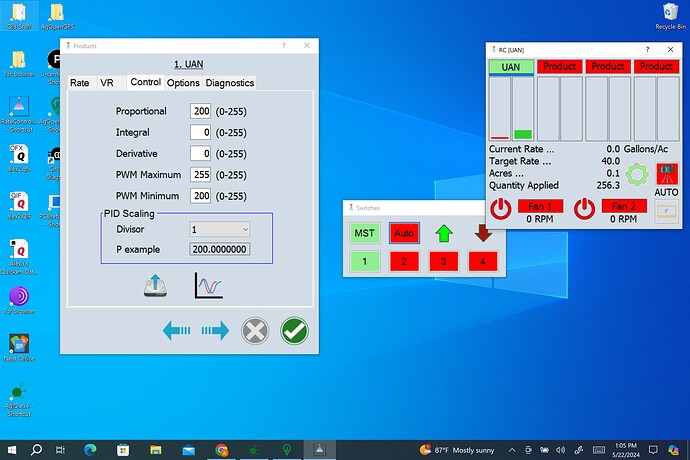

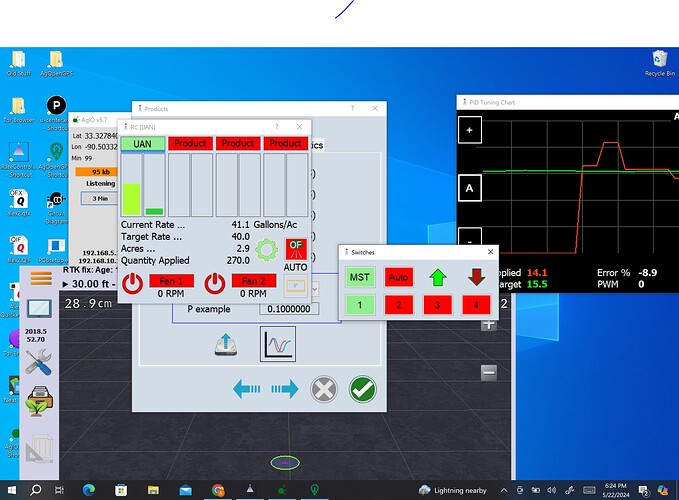

If it is a valve controlling a motor the control type should be standard valve. What are the control settings for the valve? If MA or MB light up but the valve doesn’t move the settings may be too low. Start with the Divisor at 1, PWM Max at 255, I at 0 and D at 0. Adjust PWM Minimum and/or P up until the valve moves.

And if you hit the MA button on the cytron do you get full noise to your liquid pump? Presumably solenoid valve open?

I’ve tried it as high as this to no avail. I can hit the up rate button (green arrow) the valve will open momentarily. This is all with it set to standard valve. When I run it as combo close and activate auto it attempts to correct but just just around everywhere.

Yes, it immediately opens all the way when I hit the MA button.

It jumps from 255 to 0 to -255.

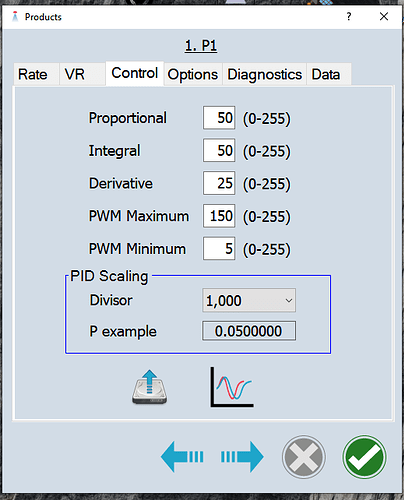

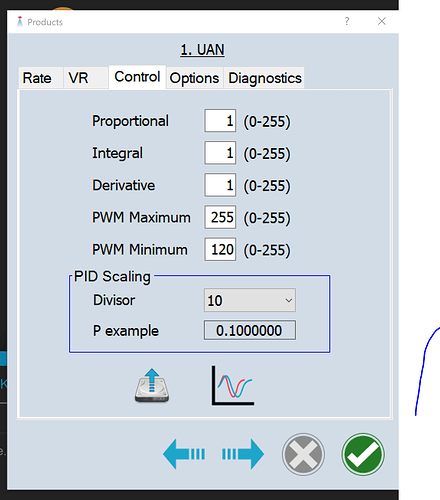

It may be overshooting too high and too low. Start with P at 1. Adjust PWM minimum and P gradually until the valve starts to move.

There’s something wrong with the settings if it goes to -255

I don’t know enough about the code in the rate control app but It should only be trying to control between 0 and 255 as the valve is Normally closed. Between 0 and -255 the command will have the exact same action on the valve as 0 to 255, so in effect the rate app is trying to slow the flow by sending a - something pwm but if you had DIR connected this would actually open the solenoid just the same as a +pwm.

Assuming you don’t have DIR connected any more it’s realistically probably just meaning the rate control app spends a lot of time sending a message that never gets through to the valve and is limiting how accurate it can ever work

So I was able to get it to stay close to rate at lower speeds with these settings.

It also calibrated fairly quickly. I’m still getting a little over/under compensation while chasing the rate so I think I am almost there. I will continue to fine tune with the controls.

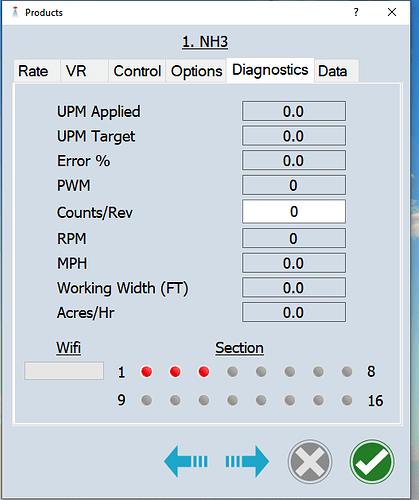

So I can only get the valve to behave this way when: AUTO is on and I am within a field boundary and moving. Why is this?

I can see correct target UPM for my speed but the valve stays closed. When in manual, both when run as standard valve or combo close. The only time the valve will open is when in combo close and all switches are off OR in combo close or standard valve with MST, section and AUTO on.

When I attempt to run without auto

In auto mode with the tractor stopped there is no work being done so the rate is off. Outside of the boundary AOG turns sections off.

In manual mode with sections and master on, did you try the up/down arrows to adjust rate?

The chart on the Control page may help with tuning.

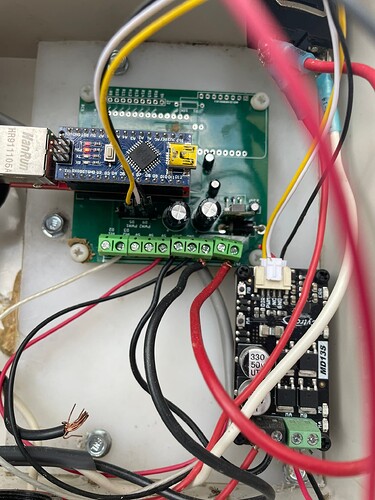

I actually had a voltage regulator go bad on the last board so I built another. This time I soldered female header pins and used a grover/dupont type connector so I can move them around. I have DIR plugged in this go 'round.

It will never work.

-255 will give you full flow just the same as +255.

But the rate controller doesn’t know that, so it will chase itself round in circles for ever.

Write yourself (or get AI to write you) a very basic sketch using the cytron motor driver library and play with it a little until you understand how you components work, and how they respond to certain commands.

In manual mode the up/down arrows start at pwm minimum. If the button is held pwm will increase 5% every 500 ms for a total of 3 times. If you watch the pwm sent as you hold the button it should increase and control the valve quicker. Does the valve stay in position after the button is released? If the pwm minimum is too low the manual adjust may not work.

It’s a normally closed solenoid valve.

It only has 2 positions, open and closed. So it can’t really “stay” in any position other than closed or open (assuming if given straight 12v dc it will just stay in the open position )

About as close to what your asking is that it could oscillate at a constant rate if given a constant PWM signal.

Ok, I see. How should the pump be controlled? Just treat it as a motor to vary the opening of the valve and speed of the pump?

Yes I think that’s the best solution. Single direction motor, 0-255 only. Noting that it may not oscillate until a way off zero pwm and may need a minimum setting still.

Is there a way to do within the settings, or could I remove the DIR input and run it as a motor?

The same place you select valve or combo close should also have a motor option. DIR wiring can stay. Just not needed and won’t do anything under “motor”

Gotcha.

I had my AOG out of the tractor so I used a simulated speed. After some adjustment under control tab it seemed to function quite well as a motor. It would adjust the rate when I changed the simulated speed.

Today I am running AOG and the Mater is kicking out after 3 seconds, with or without auto. No matter what the master kicks out. If I go back to simulated speed to it works fine. Is there a setting in AOG i need to change? What causes the master to kick out?