At the 50-60 second mark it looks like it is working. I’ll test to see if I can duplicate the problem.

I also connected the circuit board with switches. Everything works perfectly except that the PWM does not adapt to the driving speed. If I set the minimum PWM to eg 100, the motor turns on and off automatically when the tractor crosses borders or the covered area overlaps.

Hi all. I redid the last sketch of the rate control for esp32. works well with wifi. does not work with ethernet. who can help finish it?

udp.zip (23.2 КБ)

In your first video the pwm was always sent, it just couldn’t get low enough. What was changed in the second video?

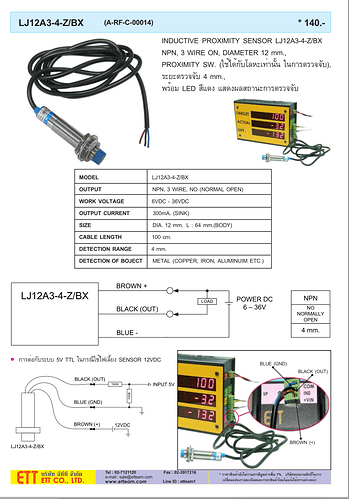

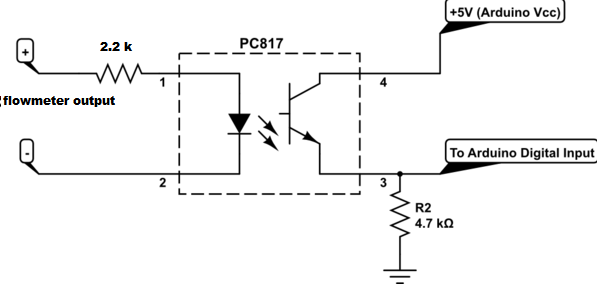

Are you using an inductive proximity sensor? Is it this one LJ12A3-4-Z/BX? If so how are you connecting it to the nano? A direct connection requires the voltage divided down to 5V. The interrupt pin on D2 has to be set as INPUT not INPUT_PULLUP. If using an optocoupler then the pin has to be set as INPUT_PULLUP, which is the default.

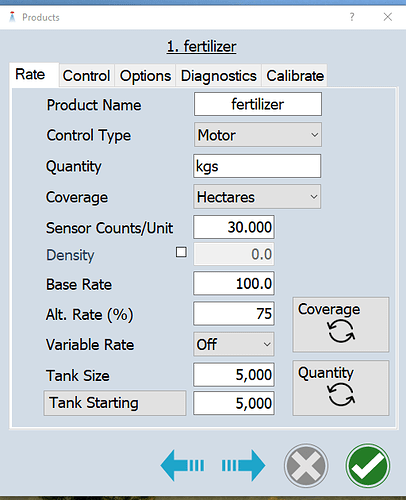

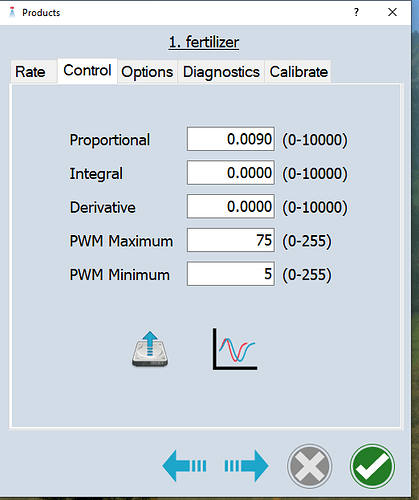

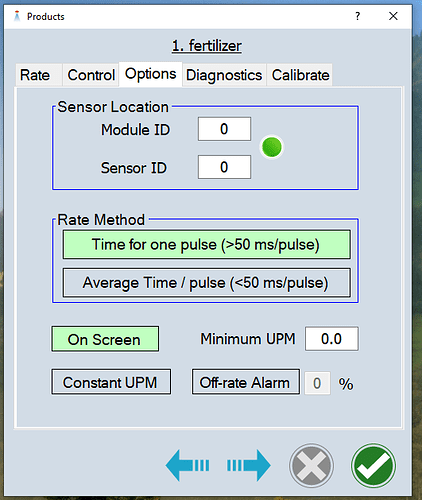

I have just tested the proximity sensor with a nano. It works fine. Here are the settings:

I just used the buttons on AOG to control the sections.

I was able to get it running last night.

The problem was solved by uninstalling the rate controller from the computer, deleting the app data and reinstalling it. Apparently there were some conflicts with the old RC versions that I was installing on the computer and nothing was able to force the RC to send PWM to the nano.

However, I have a problem with adjusting it so that the engine’s operation is stable, it constantly oscillates in a large error range, if I manage to stabilize the speed for a given speed, acceleration up or down will loosen it.

I connected the NPN type inductive sensor directly to pin D2 and pulled up with a 1k resistor to 5V. It seems that the pulses are counted correctly, dividing the sum of the pulses in the calibration mode by the revolutions of the wheel calculated on the basis of observing the marked point on the wheel, I get 14, which is the number of teeth on the encoder wheel.

If it is this type of sensor it doesn’t need to be pulled up. Pulling it up may increase the logic low too high to be recognized. To be sure the measured low voltage on the signal wire should be less the 1.5 V. Measure when the sensor is near the metal object and the light on it is on.

That’s right, it also works without pull-ups, but at first the counting of pulses jumped very strangely, accidentally. Now I think it was caused by remnants of old RC versions on the computer.

I’ll disconnect the resistor and see if it gets better.

what sensor do you recommend when I look on mouser I get so much that I don’t remember which one to take. I can’t find that sensor you sent with mouser

I have used this one with a magnet.

Also the one above works too.

@KentStuff For a luky case I have understand what is the problem that i have when I try to open the multi kml in vr section: the language…

Incredibile!

If I setting English the VR running well, but when i setting Italiano VR can’t reeding the multi kml.

Now I Will try to use and italian codification ti create the shapefile.

Now AGO, when I select +or - button Say me

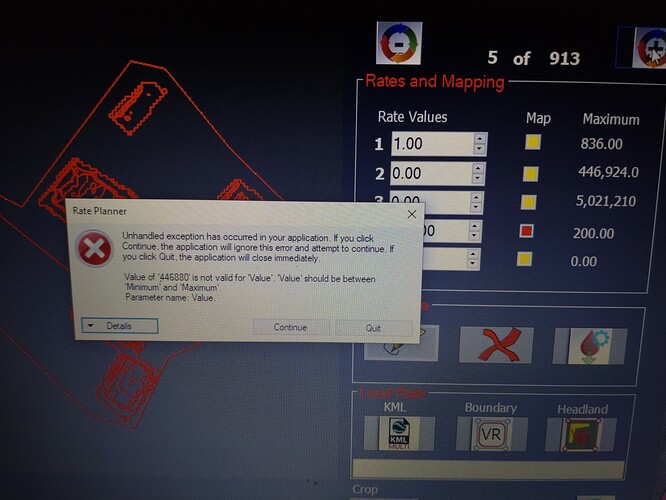

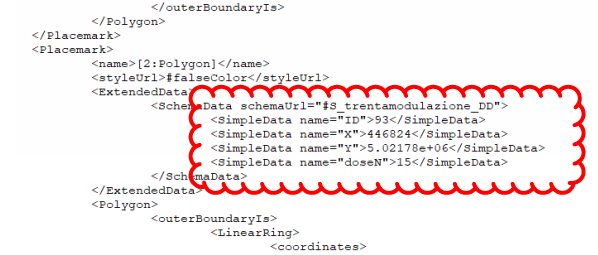

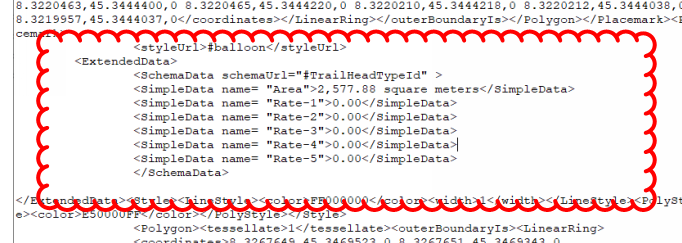

Look in your KML file. You are saving this data. You do not need to have this data in your files. This is causing the error.

It should look more like this.

Another problem solved!

When I create the shapefile export only the N rate, it’s like 30, 50, 25, 0 for example and

VR section of AOG can reed automaticaly this data.

Another time thank’s for your support!

How did you connect this Arag Wolf flowmeter?

The wolf flow meter works between 5-12 V. You can put it directly on the pcb. I just converted it based on whiterose’s instructions. But I haven’t tested it yet.

I’m wondering what hardware configuration should be used for a new rate controller setup? Nano or the newer Teensy version what will be supported in the future?

Both versions will be supported for the foreseeable future.

out of curiosity it is possible that he can also read the weight and possibly control it. as with fertilizer spreader

There has been some work done. It hasn’t been tested yet.

Working with 2 actuators?

Have you some ideas how to retro fit weight on a fertilizer spreader?