It already has. If you can feed your harvest rate into the arduino. We can map it.

We already can import kml files. Send me one and I’ll see what I can do.

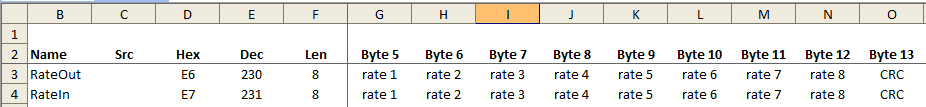

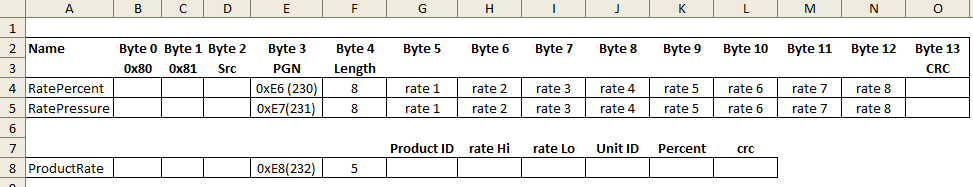

Byte 10 could be used for a second product. Then 2 products could be applied at different variable rates. May not be necessary.

ezio-2021-10-06.kml (13.4 KB)

the shape file is not authorized

Reading from the load cell connected to the chain tensioner of the grain feeder multiplied by the driving speed?

These are the files that agleader’s sms software makes.

https://drive.google.com/folderview?id=1EO8sIvWHHEObwvi6lO4PqhglrVNMN6WK

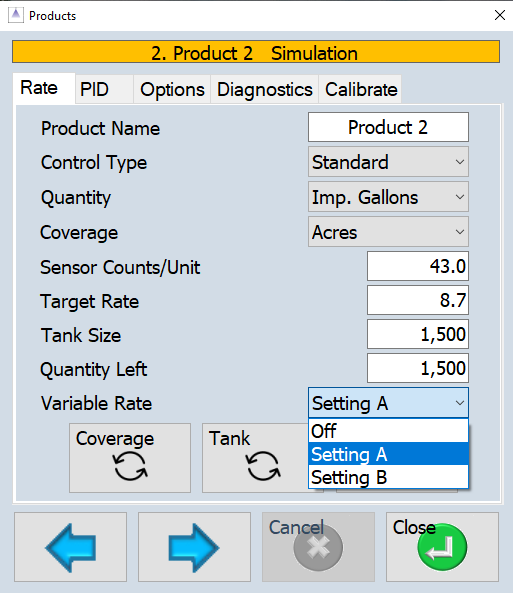

To implement it in the RC app I added a combobox for variable rate:

Setting A would the percentage from byte 9 of the machineData pgn and setting B would be from byte 10. RC would take the initial target rate and multiply by the selected percentage before sending it to the arduino. As the percentage changed across the field the variable rate target sent to the arduino would change.

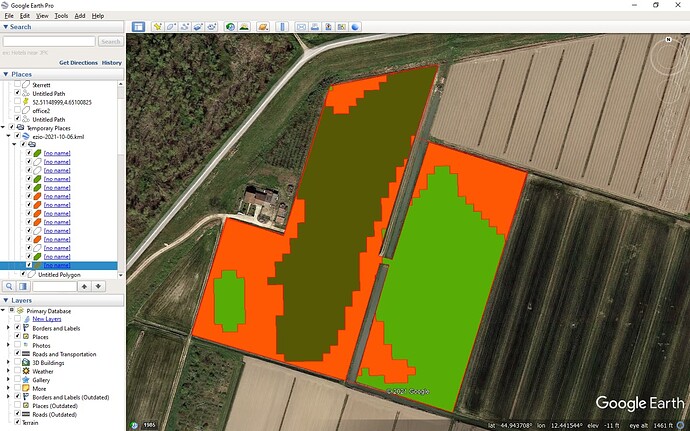

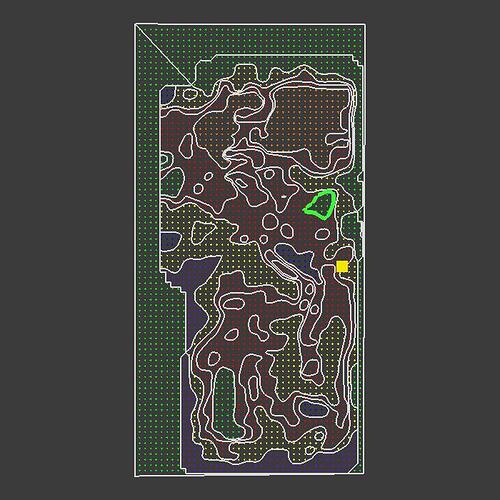

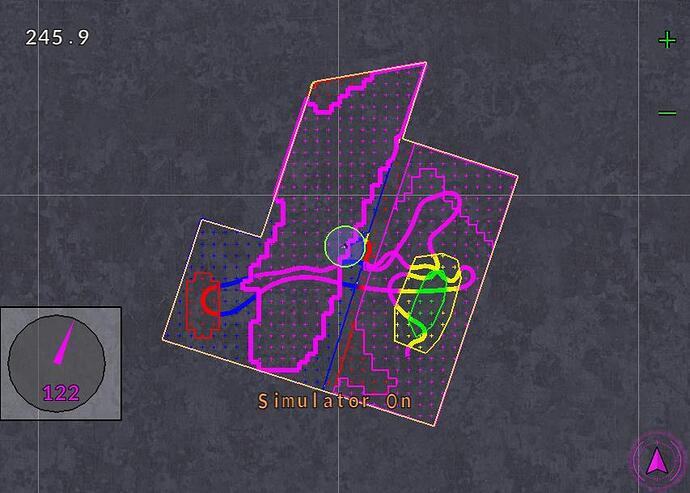

I opened the kml file that you sent. I edited the properties to show it filled.

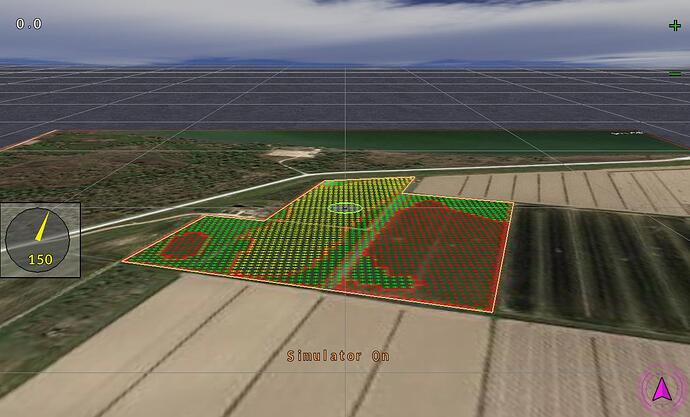

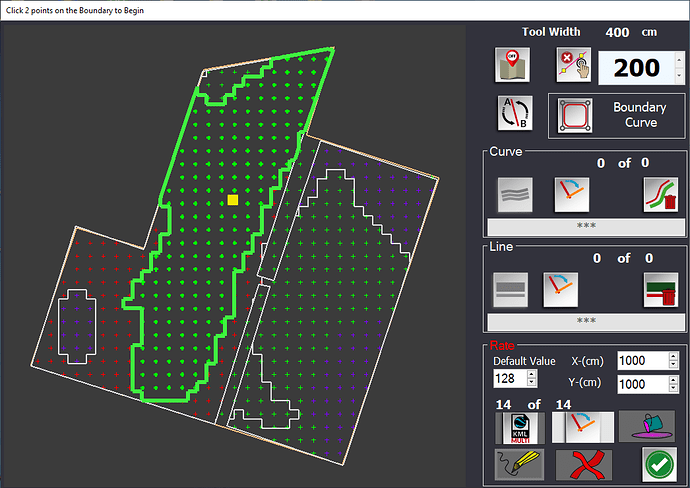

I made boundary around whole field in GE and saved it to a kml. Also saved the three predominate centers as kml. I then imported outer boundary into AOG. Then the three inner. Then applied the points and then edited the ones that needed to be different by tracing the kml lines. It is a work around right now but proves the concept.

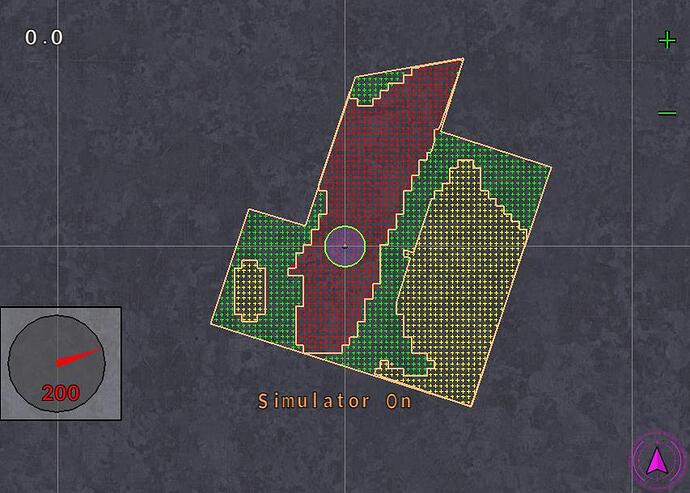

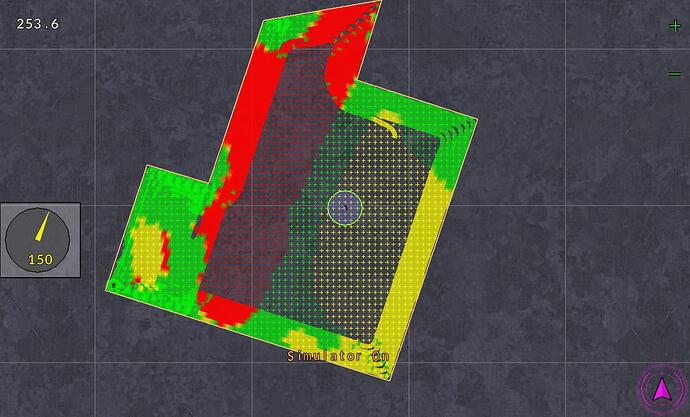

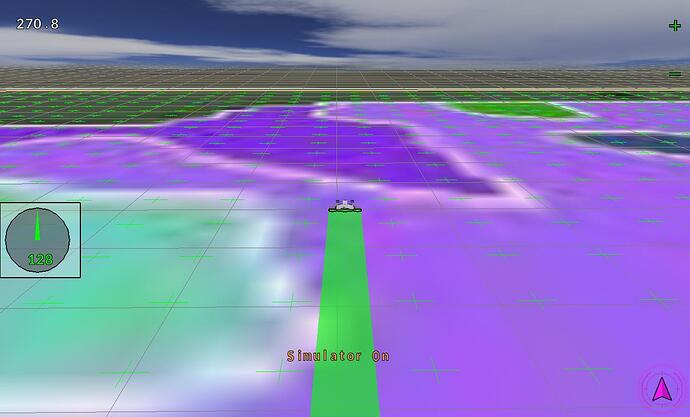

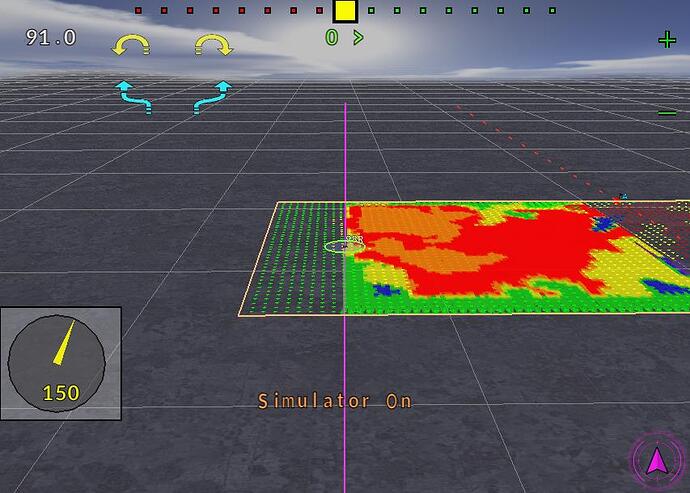

This is it as it has started running an ABLine then a few passes on the boundary curve. The 150 is just a value I put in there to show the color contrast.

Just for the question, Could we not have a full pgn with nothing but rate out and rate in. 8 chemicals out and feedback of the 8 chemicals in.

We mix various chemicals ahead of time. But could you not add inline valves and mixers? More chemical, less water or more water and less chemical? This may be how the bigger rigs operate. I can just say we would benefit from keeping it all separate.

I like. I would send in and out in 0 to 200. That way you can compare maps.

With the background. Gives you places to trace, but not reading the values.

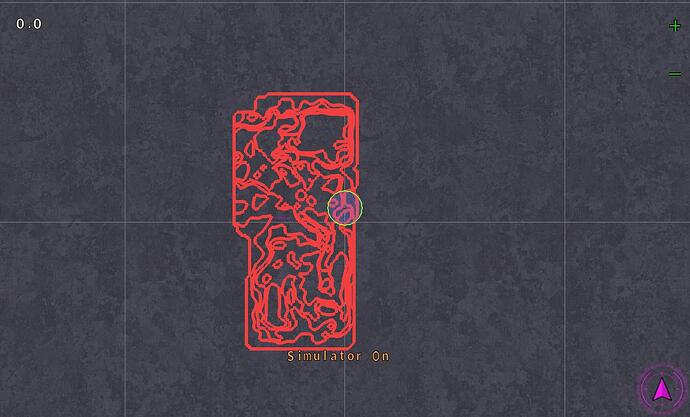

Yes, if you want to. This one is off center. I could not cut it correct because the earth is not flat. May need to reduce the size of the cut box or allow a shift. You still need to trace this as it does not pick up the pixels.

No words to describe you work. Nice!

Thank you. Brian had most of this in the software at one time or another. I copy and paste well.

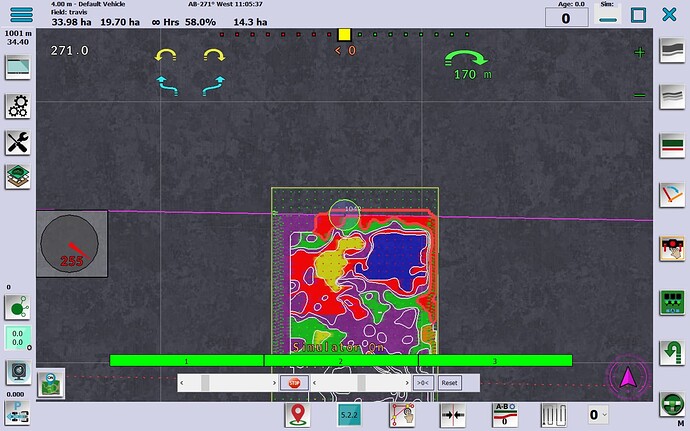

This I simply converted the shapefile to kml in GE and asked AOG to import as multi kml boundary. Never thought it would do this as easy as it did. This file has rates and such attached. I think that we can look for what loop we are in an provide the rate automatic. I will give it a try later.

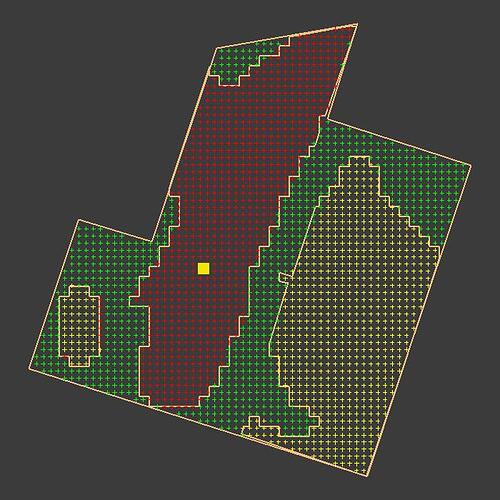

Alright, it will import the kml into the ABDraw. Not as a boundary but as a rate area.

You can cycle through each and apply the value to all points inside the boundary. Found a little problem. The cross shaped area on the lower left is inside a larger boundary. You must rate the outer boundary before you can rate the inner boundary.

It would be nice to have the absolute value in the first bytes (e.g. 2 byte Half-precision floating-point ) and the unit (e.g. 1 == kg/ha, 2 == liter/ha, … 255) followed by the rate in percents as described by SK21 in the tab.

(Some more thoughts in Additional selectable PGNs for multiple purposes)

Big changes to the VR. Once it loads the multi kml, you simply scroll through them and set the rates. It no longer looks for the mapping points. It finds the rate contour you are in and sets the rate to that value. I’ll probably add back the draw contour line feature. The big hurdle was what to do with contours inside of contours? Sort them by area smallest to largest. Look for the smallest first, when you found it you have found the correct one. No need in looking in the larger lines. This was a big step forward. I don’t know why I didn’t think of it earlier.

Practically this PGN is sent by AoG to the Rate Controller, in which the conversion parameters from percentage to quantity are then set and then sent to the Arduino which controls the valves or the opening of the fertilizer spreader?

Yes that is the idea.

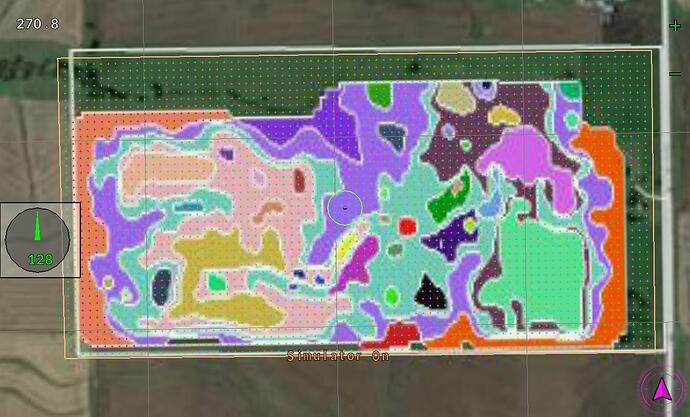

Rewrote most of the color routines. It now takes the max and min rate and colors based on the delta between the two. So if the range is only a few points, it still maps at the entire color range. All the mapping and rate is done from the polygons not the points.

If you have a kml, import it first. Then you can draw other rate areas. All the rate boundaries are created at the rate value in the box. Then you edit them by scrolling through them. All done by percentages. A simple spreadsheet could be created or even an on screen calculator to convert the rates to percent. 3000 is base line 100 percent, 3300 is 110 percent. 2900 is 97 percent. etc.

Next I’ll build the dedicated rate byte string for communication. And the ability to save the rate boundaries to the field. Wondering if we can edit them inside of AOG?? I know we can draw new ones. But can we edit them?? I have to work on deleting them as well. Duplicate polygons drawn over the ones below does not work very well.

Here are a few screenshots: Note the polygon is drawn to the rate you are in.

It will be good to see it in action. Better to understand it then.