hey Baraki i have bougt one of your hydraulic steering block together with Lars Vestergaard. I have to mount it on a 2007 Case Puma 210 and i would like to see your video can make it public ? now i cant see it because its private.

I have Valtra T190, so I guess it is closed LS steering. How much for the valve for it? Do I only need to add hoses to make it work, do you have instructions how to install it?

Yes, only snakes are needed. The valve block has all the necessary valves and a pressure sensor built in.

Connecting is very easy, I will help you at every stage.

Hey, baraki i send your email about hydraulic valve assembly i would like to buy one for my n141 ls.

(Attachment 20221029_153658.jpg is missing)

Hi @baraki , do you have a regulator to adjust the speed at which the cylinders turn? As it manages to adjust the speed at which the wheels turn, I understand that all the input pressure from the orbitrol is transmitted to the steering cylinder. So do the wheels turn sharply or am I wrong?

These are proportional valves, they set the flow in proportion to the PWM value applied to the coils. The valve for the OC system has a built-in load sensing system which redirects only as much oil to the proportional valve as needed at any given time, the rest of the oil flows on to the orbitrol. It works very smoothly and accurately, you can turn the wheels for fractions of a degree.

Thank you very much for the clarification. So the output signal from the Cytron is already the correct one for the PWM proportional valves?

Yes. Just plug it into the citron. A relay / mosfet is also required to activate the shut-off valves.

Would you be so kind as to tell me which model of mosfet I should buy. Do you have any wiring diagram so that I can get an idea.

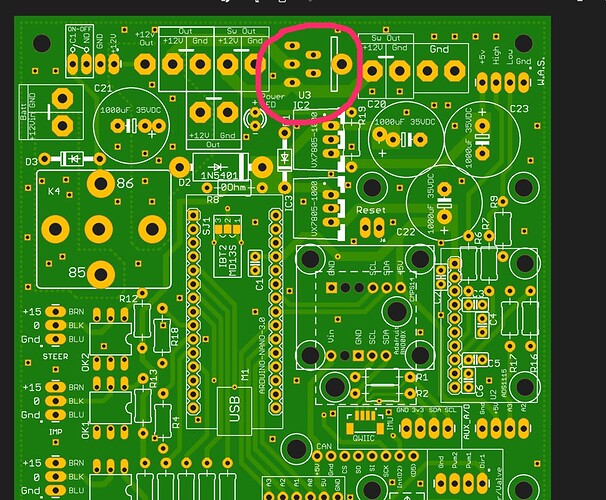

What kind of PCB are you using

La PCB Kaoupoi 4.1

If you soldered all the components that were in the project then you have a mosfet to activate the valves on the board, just connect the cables.

Option to use a pressure transducer to use the full shutoff function in AOG? That would be better ![]()

This is the standard on my every block.

I know that, but we worked out on AOG to work with a pressure transducer 4-20mA. So you can set the pressure kickoff in the software

Yes, I know, but the converters are much more expensive than the pressure switches. The sensors I use are adjustable with a screwdriver so you can easily set your preferred pressure. In practice, the system works well over a very wide pressure range, you don’t need to calibrate it in any particular way.

Of course, if someone wishes, I can mount the transducer.