20 hrs? That’s good going!

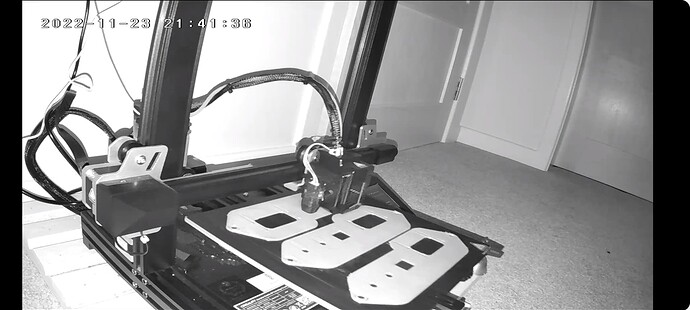

Pretty impressed with the Bambu Labs X1C, just toss filament in and go.

What model want you?

If you can export the step files for the micro in the snap and screw type with one and two GPS that would be great. I don’t think it’ll make that much difference print quality wise but I’m keen to compare if you don’t mind.

With Cura i can change any print setting in stl file

I make step files, and i will post here url to download it

STEP files are also easier to remix and modify with parametric tools since they are “solid”. Also the curved surfaces stay curved, whereas in the STL they become faceted, which makes modifying the model a bit more computationally intensive with all the triangles.

No warpage or shrinking on such a flat part very impressive.

These cheap-crap Amazon cameras are superb! This is in a pitch dark room! I don’t have to leave the sofa! ![]()

PETG working nicely now at much lower temps than they should be. This is on an ender 3 V2 neo.

which camera are you using? Does it have IR lights on the front of it?

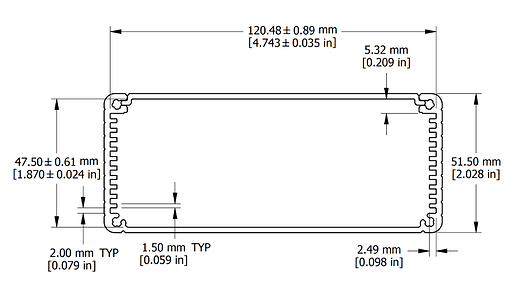

@Vili do you have a 3D CAD (.step for example) model of the assembled PCB V2.4 Standard with Ampseal connector?

I would like to design custom end plates for a hammond box (1455Q2201BK seems to fit, see drawing below). In order to draw the holes in the right place, it would be great to have a 3D CAD model of the assembled board. I was not able to extract such a model from easyEDA. When I export a 3D model from easyEDA, it is not to scale.

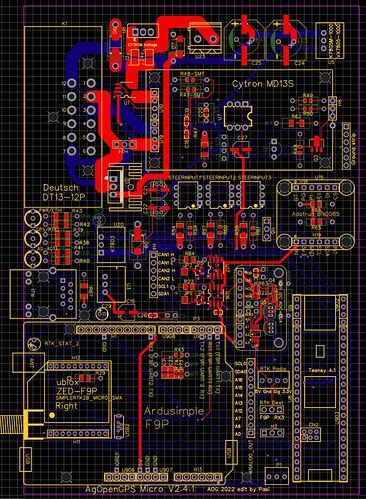

I edited for myself. Micro and Deutsch. Short 4mm copper +12V_in, Lock, Right, Left etc… One normal F9P or ZED-F9P. I hope I did it right and it works.

Looks good. That is similar to what we are doing with the all in one boards.

I would put the xbee socket back on the board though. If you run a micro, and want to use radio corrections, you won’t be able to very easy.

Hello,

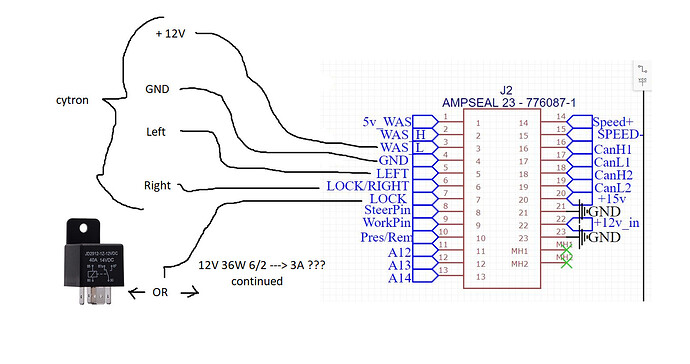

I received my standard f9p pcbs with ampseal 23 and I’m starting to look at how I’m going to make the modification for the high power part.

In order to keep the stability of the cytron I still think of soldering the pins on the power input and output side in addition to the two screw terminals.

From my observations this should pose no problem since I keep the same pin on the ampseal.?

For my 6/2 valve which consumes 36w under 12v so 3A wouldn’t it be wiser to connect a standard 12v 40A relay between the lock output and the valve.?

Thanks

Good idea keeps min amps on the board

Unfortunately PWM2 triggers “lock” often around 0 %, thats the reason why a Mosfet is used.

Or better adjust code and use A14 as 5v output when engage button is pushed

Hello, thank you.

The idea of the 12v automotive relay reassures me more than using a “Chinese” 5v relay as can be used with the Arduino for example. These 12v relays are reliable and proven for many years. ![]()

I don’t quite understand the story of the lock around 0%… ![]()

![]()

![]()

![]()

The butt is not to bypass the MOSFET using the PWM2 output to directly power the 12v relay BUT to use the MOSFET output to operate the relay.

My knowledge of electronics is limited but for me that the MOSFET directly powers my 6/2 valve or powers the relay coil which powers my 6/2 with a 12v power supply directly from the battery does not change much in the operation of the MOSFET Nope.?

In addition, with less power going through the MOSFET, there should be less heat to dissipate, right?