Look here: GitHub - lansalot/Boards at CANBUSEnable

Hello, i will try to connect to an axion 870, where is the steer can-bus in this vehicle? Thank you.

ATP module, under panel next to seat I assume

Ok , that is, and it is working, I have been testing today and comment two things:

Nav Controller address was 1B ( in teensy project was 0x0CAC1E13 , in this case was delivering 0x0CAC1B13)

After a while of working ( 2-3 seconds) appears this message: id0687h on tractor screen, does anyone know the meaning?

Have you changed the pved valve parameter and made the bridge plug for the atp module 16 way connector? I suspect by the error code you haven’t.

No I havent changed pved and made bridge plug, can you give me a link where this is explained ?

It hasn’t been documented properly. There are some notes in the teensy INO about it but also not complete. To change the PVED parameter you need to open serial monitor and connect to teesy and put it in service mode by sending “S” then whatever the next option is for setting the PVED parameters. when sending the parameters the valve must be on and once you write the parameters you need to send the commit command to save them in the PVED then restart the PVED.

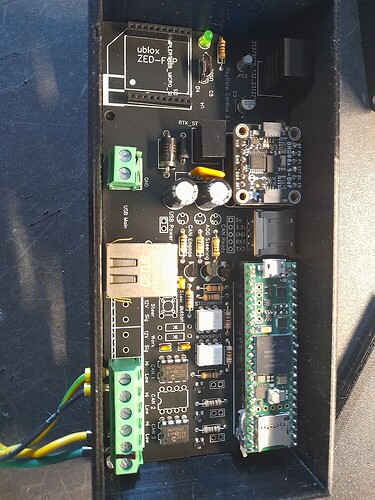

What board are you using AIO or Tony canbus?

Here are some wiring diagrams of what i have suggested to some others. The Tony board one has a relay that powers the safety solenoid valve on the orbitrol but i think the recommended connection point on the PCB for the relay is wrong. I think someone said they connected it directly to the teensy pin for PWM2.

The bridge plug diagram works for early claas tractors pre mother reg but without the added element of safety by using the relay. on later tractors you need to make a breakout harness that passes the WAS signal through to the ATP and also with the pins looped like what is in the tony board diagram.

The ATP module is under the cover in the floor beside the seat.

CLAAS Tractor AOG wiring Tony board.pdf (118.4 KB)

CLAAS Tractor AOG wiring bridge plug.pdf (22.4 KB)

Ok, i have read in agragps manual that it is needed to calibrate with CDS , would be equivalent to the setupPVED() described in can_service_tool.ini?

Calibration with cds is advised but won’t stop it working and calibration should have been done by dealer at predelivery check. Calibration with cds is different to the pved setup with teensy. The teensy can change the parameters in the pved to ones that suit our use for agopen.

Had a CPD of 24 on a MF7726 today, I thought it seemed low, so good to hear others have found similar with Agco tractor.

7726 behaving a bit like the Valtra too, will try next week to calm it down.

Nah that’s pretty normal for sure with AGCO.

Hi, maybe totally wrong place to ask, but how difficult is to build a CAN bridge to Deutz fahr to use jdLink?

Has anyone tried to tie the work switch of AGO to the state of the integrated hectares counter on a Case tractor?

Or if not, how can I add a custom can message to the sketch for the work switch?

Is a AIO board suitable to autosteer a Fendtone with AGO. I understood I need connect to V-Bus and K-Bus and maybe to the Isobus, but how to do this? The ampseal connector has one CAN bus only? (I have the AIO V4.2 board.)

As you know, that board only has one CANBUS, so no - not suitable. Get the CANBUS one instead.

But the CANBUS board doesn’t support any f9p. Is there no way to add aditional CAN Bus to the standard AIO? I have it already.

Yes it does