Thank YOU much! ![]()

When can i (we) expect it?

Add it to the store early next week.

Anyone happen to have a part number for the “old” pressure sensor?

Based on posts it seems to be NC type but I don’t have more details.

(We have an installation and using that sensor would be more convenient that redoing the wiring as the harness was prepared in advance…)

Found it on Telegram but writing it here anyone needs it:

The sensor is a SUCO 166 416 0 31 063 NC

Better use a pressure transducer, it is more reliable and easier to adjust. You only need to connect an additional 5V, you can branch it from the steering angle sensor.

Helping out a friend by transmitting his issue:

So there’s an installation that has the new 3 pin connector. The valve was installed 3 days ago and the tractor was in use so I think not likely there’s a lot of air in the system.

The pressure sensor is normally at 12% when in use, they set it 24% it is able to disengage reliably.

However during autosteer enabled it sometimes suddenly spikes up to 75% disables steering then wiggles there between 75-79% for a minute or so then drops down to 12%.

Any idea what should we check?

It is an LS valve on a New Holland and AIO V4 STD board.

We have magnum with trimble hydraulic valve that was always disengaging. Turned out the steering motor was leaking inside so replaced if and it works again. We watched the voltage on the disengage pressure sensor and we would see voltage spikes just like when you would turn the steering wheel but we hadn’t touched the steering at all.

Hi all,

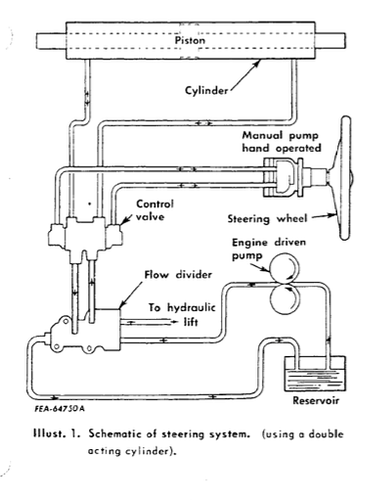

I am planning an auto steer build on an International Harvester 826 and would like to do the steering hydraulically. i have a few questions regarding using this Baraki valve on this tractor. attached is a picture of my factory hydraulic system:

the “Control Valve” in the picture bolts down directly to the tractors body. the oil supply (pressure and return) go through the base of the control valve directly into the tractors body without being visible anywhere. In my picture, they are the lines going down out of the control valve. I know i need access to these two lines, so i could have a spacer plate made to bolt between the control valve and the tractor that would give my the two connections, or, could i eliminate this “control valve” altogether and use the baraki valve instead? I understand the purpose of the “control Valve” to be IH’s way of allowing for manual steering without the tractor running, as well as power steering when the tractor is running. turning the steering wheel builds pressure in the control valve and opens up a valve that allows high pressure oil from tractors pump to flow to the steering wheel and from there to the steering cylinder at the front wheels. if the steering wheel stops turning then there is no pressurized oil allowed past the control valve.

Ok. will the baraki Valve allow manual steering with out the engine running? should i worry about not having steering with out the tractor running? If i remember right the baraki valve does allow for power steering without any of the electronics being connected.

hopefully all that made sense, the bottom line for me is, when i install a baraki valve on this tractor, how had i best install it. If i have to space up the control valve to access my pressure and return oil anyway, am i better to not use the control valve at all, or is there a reason that i need to keep it?

thanks to all of you for the help! if any other pictures or info is helpful i will try to supply it. thanks!

if this question should go somewhere else, go ahead and move it and i will try to categorize better next time. thanks again!

Oh, and I read that there is apparently a website that these baraki valves are being sold on. Could anyone point me to the web address? Maybe i will learn something on there as well.

Very interesting steering system.

If the flow divider divides the flow from the pump into 2 streams with a constant flow ratio, e.g. 50%/50%, my standard OC valve connected in series between the flow divider and the control valve will work. I think that all manual steering functions will be retained when the AS valve is not used.

Yes. I was thinking about what could be the reason. The pressure sensor in the Ls block is mounted on the Ls port which connects to the Ls orbitrol. The pressure on the sensor can only be increased from the orbitrol side.

Hey, I installed a OC valve on an T7040. It works very well, but today I had one problem:

I started the tractor with the AOG main switch off to drive out off the machine shed. After about 30 minutes I started the traktor again with AOG main switch off und i was not able to steer. The steering wheel wheee locked. After turned on main and actived autosteer. I deactived it and now I was able to turn the wheel.

What could be the problem? The main switch switches the power supply of the Kaupoi PCB and the cable to the activation coils of the valve.

I think the problem must be in the valve?!?

Trying to steer feels like steering without the motor is running

It seems that the pump is a bit worn and has problems with sucking oil when it goes back into the gearbox and the pump is dry. This can be solved by adding a non-return valve after the pump, which will prevent oil from flowing back and prevent air from entering the pump. All hydraulic standards recommend the installation of non-return valves, I don’t know why CNH doesn’t do it at the factory.

Curious if anyone knows which valve I should buy for the following equipment

Case IH 9270 4WD

Case IH STX440 Quad Trac

and a

New holland CR9070

I’m Assuming I need the LS valve but there is a 30L and a 60L option for the shutoff valve flow.

From what i read in the service manual for these tractors, I dont think the flow divider is really a very functional part of the steering system except for insuring that the steering system always gets 3gpm of oil. consequently, i am not sure why a 50/50 flow ratio would matter at that point. maybe I am missing somthing.

If i eliminate the control valve altogether, and put the baraki valve in its place, running lines to the steering wheel, the steering cylinder and oil supply and return, is that going to work, or do i need to keep that control valve in the circuit?

thanks again, there is no way i would be able to begin this project without the great help here!

But it worked very well for about 6 months without this problem

I think that over the course of 6 months the pump has become a bit worn out and is unable to push a few bars of air through the compensator valve. Add a linear check valve after the pump and the problem will be solved.

When i drove out of the shed it worked and half an hour letter there‘s air in the pump?

It seems strange but i think ypur theory could be true.

Can I add this check valve befor the P goes into the valve?

Or should this non retourn valve direct after the pump?