many thanks, but i am looking for the standard version.

The V4.1 standard has yet to be released. Probably will be released sometime soon

I was reading into everything the last days and would like to have a panda-localization setup (teensy4.1, F9P, BNO, connected over ethernet to Tablet) seperate from the AIO board (WAS interface, motor controller, …) and connect both over eth UDP to the tablet. It seems for this I would have to run a second teensy on the AIO board and split up the .ino into the localization part and the rest… are there ressources explaining this setup that is presented in multiple youtube videos e.g. the ones by potatoFarmer?

now after reading about upcoming v4 standard board i’m not so sure… wherther I should stick with my plan

If you are wanting modular, i would visit with @PotatoFarmer

If you are wanting to go with a compact board to do only steering and maybe section control, I would stay with the AIO.

The standard AIO is getting close to release. Some minor changes are being made.

there’s also a 20amp version of that instead of the default 5A so you’d maybe need to set the current turn % to 15% (3A) instead of 60% in AgOpenGPS.

I’ve started to buy the parts needed to buitld the V4.1 micro PCB, i’m still very new to all this but got a question about the V4.1

While investigation this forum i read that the V2 needed a ADS1115 to convert the analog WAS signal to digital to improve speed of the system.

on the V4 there isn’t a ADS1115 anymore, i read that this summer the teensy will be tested for use without a converter, but in the meantime, before this RVC update is finished what part will do the analog to digital conversion?

The V4.1 has the ads115 on the board like most of the previous designs. The only reason it has the headers is because occasionally there are supply issues and you need to buy the adafruit board. When you go to order at JLC they should tell you if they are placing the smd ads1115z

sorry completely missed it on the board setup! ![]()

one more thing to order then for me!

Great work on this guys! I am wondering if there is a guide on the comparison of Standard vs. Micro PCB? Just trying to decide whether to go for Micro now or wait off for Standard.

Hi

I think I have assembled all the components necessary for the autoguiding.

Is there anything else to solder like wires among other things.

where do you need to put jumpers to use a 24v motor?

Thanks

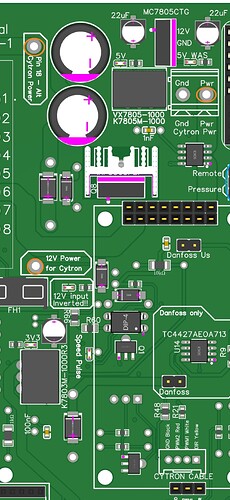

Have you powered it up without expensive parts installed to verify voltages first? Use the test points by the IMU.

You’ll obviously need the fuse installed.

How are you powering the Cytron and what is it controlling?

You don’t need the ADS module as you already have a surface mount one (just below it).

You need to solder a wire from one of the orange points (depending on what power input pin you use in the ampseal) to the pwr input of the cytron

Does the standard AIO fit in the same aluminum enclosure as the old dual board. I am thinking I might switch and make adapter cables for the installs I already have. I probably will leave the ones I already have alone and do new ones with the AIO standard or micro.

As for CAN there are pins available in the amp seal for this a single CAN bus, right? If I want additional CAN then I would need another teensy and a CAN specific board. I am not sure where I am heading with this at this point. The current dual boards are working well. Planting is finished so now we have time to tinker again and wait for the crops to grow.

The enclosures for standard and micro are still the same.

Ther is just one can on the amp connector for v4.

When I was using the standard, I just bought some sma shorties with a 90 degree end. I used hot glue secure the board to the end of the box. With the screw spports in the amp, I dont think that is needed.

I only went to the micro for the reduced box size. It is easier to find a place to mount

Both boards have nearly the same schematic and parts list, so preference is the biggest difference in choice.

Keya autosteer motor with built-in driver for precision agriculture AgOpenGPS. We already have end user in Europe who’s using this motor with AgOpenGPS on Valtra T171 tractor. See below link.

well I followed your advice and after testing the different voltage points I noted these values

Micro ardusimple 3.3v

teensy 5v

ads 1115 8v

micro and teensy , i think its the right voltage.

on the other hand the ADS1115 I should have 5v instead of 8v, why I have 8v?

Sometimes(from my experience) I noticed higher voltage outputs when there’s no load. As soon as you connect something(try a light bulb or smth and than measure voltage as its lighting) it drops back to normal. I assume its faulty capacitor or… who knows I would love to know also.

That’s not normal.

Is it a v4.1 with all regulators mounted by JLCpcb?

no, when I ordered on JLCPCB there was no stock for the MC7805CTG

I ordered it on the TME website and I soldered it myself.