I see the problem. It’s not actually a zip file but a rar archive. Change the extension to rar, @Dfarms11, and then you’ll need a rar extractor program to open it. Probably if you used a normal zip file it would work easier for others.

thanks, I’ll try now

files.zip (51.9 КБ) Is it open now?

Perfect. Thanks!

Should probably mention that cover is for a Deutsch plug, not an Amp seal! Went and printed it and it don’t fit! Lol

This is my biggest PETG failure method also. Blobs fall off and then the printer loses steps when it hits the blob, usually during a rapid mode. Turning down the rapid speed and enabling Z hop helps to band-aid the problem.

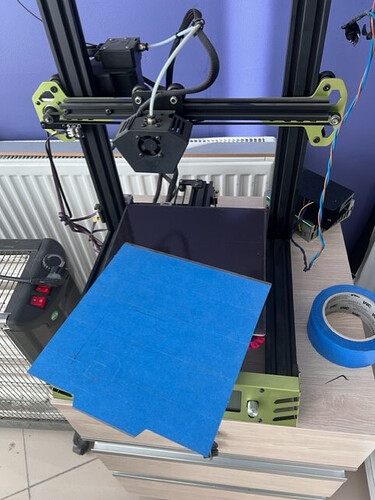

Looking to buy a 3d printer for a few things including making a box for aog, is it worth the extra to have a direct drive head over one with a Bowden tube?

Yes it most definitely is. Can you make a Bowden drive work just fine. Yes many people have. Some may even prefer them I don’t know. But a direct drive is easier to pull out of the box and just start printing. TPU included.

My 2 cents worth I had never seen a 3d printer run until I bought one. I got a sovol sv06 from amazon ive had a few issues but they have a great support group on facebook. Ive printed the 3 piece gears the motor holder quick attach end small gear the tpu worked great, I was worried it would give trouble, worked good.

If you can build aog you can figure a printer out, Im proof.

Maybe you have a 3D file for this project?

hello here is the file. https://discourse.agopengps.com/uploads/short-url/33uPYZQPDEIkOpUnRggTSFqbskz.zip

I have an ender 5 plus. Wich is bowden tube. I hav thought about converting it to direct drive. but decided against it for now.

Both have pros and cons. I have not printed TPU yet so cannot say anything about that.

To update this topic, I bought an ender 3 S1 plus. Only done a few prints, but pleased so far

I’ve been successfully printing TPU with my Ender 3 and bowden tube. I printed a mount plate for the extruder that has less gap between the tube entrance and the gears, which keeps the tpu from making a bird’s nest. Print slow, no more than 30-40 mm/second. I’ve tried various retract settings from nearly nothing to 7 mm, and they all seem to work for me. Have had pretty good results.

A direct drive would allow faster prints, no doubt about it.

You have to be careful with direct drive on ender 3’s. Depending on how you set up the direct drive you can run into issues with the gantry arm sagging from the added weight causing it to collide with the print. I heard that adding a second z screw can help but I just got pissed off and bought a better printer.

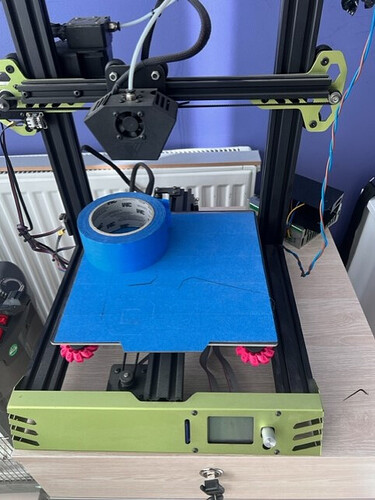

So I’ve got a Ender 3 S1. It has the direct drive extruded on it. What setting you guys using to print PETG? I just have not been able to anything to work properly.

Sometimes ringing around corners, occasionally warping, and just haven’t been able to get all the dots connected at the same time.

On my bowden tube ender 3, I use nearly the same settings as PLA for speed and retraction, except I run the hot end at 240 and the bed at 80 C.

I get some ringing, as is often the case with a bed slinger. But no warping issues. I have some problems getting the PETG to stay stuck to the bed. I had been using a glass bed with tape on it, but painters tape has some kind of coating on it and the PETG does not stick to it. Right now I’m using a Garolite bed, which I have to scuff up with a scouring pad, but seems to stick okay and always releases.

Direct drive extruders are always heavier than the bowden tube ones, so you will get more ringing. Without a 32-bit main board and a motion sensor to measure ringing, and a firmware that implements input shaping, there’s not much you can do about ringing other than to slow down the printer.

This does a good job. 3M

So you just put this on your building plate?

With the stock ender 3 bed I actually had problems with to much adhesion. Removing prints actually ripped prices out of the bed. I am using a textured PEI bed now and it works amazingly well. I would absolutely recommend the upgrade.