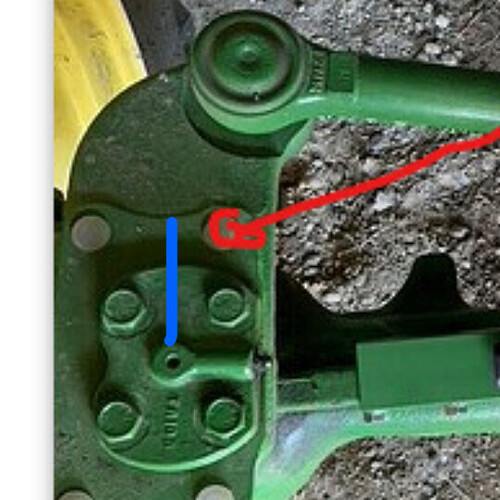

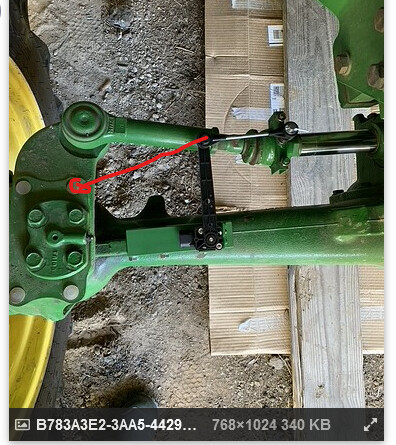

Here is one I made for my John Deere 5055e. It is a Land Rover RQH100030 sensore. The axle had a vertical boss about 4" long by 3/4’ high cast into it. I drilled two 5/16" holes and threaded them to mount the U-channel that forms the base of the sensor bracket. The piece that holds the WAS is just some 1-1/4" angle iron. The piece on the steering cylinder is a 2-1/4" ID muffler clamp with a piece of letter R drill rod welded to it.

sorry not the best

this parts of cylinder can rotate

move to the rod that roation is limited

or better to the pivot ( fender fixation )

So you have a 5055e? Because I drove for 2 hours today and did not observe any rotation of the steering cylinder.

The tractor has no fenders so it might be hard to put a sensor on the fender.

i havent this model but jd so i know that cylinder is free… so wait and see

for the other solution with pivot find this idea

I don’t have a JD, I have a case and for more than a year I had the sensor like you, but a day came when the pivot turned and twisted the sensor. Now I have put it on the part that does not rotate instead of on the piston, no problems.

I’ve found the red line doesn’t change as linear as the blue line. Build a bracket between the 2 bolts and mount 90 degrees in line with the pivot.

Custom made metal case ,inside 0-360 degree rotation sensor output 0-5V .

Also inside metal case , one shaft sealing ring and two ball bearings.

0-360 degree rotation hall sensor

Have you used this yet? There have been several painful experiences with 360 degree sensors. It is not generally advisable to use a sensor with more than 180 degrees of range. The more degrees, the less WAS precision the autosteer PCB will have.

Full left to right reading 2V (rotation 160degree)

Ackerman 55

Counts per degree 60

I need help. Can I attach the sensor pictured below to the wheel angle sensor

help

Can I attach a sensor like the photo above to the wheel angle sensor? There is a problem with the tractor structure. The existing angle sensor cannot be attached. My board is Micro All-in-One 4X.

thank you

AOG does not support these type of gyro sensors. That sensor will not work.

Hello - I am trying to put autosteer in for my dad on his JD 4240. Wondering where the best spot for the WAS is? Is where I have the blue triangle?

I would 3d print a socket type adapter and put the WAS directly onto the kingpin bolt.

Hi this is my quick fix just to use the system on JD6200 using Toyota LandCruiser accelerator pedal position sensor until I do the king pin mod

John Deere 5055e WAS version 2.0. Flat plate between unused fender bolt holes (thanks HobbyFarmer) with coupler nut welded on. Miniature ball joints on both ends. U-channel and angle iron for the Land Rover sensor holder. Hopefully this version will pass muster. ![]()

Are there any inspirations/recommendations for protective housings? I’m currently thinking about making a protective housing made of metal or 3D printing on a Fendt 300 LSA for a Delphi sensor. How much protection does the sensor need? Does metal affect the signal?