elobau sensor on my massey ferguson 7475, 3d printed arm.

John Deere 6230 with RTY090HVNAX (Ordered 12V edition by misstake) and 3D printed adapter for 8mm rod

Adjusting the nuts for optimal utilization of range on the sensor

Jaki dokladnie czujnik wstawiony ?

wielhoeksensor, om de actuele stand (stuurhoek) van de stuurwielen te meten. meestal word daar een hoogtesensor van een auto (range/land rover) voor gebruikt, maar er zijn diverse mogelijkheden

het is eigenlijk gewoon een potmeter die 5V binnen krijgt en naar gelang de stand van de wielen 0 tot 5 volt terugstuurt naar het systeem

Huh pools denk naar nl??

makkie toch? ![]()

![]()

![]()

![]()

Als hij geen google translate gebruikt dan doe ik dat ook niet hoor, wat dat betreft ben ik makkelijk, gewoon engels is het makkelijkste op zon forum

Hahaha, das waar

Hi

You don’t have to use google, there is a good alternative translate at DuckDuckGo

Kim

Haven’t seen any Belarus WAS mounting ideas, this is how I’ve done it.

Hope it helps someone… ![]()

MTZ 892.2:

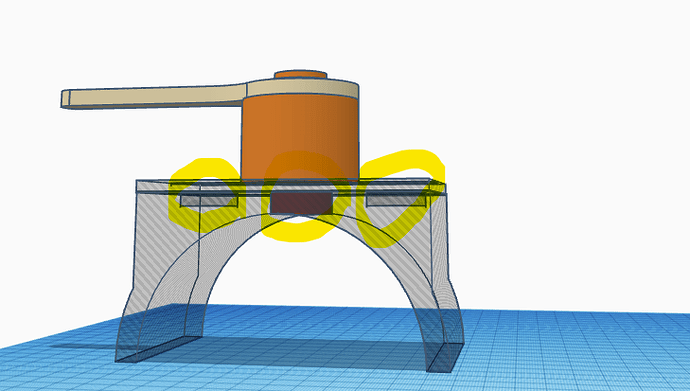

I am looking to print a 3D bracket for my WAS to sit on and would like to use magnets to hold bracket to the steering knee for easy removal and placement. Using the Delphi ER10031 will the magnets have any affect on the WAS signal? I read that a hall effect senor could pick up interference, not sure on the Delphi? See pick for reference of magnets circled in yellow.

The Delphi uses a Hall effect sensor but I doubt that the magnets will be close enough to affect operation. I’ve definitely seen pictures of AOG setups that use magnets to attach the sensor.

My concern would be that if the magnets slip, your center point will change. It’d be a pain to drive through some tall grass/weeds and have to re-zero.

I used a long hose clamp around the axle tube to secure my 3d printed Delphi mount. It won’t snag crops, doesn’t shift, and won’t fall off.

Magnets will definitely interfere with the operation of the sensor even from a considerable distance.

Use only non-magnetic stainless steel screws to attach the hall sensor, e.g. RTY honnywell or similar. The use of iron screws causes the sensor to malfunction.

I think the information about the screws should be in the instructions. Many make this mistake and the wheels wobble, just change the screws and we have a straight line.

how far away does the closest steel have to be from a honywell rty sensor ? even using steel bracket to mount the sensor will that interfere with the sensor readings

Well …mine is mounted on an iron plate, and even with iron screws. I have not noticed any malfunction of the sensor. I know we are supposed to use plastic screws. Iron screws might interfere the most, as the plate is all around the sensor.

dont know i guess . i had been using a sensor that worked but it gave up. i installed a honeywell sensor and the machine drives all wobbly like it didnt before i wonder if i should try SS screws.

hey anyone using a homeywell RTY Sensor? Contactless with a magnet?