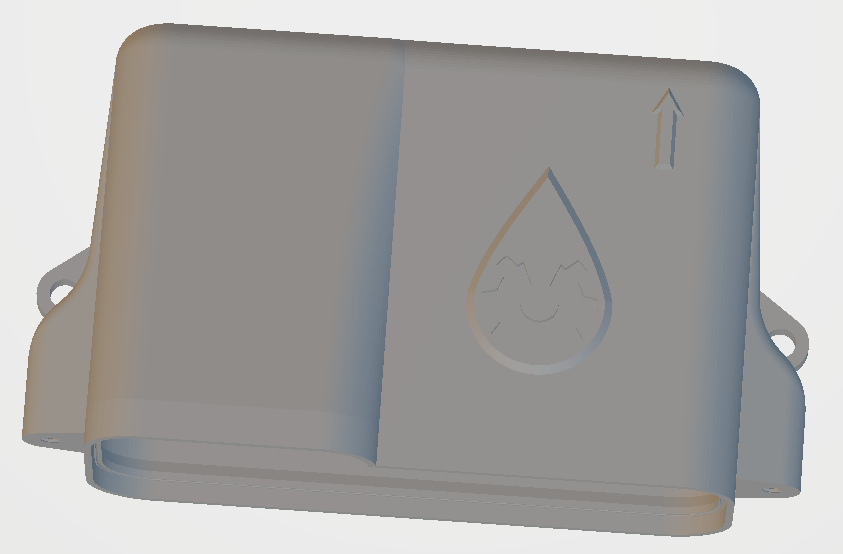

Your top should be the bottom. Print it like a bowl / vase.

rotate it 180

as said like a bowl.

and make a suport because of botum edge is rounded.

Anyone know what this arrow indicates on the micro enclosure (post 5)?

I figured “point this end up” but the logo is upside down then

I think this should point forward(direction when vehicle moves forward) because of IMU

I realize many are moving to the newer v4x AIO. I’m just getting to the 5 ver 2.4 that I got last year. I’ve been trying to get some advice with soldering the missing components on the telegram channel, but no response. Is this because the ver 2.4 board is problematic? I’m almost ready to put everything together. Is this board going to be okay for simple guidance?

There’s nothing wrong with the 2.4, that can’t be fixed. v2.x board issues fixes · AgHardware/Boards Wiki · GitHub

But I don’t know on the missing components.

Here’s the link to the message on the telegram chat for the board experts Telegram: Contact @agopengpsinternational

I think it’s more that no one is asking v2.4 questions anymore because anyone that’s ordered v2.4 has already got them fully assembled and installed in a tractor. I’ve got 2x v2.4 in tractors myself, they work just fine.

I’m just finally getting to them and I know they didn’t have all the pieces soldered on. I have a picture in the telegram chat that I was hoping to get some clarification. Otherwise I think I’m good just reading the discourse and github files.

I also have around 30 machines running them.

Steering kickout doesn’t work with 12V motors but for hydraulic installation it’s great.

2 layer V4 is definitely nicer but wouldn’t throw out any V2 board because of it.

Also, the dual-CANBUS but also analog WAS is still a useful option

My steering (current) kick out works with a 12v motor on a v2.4. What’s stopping yours from working?

I have 2 identical 2.4 Std all in one boards that I have built, and everything works except the current kick out. I have the 24 volt motor, and using a remote steer switch. I made the modifications to the cytron to allow the current disconnect. When I set the amperage very low, I’ve had it seeming to kickout, and reengage immediately, and repeat that So when I grabbed the wheel, it would jerk, and beep at me.

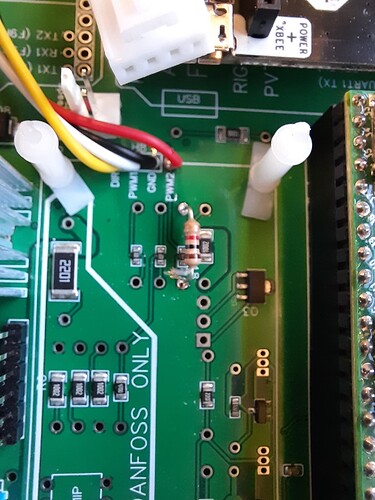

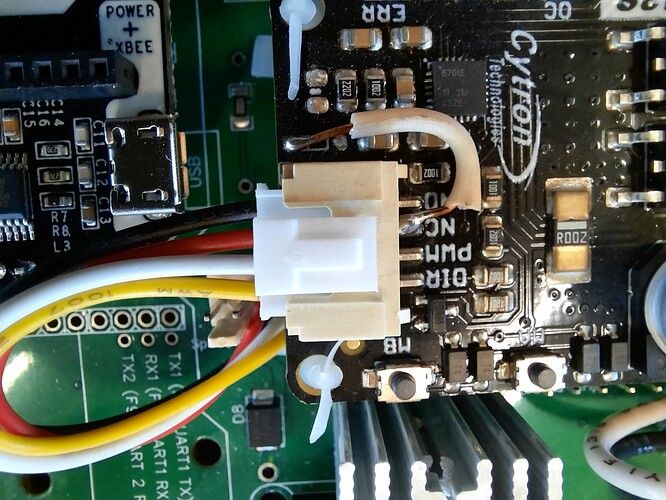

I already had the trace cut, and a 330 ohm resister in place as a fix to the original v2.4 board problems. Then I saw Davidwedel’s post above regarding v2. board fixes This post recommends a 1k resistor instead of a 330 ohm, so I replaced mine. Now I can’t seem to get the cytron to send anything to the motor. There’s power at the cytron. Everything is green in AgIO, The steer switch still shows a change in the PWM value on the screen when I switch it off and on.

What are others using for that resistor? Any other advice?

Check the voltage on the white jumper wire at the Cytron when steering is on & off.

With regards to the reengaging immediately, are you using a steer “switch”? That mode has a glitch in the official firmware that rengages once the fault condition is gone (ie over current went away because autosteer turned off)

m_elias, thanks for the response. I will check the voltage as you mentioned, and thankfully I have a second board that I can compare it with.

With regard to the code problem when using the switch, I found a topic on it.

https://discourse.agopengps.com/t/reactivate-auto-steer-switch-after-current-limit/8526/5

I will try that code fix, and/or convert to using a button instead of a switch.

Hello,

i would like to use the speed pulse to switch a cover crop spreader on and off. Is there already published a Arduino code for this? The Arduino should close a relay as soon as a pulse comes. Thanks in advance!

You could also use the section control side of things to control it. Could have it turning on and off to a boundary line or on coverage.

A simple relay board linked to a nano to control the switching.

![]()

I could use that too, right.

I rigged up a 12 row beet drill to section control and it works very well. All the codes/ino’s are available and easy to do

The only problem was that i have two machines in the three point hitch at the same time. The cultivator is controlled by AOG. The spreader should only be controlled via the driving speed. So i got it working with Arduino pulseIn() function and a relay.

Can you explain what you did? Activate a relay anytime there’s an input pulse?