Anything PLA that I printed melted right away. I made a whole bunch of little boxes for electrical contacts that fit into those Canadian tire parts boxes and they all warped in one afternoon after I left them in my service truck.

We suspect it also has something to do with the kind of glass used.

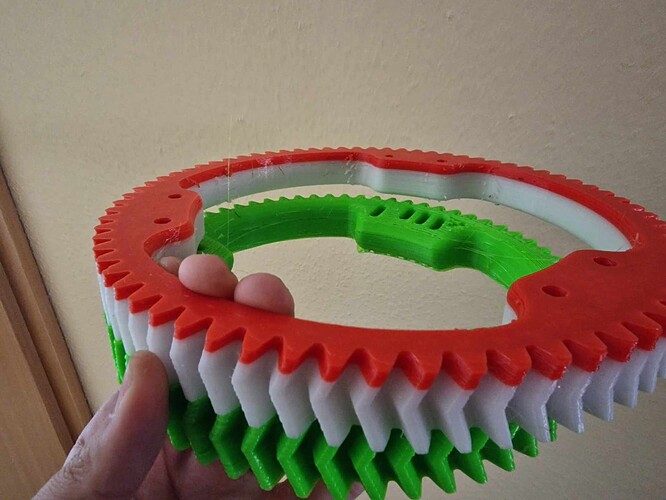

Did anyone figure out the way to create custom gears? (We might want to create smaller / larger gears to fit better with motors we were able to source.)

If you can send a drawing(sketch), I can model you anything and share with everyone

AgOpenGps | Cerea | 3d printed gear | fushion 360 tutorial | EN - YouTube I used this video for moddeling. You can choose the number of teeth and size in Fusion 360 when creating the gear. Watch the video you will see what i mean.

Just saw this video and although the testing method is probably not ideal, it gives an interesting comparison:

The BASF filament performed well, I wonder what its wearing properties are like?

I tried it as well, uploaded all the design files here:

https://drive.google.com/drive/folders/1qAt7XvSlrJfzqdrnWM-OFUAtWmS8yRmr?usp=sharing

The gear generator I used had this:

Radial System, FC=True m= 3.24 mm PA=20.0° z=70 HA=20.0°

No idea if this 20 degrees is the right one or not it seems to be meshing as a big gear. I’ve not tried to generate a small one.

20 degree pressure angle is correct, and most common.

HI !

I have trouble to print the big gear, the iner wall dont stick. Could you share your setting please !

I have a new Anycubic Kobra 2, it’s working pretty well, and fast, may be to fast?

Thanks

I’d say temperatrure is too low. Are you printing petg? I can check my settings later tonight.

You should also turn your wall lines up quite a bit(until the teeth are solid) and infill to at least 40 but 60 is best. Also reducing layer higher can help with overhangs like that.

I print petg 245c nozzle and bed temp 85c

There are more troubleshooting tips and tricks in the manual included with the .stl files.

240c nozzle and 75c bed here, first time printing PETG and these parts and all is well.

Doesn’t look like you made a brim?

I got a Neo as well, I printed the small gear for this with PETG not too long ago. Initial layer at 240C / 85C, then 230C / 80C.

Pretty much the same what you have. Are you using Cura?

PETG 4mm wall.zip (698 Bytes)

Try this profile, see if it differs much from yours.

Maybe your layer height is too high or the bed in not level. What is the temp recommendation on the spool .

JB

Ive noticed as the bed ages on the printer PETG adhesion was getting worse, especially after switching back to PETG from TPU.

But keeping the cooling fan off for the first few layers and running it at about 50% for the rest of the print has been working well. Mind you a basement in Canada might not actually need cooling lol.

The bed is auto leveling, it’s realy handy and work well. It’s not the firts layers the problem. I Use the Anycubric Slicer, has they do not give cura profile on their website. I’ll look at your profile, thank.

The first layer are ok, it’s stik well to the bed. It’s on the “inner round edge” the string follow the nozel insted of sticking on the layer below because of the angle.

Fan colling is powerfull on this printer has it’s made to be fast. I’ll try to slow it down. Thank

It was a test, so i didn’t fill it up to mutch to save PETG. I try 0.15 mm, same result.

I mist hairspray on any petg print basically. Works well

And I print the first layer slowly