You got it… Its alwayd trying to get back to neutral (2.5)… the further away the more it will open the valve to try to return.

So you could do this with a Cytron and send voltage like a rate controller, just vary the voltage like a motor with 2.5 volts being the neutral position?

It’s sometimes tricky, for example if the cytron’s PWM input gets turned off, then your output goes to 0v. I think better would be to create a 2.5v reference and then use the Cytron to pull that up or down to control the valve. Then if something happens with the Cytron then at least the valve goes to neutral.

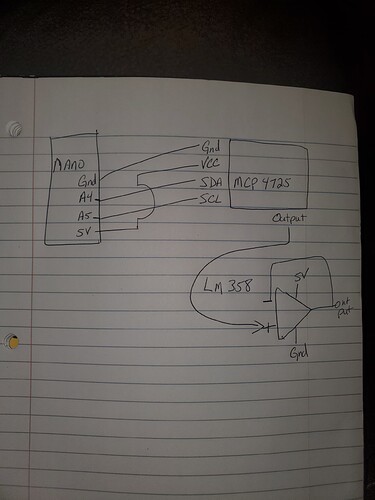

I did not use a Cytron, I ended up with a nano tied to a mcp4725 (i2c dac) and a LM358 op amp to use as a buffer to make sure I didn’t overload the dac.

Technically I could have just used the opamp on a pwm pin of the nano, but I wanted a true dac to send signal to the tractor.

I hook both ground and 5 volts to the machine. This keeps the arduino running as long as the tractor has power, and with a watchdog timer that defaults to 2.5 volts after a second if the arduino doesn’t get new information.

A short video using random data in the target,actual,/n format for ezigrade.

https://youtube.com/shorts/pHxKV5jln5k?feature=share

I plan on working on the code for opengrade this week while it’s raining

Very interesting, I had to Google a few parts in your diagram but mostly makes sense now. So the nano holds the code to tell what voltage to give out, it gives that voltage signal out digitally to the 4725 which converts that from a digital signal to an analog signal. That voltage then travels through the LM358 where it is boosted? By boosting does that mean same voltage just more amps or power?

Couple of followups,

1 If we supply voltage at this point to tractor does it back feed or cause any issues to tractor switches in cab or on the Can?

2 To make this work do we need to put the hydraulics in float on handle in cab? Or can the cab hydraulics be used at same time as this for manual overide? Would we need to switch this on and off to use cab switches?

Does the timer setting for flow time in cab affect this at all?

- If you vary the swing of voltage does that increase the speed of the hydraulics flow. For example does 1 volt flow faster than 2 volts?

This is very interesting, sorry for so many questions

Cool feature on the JD! Only if they’d provide a digital control as well…

ISObus standard should allow for controlling valves via the Isobus gateway, but currently don’t know of any machine that would support it, so you have to do it the dirty way by hooking into the hydraulics can directly.

Ill try to answer the questions to the best of my ability.

the nano receives the information (from opengrade >100 or <100) to determine direction up or down… the arduino takes the distance from 100 and sends out a pwm signal thats related… as an example if +100 is up and +2.5v is up(assuming) and the deadband is 2.75v then 101 → 2.75v, 120 → 3.5v, 200 ->4.5v (these numbers are all made up to show the interaction)

The greater the voltage the more hydraulics are applied, in much the same way if you just barely touch the lever it will be slow and the more you push it increases up to the flow rate.

The limits (.5v and 4.5v) represent the extremes of the flow rate, which you set in the monitor.

So, the nano sends the pwm signal via I2C connection to the 4725 which is a 12bit DAC (digital to analog converter), the output of that goes to the lm358 as a booster. Basically the only reason I did this was to use the tractors 5v power to supply the energy to send the signal through 3 ft of wire. I was not sure how much amperage was needed, so I took the weight off of the DAC.

Once hooked up, which has to be done with the engine off or it throws codes, the tractor recognizes touchset control is hooked up. The SCV acts normal and can be used in any way until you do a forwared detent. At which point it reads the signal and controls accordingly. One note, on the 9R I tried forward motion is also needed, I can only assume for safety reasons.

There should be no backfeed as this setup was engineered by deere themselves, its basically like feeding information to a nano on a pin to do another operation.

Timer is no existent, only flow rate.

Nut,

Im guessing the reason its not digital is this was designed more for a potentiometer to control depth of tillage machines… and like most Deere things it worked so they decided to run with it for other things (igrade, scraper, etc)… Watching the new scrapers Im guessing iso is used, or will be shortly… Im sure it could be used now but it would take someone smarter than I am at ISO.

Hope this clears up the mud a little bit.

Will this work the same on a Case 4wd tractor? I can’t afford the green ones ![]()

I know case uses the exact same 5v method as long as it’s drive by wire…

DAC 8000 Wired - Manuals has information on where to look, and you will have to get information from your case dealer on how to wire it up.

Well, it’s not really a question of look ahead… it’s more about integral and derivative.

The GPS gives a position only 10 times a second plus some millisecond to do all the calculations, send it to the arduino, do the calculations, send to the valve, make the spool actually move…

So if you only make the valve move according to the offset distance this will happen:

It will just overshot continually over the target because as soon you will have a big correction it will move fast to the line and by the time the spool is at the right spot, after the GPS read it was on target, the blade would already be way over.

@ChrisC thanks for the info for JD SCV control, I will be able to compare directly OpenGrade3D to the Trimble Grading software, on a 450hp 4wd with a 20ft blade! ![]()

@Pat

What kind of analog lever would you recommend for use at input A1? Can you recommend a specific model?

So far I just used this very cheap lever:

It works great for me. Had no time or idea how to build it in the cab so I just hold it in the hand.

PAT i have a question.? what does it mean on github for your 2.1.3 version of open grade when it says “You can now save multiple swaths per field. they are saved in a txt file and a kml file”

It’s for registering your passes, to have a future reference on a computer, like for tile plowing.

It don’t remember exactly now it work!

You have to record your real pass (the green line) and each time you press the save button it save it. It also automatically save the last path(the green line) when beginning a new survey.

Sadly you still cannot go back to an old survey, you still have to create a new field if you dont want to lose your survey.

Im posting a link to a video of building an irrigation pond. Both dozers running open grade. I established an AB line down the center of the dam and used to check the 3 to 1 slope as we built it up. And to find water level as we filled ditches around the sides. and of course for all the terrace work

Also ran into a scenario were i needed a slope i 2 directions. Was grading the gravel base for a concrete parking lot. about the slope about 2 percent lengthwise and also across. So i set up a line running lengthwise at 2 percent but had to fudge it up as i worked across. Not sure if its possible but it is occasionally needed. ![]()

You could use OG3D for that quite easily by exporting a plane tilted in two directions in the optisurface text format. Or any other 3D shape for that matter.

thought about that but havnt looked at that much yet. Is their a way to make a tilted plane without purchasing optisurface?

I was thinking about the same thing with some yard leveling things. Should be pretty doable with a simple python script that dumps out the text file to import to open grade. The absolute height don’t matter that much as you can zero the blade onsite.

Hi I tried to give the slope of 2 degrees on both sides

to a perimeter with the same elevation. With EFT you can give the slope that

wishes.reportOut6415745488661448283.pdf.txt (764.4 KB)

8.agd.txt (2.6 KB)