Do you have the diode show here?

No I do not. But I ordered a relay module with a diode on it that I though might do the job… I’ll add one.

I am replying to my last post in an attempt to make the multiple conversations here more understandable.

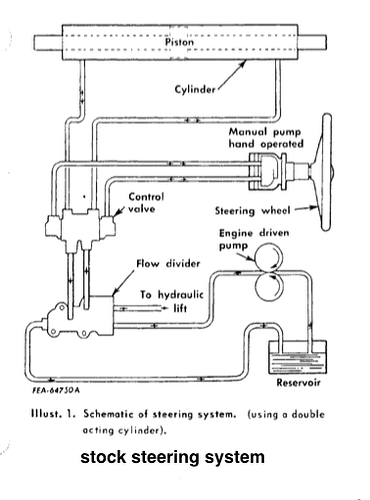

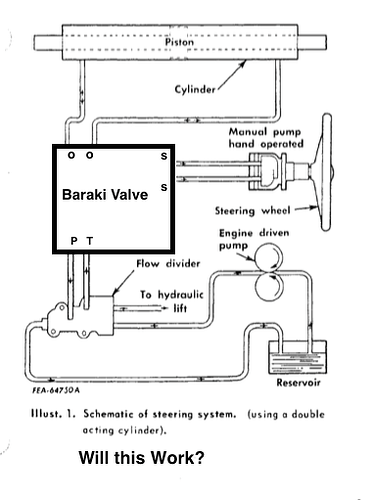

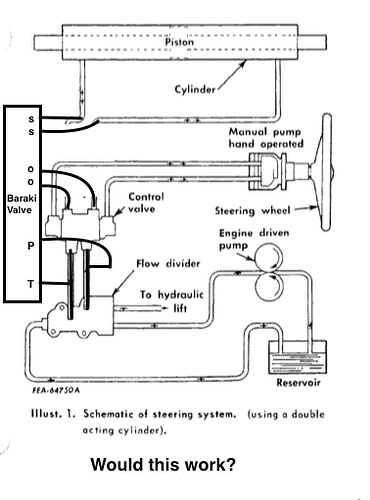

I made a couple of diagrams to make my questions more understandable:

How had i best use a baraki valve in my steering system? can i eliminate the control valve altogether like this next picture and use a baraki valve instead?

Or, do i need to leave that control valve in the circuit, and in that case, would this diagram work?

thanks again to all the help here!

~IHTractor

After 3 tractors I can safely say that this new pressure sensor is not good.

We have a tractor where it suddlenly stuck at 78%. (i.e. max range)

Now we have a tractor where it overheats the 5V converter of WAS (with 13mA that shouldn’t be possible) so kind of acts like a short circuit.

There’s a tractor where the voltage doesn’t go up/down when we turn the wheel.

Is there anyone with this new 0.5-4.5V output sensor where it works as expected? Is it just bad luck on our side?

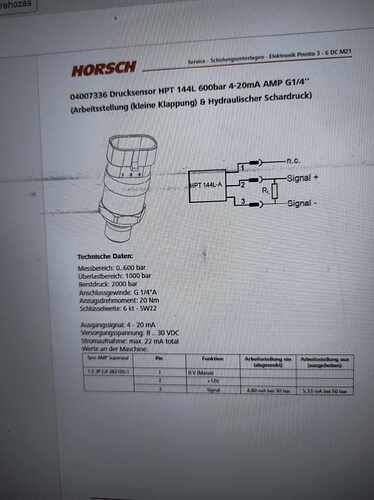

We also tried to use a Horsch sensor wired as in the table but get 0% on screen?

Did anyone try to use something similar for disengage?

Have you tried to measure continuity from sensor input to the pins at pressure/0 to20 ma

Did you try to wire a potentiometer to simulate the sensor ?

Not yet as I’m still far away from both tractors and PCB. Hopefully in december.

@baraki we’d have a doubt here, hopefully you can answer.

Some guys ordered 30L OC valves for new holland TM.

not sure what @Stummer ordered for his Fiatagri 180/90 but I suspect it’s also 30L.

After looking at the drawings it seems that the difference is in the 2 lock valves. Using a 30L instead of 60L could result in slightly heaver steering? (As the oil can’t escape fast enough)

Is there a good way to check what valves do we need?

Check pump size?

Check orbitrol size?

Other than the lock valves to enable steering is there any difference?

We might need an extra 4-5 valves of 60L as the guys I spoke with said that they’ll install the 30L valves on their other tractors.

Could a 30L instead of a 60L cause problems with the steering pumps?

Any side effects if 60L is used instead of 30L?

Can we do some sort of explanation/guide for the wiki/webshop for valve sizing?

Unfortunately saying that for big tractors you’ll need 60L is not that adequate as it really depends on brand. 130-170 HP tractors can use 30 / 60 depending on the brand. (80-150 → likely 30L but 130-200 likely 60L but quadtrac with 350hp++ needs 90L)

Cheers

A 180hp 8200 and a 8670 Genisus super steer works great with the 13L Hydra force SP10-58C.

I believe so, a small proportional valve is good at finetuning around straight ahead. In the OC systems the important part is the bypass/relief valve as it must handle all the oil from pump. Also the cut off valves must be able to handle the maximum flow needed to steer from left to right (as mentioned above could make it harder to steer manually )

I believe the 60 I pump is needed on heavy tractors especially at low engine rpm. You can measure the cylinder/s to find out how many liters is needed to steer from left to right. If you normally can steer all the way in 6 seconds, then multiply the amount found in liters by 10, and you know how many liters flow through the lock valves per minute.

If orbitrol capacity 160ccm , 1 liter = 1000ccm

if max speed 1 sec/ 1turn , 160*60 = 9600ccm or 9.6 liter/min

if orbitrol 250 ccm , 250*60 = 15000ccm or 15 l/min

but speed of turning orbitrol 1sec/1 turn are not realistic , probably max half , 30 turn/min

Any luck making a couple 90L for me? I dont see it in the store yet.

If you know the type of orbitrol you can easily calculate whether the shut-off valves have sufficient flow. The method provided by Grabik is very good.

The 30L valve will be good for most tractors.

E.g. in NEW HOLLAND

T6050, T6060, T6070, T6080, T6090

T7030, T7040, T7050, T7060, TM

CASE

Puma165, Puma180, Puma195, Puma210

We can find orbitrol OC (without Ls) with a capacity per revolution of 160 - 220 cm3 (depending on the model), the maximum flow according ( for 220cm3) to the manufacturer’s data is 26 L, but this is a purely theoretical capacity, in practice, to achieve 26 L flow on the L and R ports, you would need to make 2 full turns of the steering wheel in 1 second ( 120x0.22=26.4). Is someone turning the wheel that fast?

In practice, 1 revolution per second will be a very fast steering, which gives 13L/min and I think this is the maximum flow that occurs in practice.

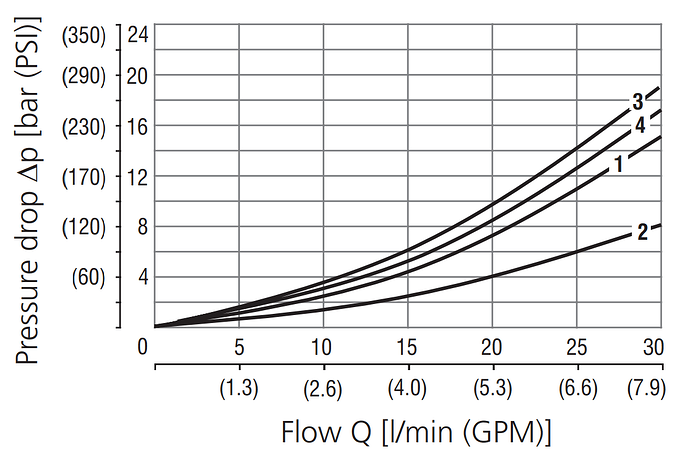

I am attaching a flow chart for 3/2 30L shut-off valves.

Line 1 and 2 are for ports that are connected during manual routing. So for 13L the pressure difference is about 4 bar, taking into account that the overflow valve should be set at 170 bar the effect is relatively small.

According to the catalog data, the pump can generate 210 bar during continuous operation. The maximum pressure of the orbitrol is 170 bar, so we have 40 bar of reserve.

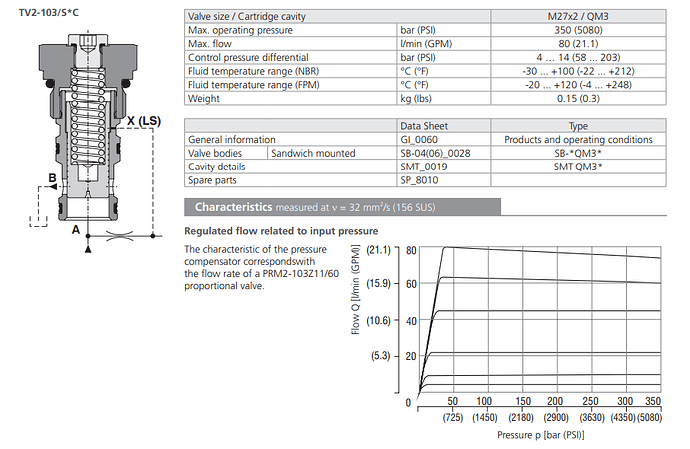

The 3-way compensator that manages the flow from the pump has a maximum flow of 80 l, so it is completely sufficient for a pump with a maximum capacity of 60 l. Below is a graph of pressure depending on flow.

For 60L it is 25 bars according to the data. But it doesn’t matter to the amount and pressure that the orbitrol receives, all the oil that the pump pumps goes through the block and goes to the orbitrol.

Thank you!

So for ~200cc orbitrol the 30L valve is fine.

Over 200cc better to use 60L.

And over ???cc better to ask for 90L ?

Do you think this could be documented on wiki too?

(I think it is best to mark the tractor type when ordering.)

I think you could add this information to the wiki.

I will also make a list of tractor models that have been tested with a given type of block and work well.

Hello

I need a steering valve for a John Deere 4755 tractor. @baraki said awhile ago that he had a steering valve for a 4xxx tractor. I can’t find this valve in the store. Am I looking in the wrong place, or what? Does anyone know how I can order such a valve? Thanks

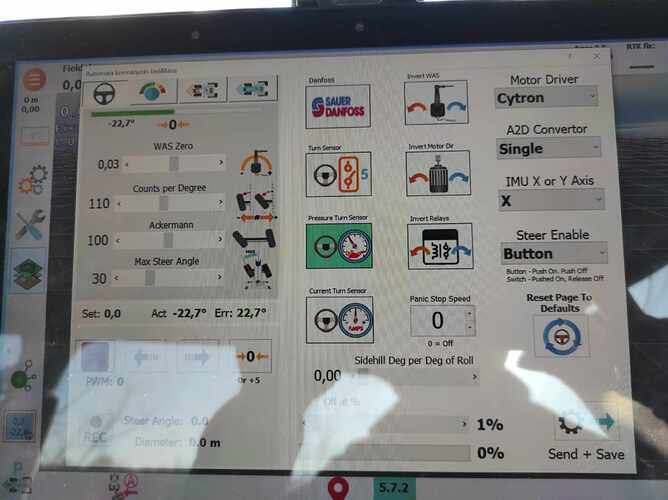

Hello, can the new pressure sensor be implemented the same as the old switch? I use Kaupoi v4 and i am unsure how to connect it on the pcb… does it belong to analog in now? or still remote?

Analog in A0, there is a pin on the PCB for this Nano pin A0.

Then use “pressure sensor” in AOG settings rather than turn sensor