Good work @Raycorp

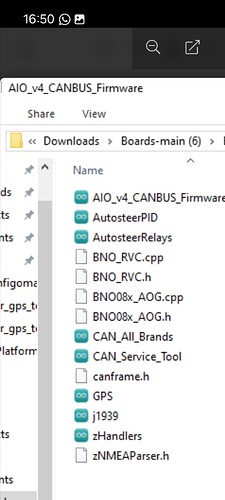

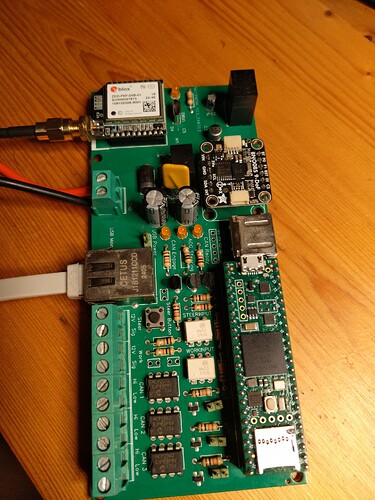

I am making a canbusbord, flashed “Autosteer_AOGv5_Teensy4.1UDP_SteerReadyCAN.ino”

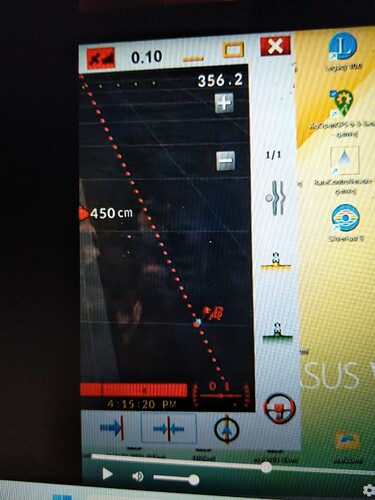

When I start it up BNO is working for maybe 10-20 sec then it stop working, it is still gren in AGIO but no respons when I tilt the BNO, what am I doing wrong ![]()

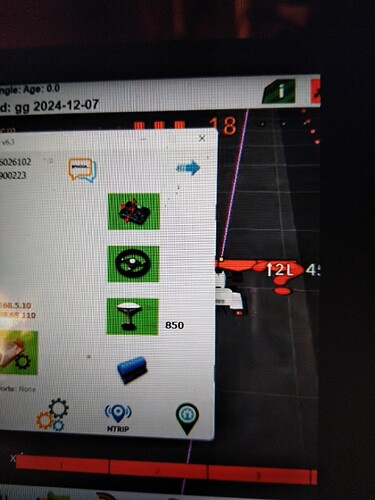

It is this board, with v4 firmware I cant see the GPS

I tried too connect too a gps using a com port but BNO was stil not working

Well its working now, maybe a bad connection on the board

Hello, does anyone already drive a New Holland T7 new model, or New Holland T7 new model? With Can Bus steering via Teensey?

Has anyone actually managed to read the activation switch for steering activation via joystick on a New Holland? With Can Bus steering

Yes I was able to read it using SavvyCAN on a NH T7.235.

Here is a decoding of the handle in the picture below:

Message ID: 18FFB306

0x03 to 0x13 (byte 2) bit 20 go to 1 for button on back

0x03 to 0x13 (byte 6) bit 52 got to 1 for down shift

0x03 to 0x07 (byte 6) bit 50 goes to 1 for up shift

0x3F to 0x7F (byte 4) bit 38 goes to 1 for backward direction

0XFC to 0xFD (byte 5) bit 40 goes to 1 for forward direction

0x03 to 0x07 (byte 2) bit 18 & 0x03 to 0x43 (byte 6) bit 54 for the auto button

Message ID: 18FFB406

0x03 to 0x07 (byte 5) bit 42 goes to 1 for autotrak button

0x03 to 0x07 (byte 1) bit 10 goes to 1 for rear hitch up

0x03 to 0x13 (byte 1) bit 12 goes to 1 for rear hitch down

0x03 to 0x43 (byte 1) bit 14 goes to 1 for turn around

Message ID: 18FFB606

0x02 to 0x42 (byte 3) bit 30 goes to 1 for left on d-pad

0x02 to 0x12 (byte 3) bit 20 does to 1 for right d-pad

0x02 to 0x12 (byte 1) bit 12 goes to 1 for up d-pad

0x02 to 0x42 (byte 1) bit 14 goes to 1 for down d-pad

Have you WAS with can ?

or in pcb

The tractor is steer ready so had wheel angle sensor fitted.

I just connected the Can H and L wires as shown and the steering angle should show in AOG.

on the 7624 there is a seperate canbus for the joystick. you can use a cansniffer and find the messages from the joystick. with a little scatch you can enable steering with any button on the joystick

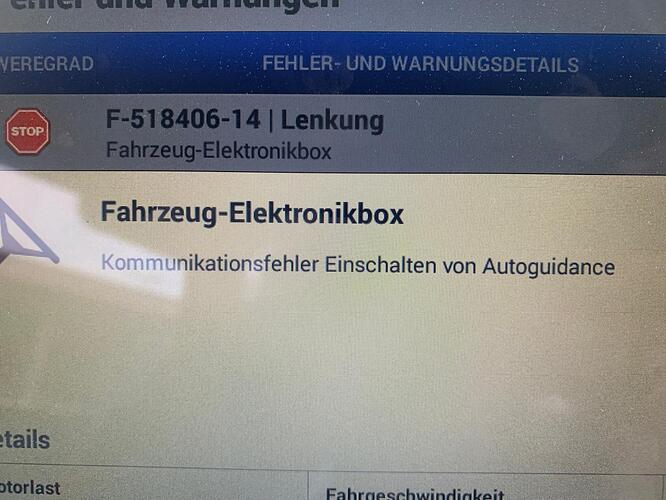

Hello, have you ever looked at the new New Holland, new model, with Can steering? I tried to control it with Case IH Tester, but got error messages.

The predecessor with Can steering worked perfectly.

Ive been told from a fitter who works with new holland that they have started putting a 3rd party lock on gps. He thinks you now need a laptop connected to change the 3rd party code

Firstly, sorry for replying to an old post, but I’m having a hard time browsing the discourse forum as everything and everyone keeps posting in the same thread. And mos of your related pictures uploaded do not show up any more.

Would you care to give an update on the project of autosteering a non-autosteer-ready Valtra N/T4, or point me in the correct direction where you have done so?

I saw some of your youtube videos, but haven’t seen anything on a nonautosteer Valtra T4 in the making. Was this project for a friend of yours?

I have a Valtra T174 first gen myself, and I can see the WAS+SASA wiring, but am missing autosteer-buttons and “gps-ready”-harness in the cab, so I’m about to dig in on the orbitrol to see what kind of Danfoss it is. I’m waiting for some CAN shields for Raspberry Pi, but I think I eventually have to crawl back here as I most probably need a steering-ECU anyways. And I have no idea if the Danfoss is even turnable via analog or CAN.

Do you have any suggestions on what to look for on my T4 to conclude if this is even feasable?

I also have an old Valmet 6400 which would be great fun to retrofit a PVE, but that’s another topic. ![]()

If it’s the pre-Smart Touch the orbitrol is with PVED-CLS and there’s a separate SECU in the tractor. With this you can basically hook up to the steering CAN with Danfoss service tool and enable the GPS steering on the orbitrol, then hook up into the CAN bus, can’t recall if it needs some HMI messages on the bus to switch between fast steering and normal steering.

Second option is to reflash the steering ECU with autosteer software and add th button to the armrest. But no valve/actuator modifications needed, it’s the Danfoss unit there and all the hardware is already in place if you have the fast steering (which you have since you have the SASA & valve in place)

I retrofitted the whole OSPE steering orbitrol to the T4, so it’s basically the same setup as the original but I have my own steering ECU feeding the speed signals etc. to the controller and my own software calibration on the PVED-CLS.

I might’ve fooled myself when looking at AGCOs parts finder and the schematics. I finally had a look at the steering unit, and it’s clearly a Danfoss OSPJ 160 LS version without any electric solenoids attached to it.

And, to be clear, the cab does not have any quicksteer nor twintrack. The SASA impression was made by looking at the schematics for a twin track version sent to me by the local dealer.

So, that brings me back to start. I think I’m better off putting the money on the old Valmet as it’s the one doing the precision art in the yard ![]()

You can do the T4 exactly in the same way as the old 6000-series with e.g. Danfoss PVG valve or any other setup for the LS system, the system is bascially the same for both. There’s nice space for the valve on top of gearbox under the cab

I’ve got a pretty steep learning curve by now, and I think I’m finally getting a grip on the Danfoss orbitrols.

Are you saying it’s as easy as swapping the OSPJ (J as in probably AGCO specific model) with a matching spec’ed OSPE valve, and then choosing the correct electrohydraulic controller?

Did you end up going for a PVED-CLS yourself and using Danfoss’ curvature commands over CAN, or did you make your own controller between AgOpenGPS and the PVE?

What about the SASA sensor - is it included in the PVED?

Thank you for taking the time to answer all these newbie questions!

Does anyone know if it’s possible to steer the S4 Fendt via Isobus? I think I might’ve destroyed the VBus. The tractor was at a mechanic for unrelated things and they did a software reset. Afterwards the VBus didn’t work anymore. Tried different Can module, different programs everything, it just doesnt work at all on the VBus. I suspect they might’ve connected one of the can pins to the 12v in the diagnosis outlet… When I connect the cable to the Vbus I get an error flag by the mcp_can library after sending, when I connect the cables to the isobus it sends the messages successfully. I checked with a second can module to see if messages are actually being sent and they are. It all seems like nobody is listening (and acknowledging packages) on the VBus anymore…

Because of the software reset I also did a steering angle sensor and steering valve calibration, both worked successfully. The hydraulic steering also works, as I can enable it on the armrest. The VBus at the diagnosis outlet has a constant 2.5V on Can-High and Can-Low, so something must still be connected to it. Does anyone have an idea what might be causing this problem? What component is connected to the VBus and where can I find it?