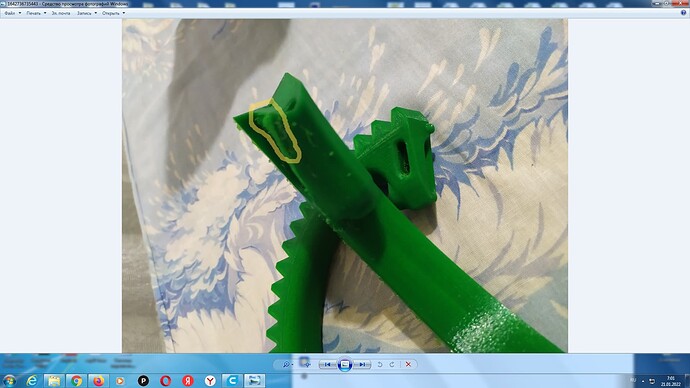

Hello. I’m trying to print gears. I used the files PotatoFarmer. For which many thanks to him. It seems to be not bad, although I print for the first time. But there are some problems. When I start printing the gear sector, the border, so that the part is held tighter, is not immediately printed on one edge during printing. It is printed only after several layers. But then she does not stick to the table and lifts herself up, since nothing is holding her back. Maybe I missed something in the settings, that I can do it this way.

Problem with marked place