Does anyone have pictures or which sensor was used on a lexion combine model 750?

Deere 8100-8410 and maybe others with 1300 front axle.

https://github.com/WildBuckwheat/Deere-8x00-WAS

Deere8x00WAS.zip (190.7 KB)

Is there an stl file for the mount available?

RQH100030.zip (50,4 КБ)

Has anyone designed a 3d printed solution to extend the arm on this sensor?

I did it for myself, only with a bent knee. What length is needed, I can make a 3D model.

I need about 7.5 in (19 cm) from pivot to pivot point. Thanks for offering to help!

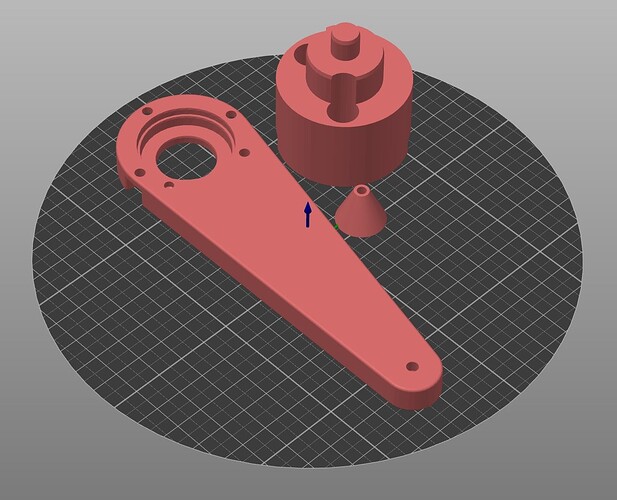

Try it, maybe you need to adjust something.

Body1.zip (10,9 КБ)

Any hints how to mount steering sensor on Kubota M7060/M4?

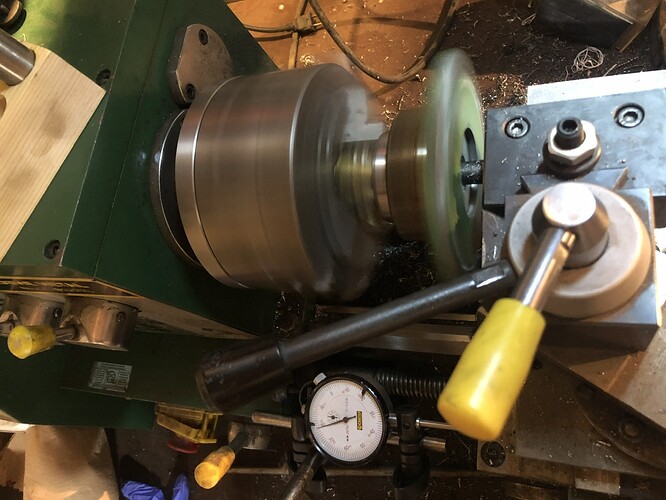

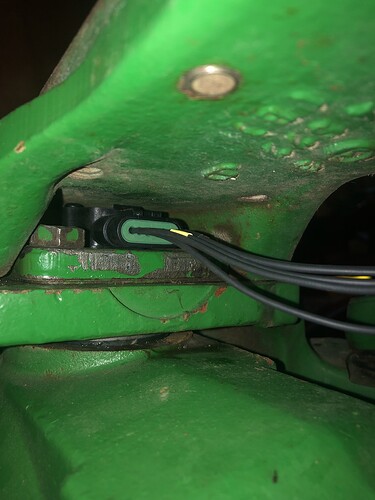

My John Deere 7410, machine for Deere spring loaded angle sensor. A small 3d printed adapter and allen key complete the mechanical connection.

Hello,

This is the John Deere sensor, Deere RE575331, or equivalent aftermarket sensor, you have used here?

After reading the wiki on wheel angle sensors, I bought a similar sensor, not original Deere, but should be a replacement part. I liked the fact that it is spring loaded, but was surprised when it arrived, that the sensor have a 180 degree range (both mechanical and electrical it seems to me).

I instantly knew it would be impossible to use the whole 180 range as a WAS, but tought I could atleast arrange something that would get me near the full use of the range. This proved to be harder than I first expected, so now I am thinking it would be much easier to use much less of the range.

In your setup above i expect the range of motion to be somwhere around 90 degree, am I correct?

Is your sensor also a full 180 degree sensor?, and if so, is it accurate enough used at only about half its range?

This is the A&I version of the Deere sensor, it is indeed spring loaded with 180 degrees of range and the installation uses only about 90 degrees.

The tractor is sitting in the shed with all the panels off waiting for a valve and harnessing, so I have not tried driving with it yet. This sensor is fitted on many Deere tractors in the kingpin and there are people here using that sensor by reading only 1 signal (sensor powered by Deere harness and AOG reads 1 analog signal). I believe Baraki also sells and installs this sensor.

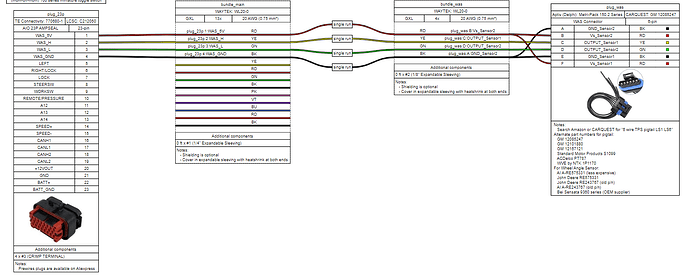

In my case, I am going to wire the sensor for both analog signals and use the ADS on the AIO board in differential mode.

So I’m using half the effective range of the signal, but reading both signals should double the precision. That should cancel out and I expect that to work well. From there I can try reading only one signal and seeing if that is sufficient, I expect that it is, since others must be doing it.

This harness schematic is a work in progress but it has all the alternate part numbers for the sensor and part numbers for the pigtail, so maybe it’s of use to you.

Thanks for your reply.

I had no idea both sensors signals could be used at once. I hope you will let us know when you have tested, if there is a significant difference between your two or one sensor setup.

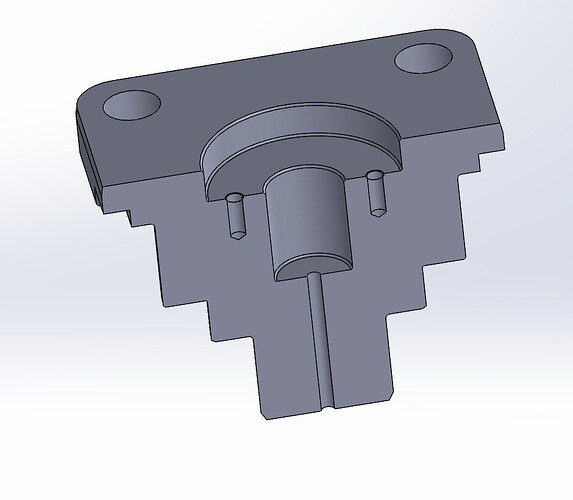

I love this installation. I am will be doing this next winter, do you mind sharing the STL for the adapter?

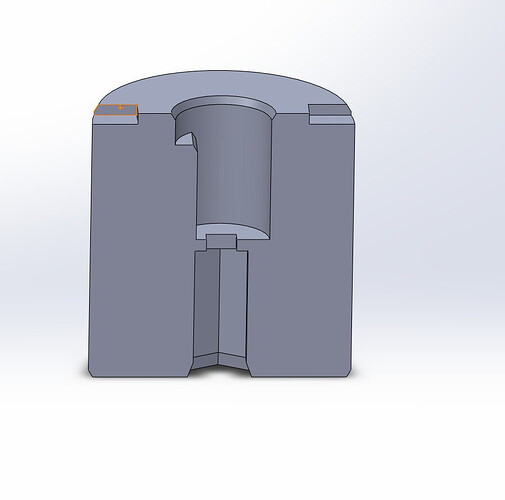

Thank you for the compliment. Please find the file attached, for 1/8" allen key. Print with hex side down, no supports. I’ve included the solidworks file in case you need to play with sizing.

WAS_HEX_Adapter.zip (163.8 KB)

Rotary hall effect sensor with a separate magnet, that is fixed over the top of the track rod end.

I printed a holder to hold the magnet in place, but would probably just glue it down in future. The main part of the sensor is set into a printed housing, which helps protect the fixed wires coming out of it. I would have used a Honeywell RTP, with a plug on the sensor, but they have more than doubled in price in recent years.