No, just with a drill after it was printed

i see you use the complete gear not the 3 segments. Am i right?

Yes, the complete gear

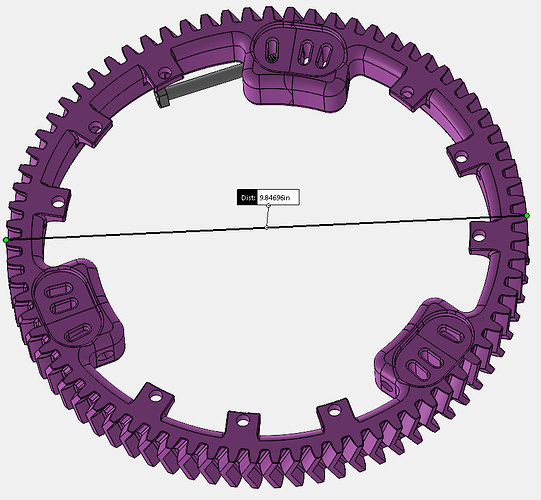

We have created a segmented gear modeled from PotatoFarmers, but with the ability to easily increase the diameter while maintaining the same teeth, so it’s compatible with the other gears. Have also added additional ziptie holes for 3 spoke steering wheels where the spokes are not consistently placed. @PotatoFarmer do you have the pressure angle and module specs for the teeth on your gears? I want to ensure it is compatible with other gears then we can post the files to the group. Our gear works with your motor gear but I feel it could mesh just a bit better.

Unfortunately have no technical information on these gears, drew them to learn how to use Fusion 360 in 3D back in 2021.

Just kept drawing with a general Idea until it fit on the fit on the machines I operate, and shared the .stl’s as is.

From what I can see, the gears are using the standard pressure angle of 20 degrees, and the helix angle is also 20 degrees. When I generate gears with that spec and overlay them on the imported STL, the profile matches perfectly.

And the module of the gears is 3.25. To scale up the gears you’d change the module, since module is the ratio of the number of teeth to the diameter.

Do you have picture for your system?

Here’s a picture of my setup. It’s my very first prototype. I’m not happy about the chunk of plywood, but with the steep angle of the steering wheel spokes, and the fact that they are not spaced evenly, I am not able to attach the gear via. the famous zip tie method. I think i’ll try printing some brackets that go over the spokes to attach the gear. Thanks to torriem, for additional specs on the gear, we were able to design a larger gear that works with the existing small motor gear. I can provide the files for the large gear if anyone wants it.

Looks really good, dont feel bad about the plywood. If you look a the Steiger i put the other gear on there is plenty of radiator hose to shim it in place.

Old steering wheels are not the most perfectly made. Life before CAD.

We found way less issues when printing the gear from 1 single piece (if your printer can handle it…)

True but not every steering wheel comes loose with just a lil hit on it. I prefer 2 parts or 3. So easier to mount.

Near the beginning of this thread was not convinced about the 3 parters.

But I was wrong, the bolts give a ton of stiffness.

If your printer is dialled in when they mesh they are nicely one piece. Also less complication removing the wheel.

Thanks PotatoFarmer, I got a good chuckle out of your radiator hose comment.

I’ve been trying to find someone to print me the complete set of gears and motor quick tach setup. The local businesses dont seem to want to get back to me. Anyone willing to print some up and post them to southern alberta?

I would be willing to print up a set and mail it. I am in northern Alberta. Send me a pm

I’d love to have it ![]()

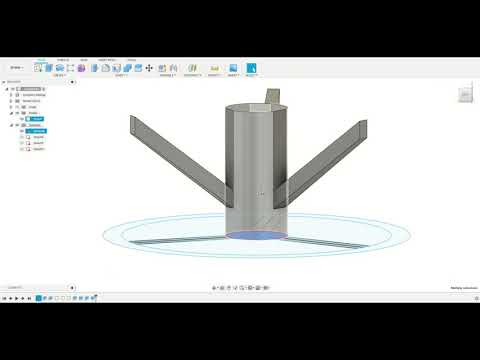

Hello, the idea of a potato farmer is great, but I don’t like fixing the rack on the clamps, I’m trying to model the steering wheels from Case magnum 7210Pro in the fusion 360 program, it’s a bit cumbersome because it has irregular shapes, there is someone in the group who copes well with the program fusion 360?

I want to make my sprocket with a cutout and top mount like in the YT video

Przesyłanie: 20230424_180107.jpg…

Przesyłanie: 20230424_180051.jpg…

Przesyłanie: 20230424_180011.jpg…

Did you try importing a photo of your steering wheel as a canvas? Thats how I made a steering gear for my Versatile and Case 9270

I must correct myself: PLA does melt in summer… oh well ![]()

I’ve had some PLA things that have done fine in the cab. I printed a cell phone holder for the sprayer with PLA and it’s been right on the side of the armrest console for four years and is just fine and is never soft even after sitting in the afternoon sun for a few hours. Then I have a little RTK radio receiver box on in a back corner of the cab that’s also doing fine. Then I made a mount with black PLA for some buttons on the armrest console and they all melted after one season. So I guess black probably melts before the other colors.

I use PETG for nearly everything I print now.