Hello SK21 and Kovari;

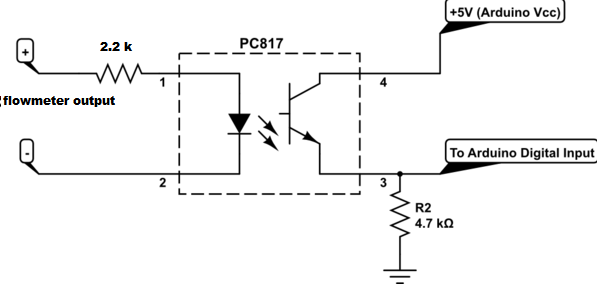

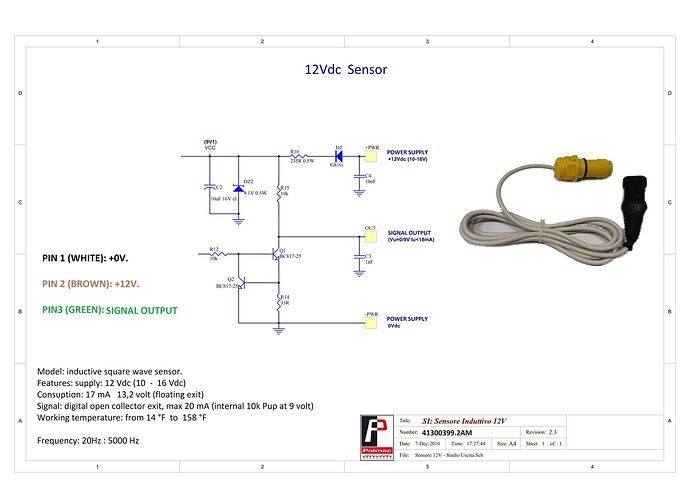

Arag usually uses 250 pulses/liter, that means 1 liter flow when it receives 250 pulses, magnetic flowmeter is 2 times more expensive than turbine flowmeters, but the advantage is that it does not need to be cleaned frequently because there is no turbine and the error rate is lower, I used both arag and polmac, magnetic and I used it with turbine, if the price difference was small, my choice would be magnetic, but the price difference is large, I am sending you the latest Polmac model that I bought and I am satisfied with, and the delivery times seem very long. I used optocoupler for 5 volt signal output in Arag, but when I used optocoupler in polmac I couldn’t get the pulses, and in polmac it worked fine without optocoupler.

https://polmac.it/catalogo/en/catalogsearch/result/?q=00375804

https://polmac.it/catalogo/en/catalogsearch/result/?q=41300399.2AM