You mentioned valve polarity earlier, it seams as though my valve is functioning backward, but when I reverse the MA/MB connection from the cytron it doesn’t appear to change anything. Is there some other way to reverse polarity?

A solenoid can’t really function backwards.

I’m 90% sure you have a solenoid valve controlling oil flow.

All it does it open and close really fast to allow oil to flow.

The cytron is varying the time it’s open and closed to allow more or less oil through. (Many times per second)

Polarity is important on a motorized butterfly value because the cyteon opens or closes it by varying amounts to control the flow - your valve doesn’t have varying positions like this.

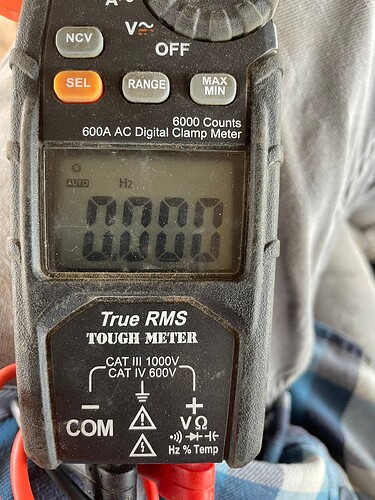

The voltage reading from your flow meter, does it change with flow? Higher volts with more flow, lower volts with less?

Checked out your multi meter. It should work. Did you have the HZ range set on auto ?

Might be time to start putting photos up of your setup. It’s going to be something simple but it takes a while to get to the bottom of it.

You really need to get the system working one thing at a time.

Get the flow meter working, then focus on the solenoid valve, then bring it all together.

Based on what you’ve said it sounds like I have a standard valve.

As far as the flowmeter, the voltage stays between 2.6-.27 volts at higher flow rate. If I use a hand valve to turn it down to a trickle the voltage starts jumping between a much higher range 1.8 to 3.4 volts.

I agree. I was thinking the flowmeter should be first point of attack. This really has me frustrated and I would be lost without all the support from this discourse.

I am using the following pump/valve combo:

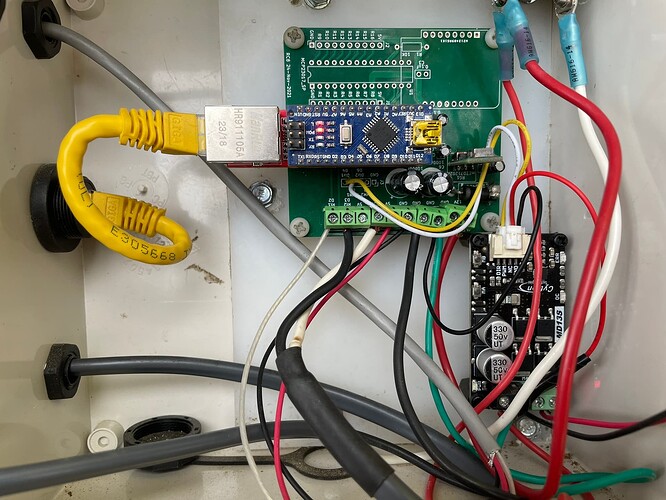

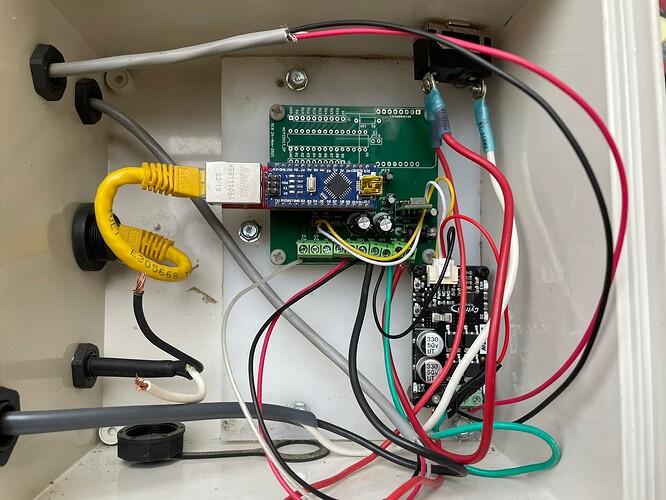

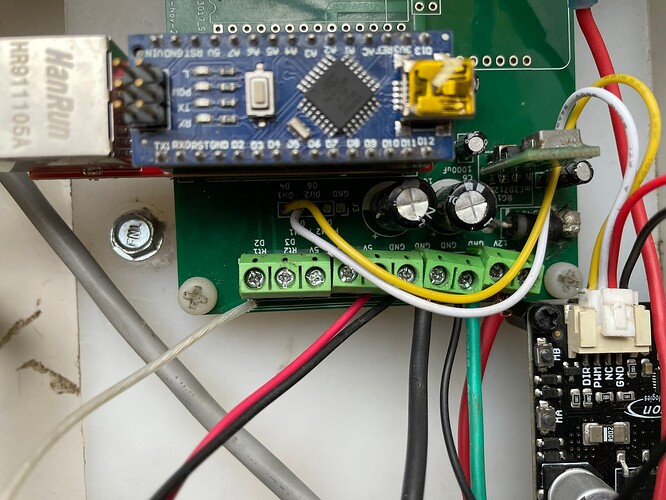

Here are some photos, if I need to post a picture of something else please let me know:

Straight away I can see some issues with the wiring to the cytron.

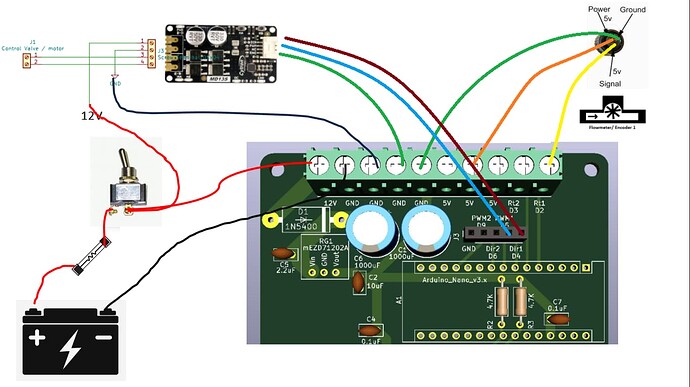

You don’t need direction connected for that solenoid valve. It just needs ground and a PWM.

You also have something connected to both RT1 and RT2 but as you only have one flow meter I can’t understand what the second connection is doing there.

You need to revisit the wiring diagrams from the RC GitHub and check you have the wiring correct. Maybe draw a wiring diagram on the board photo SK21 posted in reply 4 and then post it here so we can follow it end to end.

I would pull the flow meter off the board and get it working independently with a 5V power supply and then once you have a good pulse reading on the multi meter that checks out with the 142 pulse per gallon cal factor then carry on from there.

You will likely damage something if you test things while it’s all wired up, and maybe wrongly wired at that.

As Hman said a circuit diagram would be very helpful. Is the valve just before the flow meter an on/off valve?

Have you done the 3 steps in these videos?

UAN.zip (2.1 KB)

Try this setup file for the rate app. Unzip and use menu ‘Open’ .

I will get one drawn as soon as I can. It is a on off switch wired to the cab, mostly there to prevent product from just running out when the system is off.

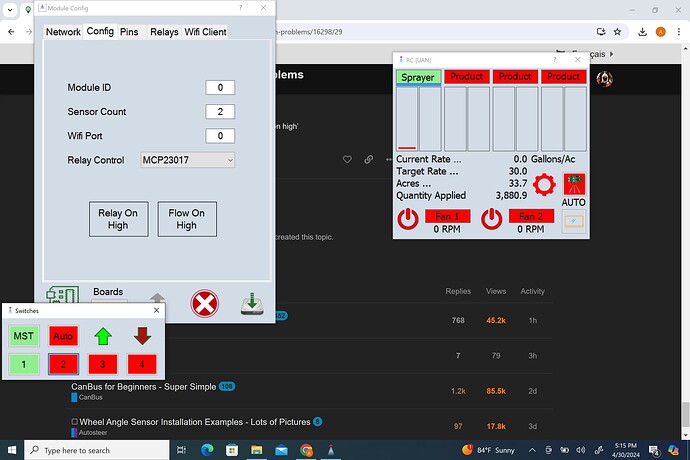

I have followed the videos, and I am connecting with the module.

I loaded the config file, the master and section switches are staying green when I touch them. However the valve seems to be working in reverse. When hydraulics are activated the pump pressures up, then when you switch on the master it stops the flow.

In module config you can switch flow direction. ‘Flow on high’

For some reason this doesn’t seem to change anything. I have pressure when the master is red and doesn’t when it is green.

Here is what happens when I attempt to calibrate. It does this until I hit the stop button.

Did you try it when the flow button was both green and not green? Did you save after changing and then send to the module?

I did, I kept expecting it to change when I het the save changes button.

Until you get it wired properly you are wasting time trying to calibrate anything.

Going by the photos there’s multiple errors in your wiring so it’s highly unlikely you will get favorable calibrations until this is fixed

Okay, I want to do this the right way. Sorry I am a little slow It’s been full swing into farm season.

I haven’t gotten around to it, but tomorrow I am going to test the flow meter independently for pulses while connected to my bench supply.

Here is my circuit diagram below. I do intend to remove the wire from dir1 to cytron dir as you have advised me. I’ve used the diagram from the post but just added my everything else.

Looking good from a wiring point of view now.

Now you just need to ensure the flow meter is working.

Also checking your pump tech data again, have you checked it’s not in manual override mode on the hydraulic spool?

Also, if it’s not much work, let us know how the shut off motorized valve and bypass valve are wired in. The Teejet ones.

I will let you know the results from my flow meter testing

I have, I was hoping this would be my problem, but sadly it’s not.

The bypass valve is a manual twist style. The motorized valve is a three wire. It has 12v and ground run straight from the battery and then other wire is run through a toggle switch in the cab.

So the 3 wire valve is powered full time, and the toggle switch alternates its position to either fully open or fully closed and nothing in between?

Long term it sounds like this valve should be wired into the master switch function so it’s not an additional manual task to play tricks on you.

Your manual bypass valve would be worth cracking open during testing. You mentioned the pump speed being so high the pressure was concerning you. Open the bypass back to the tank a bit as a safety until you get it working.

Yep, that’s how it works. I would definitely like to wire that in later, but until get this system working I have to leave it there to use the rig manually.

I will crack the bypass when I do try to calibrate.

However on that , I tested the Flowmeter today hooked to my bench supply @ about 5.4v in to the Flowmeter. I had several spray tips off, based on gallons used the pump was putting out close to 16 gmp, more than enough to generate pulses. I never got any Hz from ground to signal but did read a much more steady 3.4-3.5 volts.

I also noticed that even with the flow meter unplugged, the RC app still show product being discharged.

Do I possibly have a ground issue?

Did you try swapping the multi meter around to measure signal to positive?

Have you also confirmed this flow meter will work with 5 volts via a data sheet or another user? Some do, some need 12 v and then can’t be connected straight to the board.

I did not try measuring signal to hot, but according to Raven tech support you short signal to ground to simulate a pulse. Here is the test Raven emailed me:

Thank you for your recent communication with Raven Technical Service. For your reference, Case Number 00356986 has been assigned to this issue. Please include this number in any future communications regarding this case.

Regarding our Communication

- Enter a Meter Cal of 1 if doing liquid, or a Density of 1 and a Spreader Constant of 0 if doing granular.

- Place the system in Manual if using an SCS console.

- Zero out the total volume on the console.

- Turn at least one boom section to the “ON” position as well as the master switch. • Try multiple boom switches in case there is a faulty hardware switch connection.

- With a small jumper wire (or paper clip), short between Ground and Signal with a “short-no short” motion. Each time a contact is made, the total volume should increase by increments of 1 or more. • If the total volume does not increase, remove the section of cable and repeat the test at the next connector toward the console. Replace defective cable as required and recheck. • If all cable tests pass then there is a problem with the flow meter / encoder. Replace the flow meter / encoder. When finished, re-enter the correct Meter Cal or Density and Spreader Constant.

If you need any further assistance, your local Raven Dealer/Distributor is just a call or a click away!

The information provided is relevant to this case and may not apply to other similar situations.

Thanks & Regards,

Raven Technical Service

I would love to try this but my RC app always shows a constant flow, even with flowmeter unplugged.