Here it says 72 pulses per gallon.

Thank you. I put 72 pulses to 1 rate and works beautifully now.

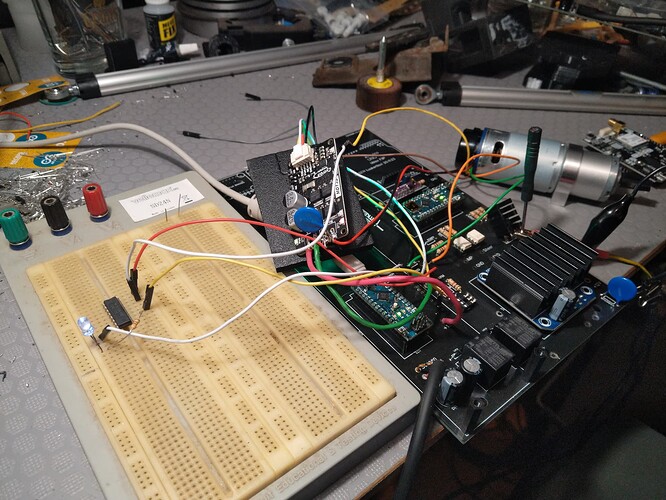

Update for Servocity / Robotech high accuracy integrated rpm sensor. I found in stock CD4017 Johnson counter. Basicly for every 10 input pulses it spits out one. Now rate control in Motor mode works like a charm

Pin 8 - GND

pin 16 - +5v

pin 14 - signal in

pin 11 - signal out

No need for external sensor or superspeed software.

@jimc are you using a simulated speed input or tying into something else for ground speed.

I was looking to use this app for UAN application. If my AOG tractor goes down how can I use the app in a non AOG tractor?

It’s alive ![]()

Completed 20 hectares and works quite well. (10% under compared to Bravo 180 ) PID tuning we might want to look at a bit more.

Calibration we didn’t do properly either.

Here’s a video about it in Hungarian.

Would there be interest for this board from a webshop?

It has 8 motor drivers for sections.(we’ll likely add option for a 2nd layer with another 8 sections)

1 3.5A mixing valve and another that’s good for about 30A (idea was go directly control the speed of a pump)

Acs712 to measure currents

ADS1115 with 4 inputs

Esp32s3 with wt5500 ethernet.

CAN chip (maybe possible isobus?)

Hi,

I built RC12 board, not tested yet. This will be put in sprayer. There are plenty pins unused in the nano. Now I’m thinking if I can easily add input for pressure sensor? I would like to have pressure reading in the screen.

This is leading me to second question. Is there a possibility to add “headland” pressure function to rate control? So the function would go like this. When going to headland and sections go off the rate control adjust pressure to preset value and then when we go back from headland and first section turns on it will switch to adjust according flow. Does this sound understandable?

As I understand the function at the moment is so that when sections are off there’s no adjustment in rate. Problem will be the low rate adjustment when coming in low angle to the headland and exiting perpendicular. We have this functionality in the sprayer control and it works well. Reason for ditching the original controller is lack of section control and flow meter. It is regulated by pressure and given flow of the nozzles.

Edit:

One additional advantage to having this function is getting the pressure in reasonable level when coming to headland in high speed and high application rates. As the sprayer doesn’t have main valve to circulate back to tank.

I can’t figure out what system you have with the behaviour you describe.

Typically there’s no way to adjust the pressure with all sections off if it’s flow controlled?

Except if it’s an variable speed pump?

Or throttle valve on the bypass line?

I guess you will have to tell what type of pump you have(especially if it have some speed control) or where the throttle valve is installed (if applicable).

Mainly all sprayers here are diaphragm pumps connected directly to pto. Flow/pressure is regulated by three way butterfly valve. So pump speed is constant. When sections go off flow stops but pressure remains as the pump is in constant speed. There for we would switch the regulation input from flow to pressure and back to flow when first section will open.

Ok, I have never seen an 3 way regulating valve. Or it just have an integrated relief valve?

Could you post a link to one? I would like to see one.

For diaphragm pump I have only seen some adjustable valve with separate relief valve.

Remember that a diaphragm pump will never output “no flow”. It will burst somewhere if the flow is restricted too much.

Yes we have also relief / over pressure valve in the circuit. Opening pressure is somewhere around 12-15bar if we run the pressure that high it makes unnecessary load for the one way valves of the pump and some chemicals have tendency to start foaming when relieved back to tank from that high pressure.

I will dig the hydro scheme later.

I’m quite familiar with different types of sprayers and how they operate.

The nano code could be modified to read from one of the analog pins. There is a pressure display in the app. It may be possible to try to set the pressure when the sections are off. The nano memory is nearly full so there is not a lot of room for extra code.

I would like that.

So your butterfly valve must be quite fast if it currently can regulate pressure from boom closed to fully open.

I have a 30 year old sprayer with his old controller, works great in normal conditions but is way to slow to let sections open/close automatically. I can take 3-6 seconds to reestablish to correct rate.

How fast are the modern valves?

What model would be the fasted?

I’m looking to change my adjusting valve and relief valve, so I could ditch my controller and use RC.

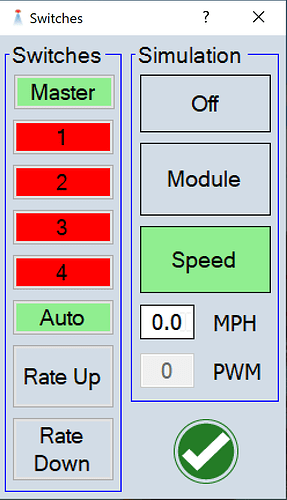

I am only using speed from AOG.

We have backups of our AOG stuff in case there is a problem we can replace it quickly and get it back going again.

You could just use simulated speed then you would need to actually drive that speed for it to work. I have not looked at the latest version that SK21 has released but you were able to do this in the switches panel.

I’ve got the RC11 board, programmed the Teensy and got an Ethernet connection to the RC app.

What I’ve not got is any of the relay LED’s lit, only the power LED. I can’t get any of the relays to obviously switch either, no clicks or LED’s coming on/off.

When I power the board on, the wifi board briefly flashes blue, a relay clicks, power LED comes on and the teensy orange light flashes.

Everything on the board looks ok, no smoke or flames, but I’m obviously missing something!

Things to check:

- module config for board and relay type

- subnet set in app, upload to module

- section count and width set

- auto off

Thanks very much, that’s fixed it!

In the module config screen I’d not clicked on the up arrow to upload the settings to the board, I assumed the save button did that.

I’ve got all the relays & associated LED’s switching now. Next step to fit the Cytron and get the variable rate motor for the seeder going.

I assume that rate control will work without a feedback encoder, just be able to set a motor speed and calibrate?

Without an rpm sensor you will have to manually set the speed to a certain pwm value.

Good morning,

I would like to control a bold sprayer which has a 3-wire flow meter and which is in reverse polarity for section cut-off.

I was thinking about the RC8 PCB?

What do you recommend to me?

THANKS

Hi everyone. I have built the nano version of RC8, but I don’t know if I have a hardware or software problem. Is there anyway to see the data from my raven flowmeter? Can I check the voltage at the control valve?

I’m using this pwm hydraulic pump

Should I be set to standard valve in settings? I am kinda lost…