is there room over the main cylinder body for a linear sensor?

mayby i could fit it. But the problem is that piston(that part that moves inside and outside from cylinder when turning) has free rotates around itself and does itrandomly during use (also I can grab it with my hand and turn it around) so it will damage the sensor. I made rotary sensor instalation and it worked well except for problem with the piston rotation - when this happens the rotation of the piston affects the reading.

Just have a look at the first post of this thread! Many usefull examples of that Carraro Axle there!![]()

sure before posting i look at whole thread, I also looked for tips in other topics and places. To be honest i didnt find many examples installations on this type of suspension but mayby i didnt see or understand something. Could you be more specific?

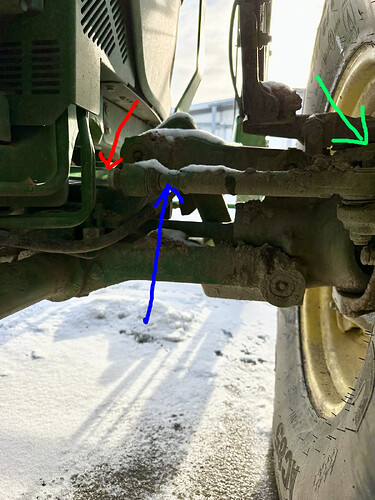

I could find many instalation (linear or rotary) to part that i marked with red arrow but i cant do that - this parts rotates around which distorts the rotary readings and will damage the linear one. It would be perfect to use the part marked in blue because as it is already behind the joint and no rotation on it, but on every bump this part moves up/down and in other directions, which also affects the sensor.

In the examples I found major modifications to use the location marked green (from what I know, the original sensor is located there if there is one - in mine there is no space for it so I would have to make a lot of modifications ), and from what I can see it is a very large modification requiring a lot of skills and equipment which is beyond my scope.

I hope that maybe someone has another, simpler solution…

does the part exactly half way between the blue and red line turn also?

do you mean the thicker green part? joint housing? yes, it turns with the piston. There is rubber at the end and then the part marked in blue comes out.

Does the part behind the green arrow move? Can you take a shot from above and behind?

yes, it whole moves together with the fender, i’m thinking the way i attached photo is only possible at green mark but as i told it reqire lot of skills ![]() Unfortunately, I am not able to take a photo at the moment because I am not close to the machine, but I will try to take one and add it.

Unfortunately, I am not able to take a photo at the moment because I am not close to the machine, but I will try to take one and add it.

i mounted mine to there,it has the potential to turn but ive never seen it turn

post 12 on this thread is my instal

Have a look at picture in post 6. This is how I have mounted sensor on these type of axles.

Unfortunately, in my case it turns, I did a few tests to check it

I saw this, this part does not rotate all the way around it is true, but it moves a lot when turning and moving the wheel up/down on bumps. I was wondering if this is a problem for you… perhaps because it’s a small tractor in my case and everything is very small and tight, hence the greater range of motion in my case… what does it look like for you?

If you set it up so the joint on the top of the sensor arm is in alignment with the joint on the end of the cylinder when wheels are centre it works well. No signal change when suspension moves. There may be some error when at full lock but centre is the most important.

The part you attached to moves not only up/down on bumps but also front/back when turning, so I excluded it - mayby wrong. You don’t have any problems with it? Does this movement wont break/damage/distort your sensor? Below is my video of tests when I hooked on the piston - you can see the movement I describes during turn.(the video is taken from the top).

It can’t be good, as navoye82 said

If you mount sensor on the right, near hydraulic cylinder, pass the ball joint, then it will work well.

Works perfectly, this is exactly how the OEM WAS is fitted. It’s a Class bracket I’ve used.

The two fixings points are in reference, go over a bump and this carraro axle moves a lot and the autosteer is perfectly straight no wiggles.

Perhaps the best solutions are a linear sensor, parallel with the hydraulic cylinder or one mounted on the king pin.

I had a similar setup on my non suspended front axis. However the zero point changed a bit over time causing steering problems. Recentlty I moved the sensor directly over the pivot point and everything got much better:

That looks very neat!