I found on my printer that there was to much friction from the spool holder when i was trying to print the TPU. The Spool needs to run very freely on the holder. at least that has been my experience.

I would recommend something like this. You should be able to find something that fits your printer on https://www.printables.com/ or https://www.thingiverse.com/

I also have a sv06. Both times I have tried the small gear with tpu it fails about 3/4 of the way through. For me it’s not resistance of the spool, but rather it just stops feeding through the heat break and nozzle and curls up a pile in the drive gears. I tried zero retraction thinking it might have been pulling back too far and cooling, but the result was the same. The second time I caught it right after it happened and pulled out the twist, pushing the filament through the nozzle by hand was easy, I’m printing very slow, 30 I think. I’m not really sure what’s wrong. Cheap tpu seems to not offer many specs so I am planning to try a different brand which reviews say is a bit harder and easier to print. My other thought is the printer is just pushing more material than it should but I don’t know where to begin adjusting that.

i had the same thing happen to me and it got better when i installed the upgraded spool holder. also turn off retraction. What temp are you using and what Filament do you have?

I made a spool holder with bearings that has nearly no friction, anticipating friction problems. As of yet I’ve had no problems with the filament bunching up between the gears and the bowden tube (and I’m using a long tube since it’s not direct drive). I did have to print a new extruder mount to make sure the clearance between the gears and the tube guide were very tight. I would think the SV06’s extruder would already be tight enough.

It’s worth doing a thorough clean of your nozzle and inside the hot end. I had troubles when I switched filament with the nozzle and hot end not being completely clean.

I print TPU at 240C. I’ve been using 50% part cooling fan but I haven’t printed something quite as big as the gear, so I don’t know if that’s optimal or not.

TPU is much easier to print with a direct drive. With my printer it also likes printing about 10% slower than petg.

Still trying to wear out the gears. They do polish up a bit.

The SV06 they are struggling with is direct drive.

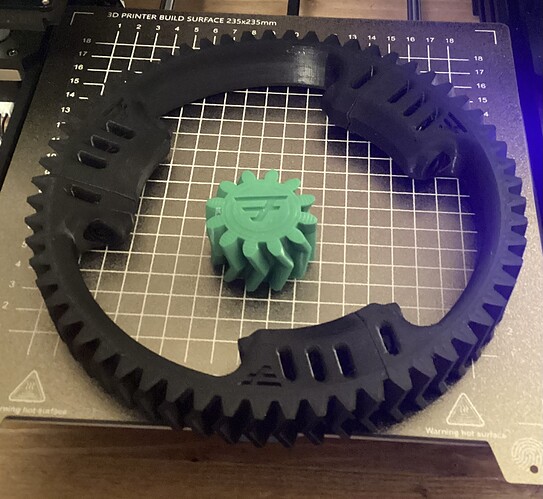

Just finished the gears on my SV06. I think they look awesome. Excited to get them installed. For the TPU I was printing at 230C at a speed of 30 with retractions off as you guys had suggested above. I was also using the same spool holder as @mkoenig. Big thanks to him for advice on printers/printing and helping a newbie get started with it, as well as to @PotatoFarmer for a very cool solution!

A question. Can you use tpu in a small room. Most say its toxic. And my work bench is next to my printer. Using Petg now not smelly or toxic… they say

Your TPU small gear is way smoother looking than mine. I am using the same settings as you have mentioned. At least with the latest brand I was able to complete an entire part.

What slicer are you using and where did you get the SV06 profile from?

I have been printing TPU in my office next to my computer. Maybe my nose and brain cells are already all gone but I can’t smell anything coming off of TPU. A quick google search claims that TPU generally does not seem to emit very many harmful fumes.

I am using Sovol3d Cura 1.5.4 and the profile is from Potatofarmer’s instructions. (.2mm layer height, 3mm wall thickness, 2mm top/bottom thickness, 60% infill tri-hexagon) Is that the info you were looking for?

That was my next question, thanks. Looks like I saved just a few dollars too many on mine. I like how that roll has approximations of how much is left on the side as well. Nice little touch, especially for someone as new to this as me.

TPU is not bad for fumes, tried TPE and was gassed out instantly wow did that filament reek.

For sure! This stuff wasn’t too bad, I think around $25 US off Amazon. I also had the bed set to 60C and it stuck to the bed REALLY good. I had a difficult time removing it but finally managed to without damaging the bed. I’m not sure if lowering that temp would help at all or if someone else has some other tricks for removing TPU from the bed.

I just finished printing the quick tach parts and they aren’t fitting together. I guess expected to do a little filing but not as much as I’ve had to do to get them together. Is it likely I messed up something in the cura profile or is there anything I can adjust for future prints to ensure a better fit?

What sort of print quality are you getting? There are literally dozens of things that can cause dimensional issues on 3d prints.

I just printed mine as well. I started with v1.3 of the tension brace. It just wouldn’t go together. Then I printed the loose tension brace and it’s extremely tight but I got them together! I might sand/ file just a little bit of it down. I’m gathering that maybe I should reprint a chep cube and measure with a digital caliper and get settings bang on. I don’t have one yet, that’s why I haven’t checked. But for me, the loose dovetail joint fits together now so I’m not too concerned.

Mine also didn’t fit without filing.

However, printing the segmented gear is giving us a headache. It becomes unstuck from the plate after ten hours of printing.

Would anyone here be willing to sell me a segmented large gear? I’m in Québec, Canada.