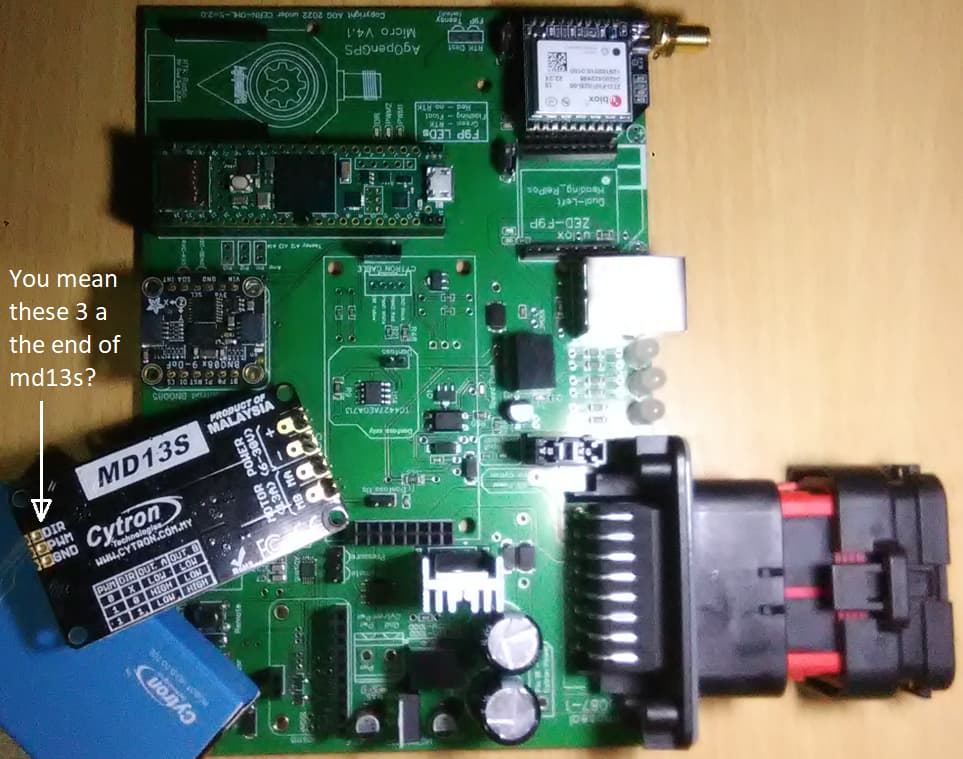

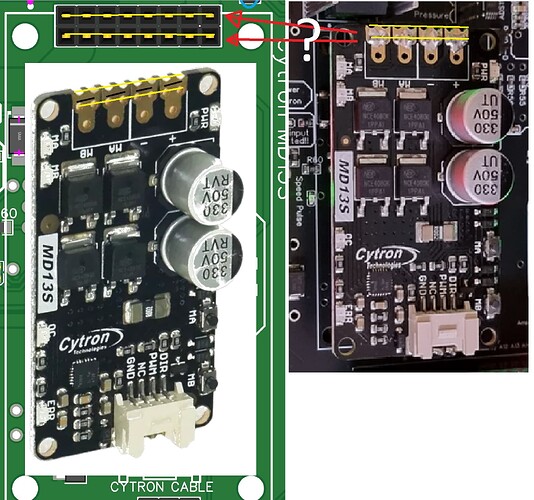

Teensy lit up the IMU, so progress. Now, add the Cytron. This was low risk as at the moment, I don’t have an input selected for it (I’ll use the standard 12V for this as that suits my use case):

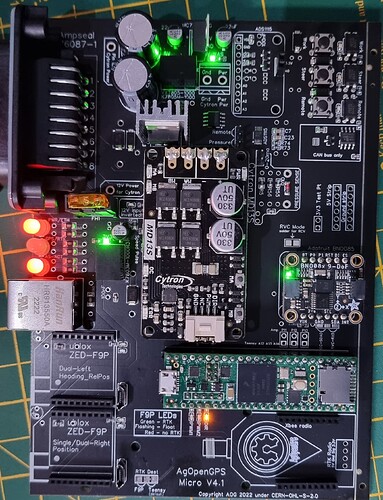

And with that on, I added my F9P, connected ethernet up and … we’re good (photo taken just as the board achieved an RTK fix) !