That makes sense. I have been happy with the quality so far but I am still wrapping my head around everything. I had forgotten all about the loose dovetail version of the brace so my next move might be to try that out.

Thank you! Completely forgot about the loose dovetail version. I’ll give that a go.

My problem with lifting was a couple things.

First off, my filament was wet, had to dry it. Also wasn’t close enough to the bed.

- make sure first layer is extruding at 140% line width, thicker line adhears to bed better

-also if printing at 0.2 layer height, increase first layer to 0.28. It helps with uneven beds, if there’s a low spot it’ll help fill it in better

-dry your filament whether you think it needs it or not

-adjust your z offset so first layer looks completely flat and even. If lines are not touching, bed is too far away move it closer, I’d lines are “streaky”, you’re too close

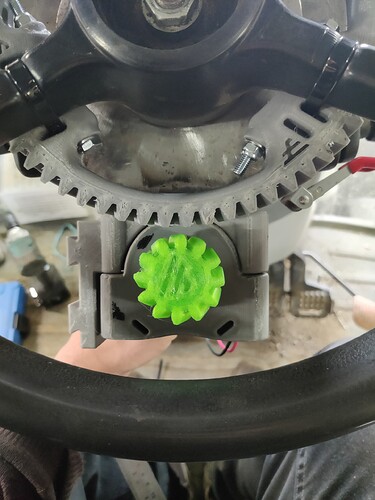

Loose dovetail fits great!

I used a 0.8 nozzle (still 7,5 hours to print it)

We decided NOT to use the segmented version. Mounting the motor will likely require you to remove the steering wheel. Putting together the segments caused it to stuck at those places… 1 piece solves this.

We used the MFA 986 motor (12V does very well on 6+ tractors with this gear set)

big gear PLA small gear PETG → no noise, easy and fast to print. Small Gear we did 100% infill.

For the holder we went with All the 3D models of entropiemaximun・Cults

And designed our own small gear + some plastic to cover it up.

AOG Small Gear for MFA986 v1.zip (1.4 MB) Licensed under WTFPL ![]()

Hi everyone. I printed the segemented gear and have realised I can’t get the motor near it. Is there anyway of making the circumference larger?

Hi ben-brad, I have the same problem on an older Allis. Has anyone created an elarged large gear? Could we get the CAD files for the segmented large gear, and we can then updated it for a larger circumference?

I have also run into this problem today on a Claas Arion. I agree it would be useful to have the CAD files as well. For me scaling up the 2 gears by approximately 12% would solve this.

If you tell me what gear circle diameters you need, I can modify @potatofarmer’s STLs to any custom size with FreeCAD. Or of course if he sees this he can do it too. Or give me the mm between the two gears and I can give it a try.

I am currently swamped with the AOG PoE Ace build, new job and the new kid. Have fun.

Never thought these gears would get this popular. The magic power of zip ties.

Is it born already? If so hope all is well and congrats.

Thanks for the offer @torriem but I have had a go in Fusion 360 this morning. I think I have managed so I will let you know how I get on… I might take you up on your offer yet!

It looks like the standard design is ~120mm from the centre of the big gear to the centre of the small gear. I needed a distance of more like 135mm so I have scaled up by 12.5%. I then had to remodel the socket for the motor shaft. Files are attached in case they help anyone else @ben-brad @davewd45 but use at your own risk, I have not printed yet!

AOG universal fit gear system scaled 1.125.zip (4.8 MB)

Thank you @PotatoFarmer for the original design, @torriem for the offer to update the files, and @HNorthern for the new files. I’ll take a look at the larger gear only to see if it fits my needs.

There are some steering cogs specific to the Claas steering wheels, moulded perfectly to it.

Will find a link, they are also a big diameter than Potato Farmers and I think not as thick.

@HNorthern here you go:

https://drive.google.com/drive/folders/12z2gxmFyJBLBNhLvWaNDLJYHxIeLW-OM?usp=share_link

Yes he is out and about! First couple days and already complains about the weather, a natural!

This gear works nice ![]()

Started with a clutch and gears from this link. But the smal plastic gear did not hold up.

The solution a combination of the clutch and this gear

Do you have the files for this steering gear and the spoke holders?? Was planning something simulair but have not the right tools.

So please share.

Spoke holders are from the first link in the post. The first plan was to use ziptie like others do. But after i had used the spoke holders from the first solution i went back to plan with them. I just used a 5mm drill in 6 of the ziptie slots (the distance between them fitted perfect for the spoke holder i had laying).

So you did not edit the gear itself?