Afternoon all

Another day, another CVX… but this time over CANBUS. Went out fully expecting to find the usual autosteer valve, but it had what I think is a Danfoss instead. I knew there was Danfoss documented in the wiki, but I thought I’d connect the CANBUS board (CommonRail’s design) I had with me instead, just out of interest.

With CAN3 connected to the green socket behind the seat, lo and behold, AOG is reading the wheel angle sensor and the wheel turns! Well, that was unexpected as I’d never had any luck with a CVX over CANBUS yet (and I know why, they had valves with Trimble autosteer modules already fitted, that were driving the valves over PWM).

So, this could be nice and easy… Per CommonRail’s guide, I needed:

CAN1-H = Pin C Diagnostic connector right rear pillar

CAN1-L = Pin D Diagnostic connector right rear pillar

CAN3-H = Pin H Diagnostic connector behind seat

CAN3-L = Pin J Diagnostic connector behind seat

Used my Flashing tool to download CommonRail’s CANBUS code to the Teensy: Releases · lansalot/AOGTeensyFlasher · GitHub

Went into the Service Menu in it and set it to 2 (For CaseNH) and P for 460800 serial.

So I wired them up, and couldn’t get the steering to engage. Nothing doing. Also, after a while, the tractor started throwing steering codes on the pillar, most notably code 15327.

Super-helpful guys on Telegram pointed out that I would need to go into the tractor’s own diagnostic menu and enable autosteer, so I bridge pins B and G on the diagnostic controller on the pillar (NOT the green one behind the seat) and turned the ignition on. I then went to U1/H1 and ran through the WAS calibration process (this is what 15327 means, basically that the WAS hasn’t been calibrated). This procedure was a bit fiddly to get going, especially the spool calibration, but the details are in the attached PDFs.

NH Steering Cal.pdf (4.0 MB)

New Holland H3 Config.pdf (1.7 MB)

I then went to U1/H3 and set “ch2” (navigation controller present) to “YES” and I was then able to engage steering !

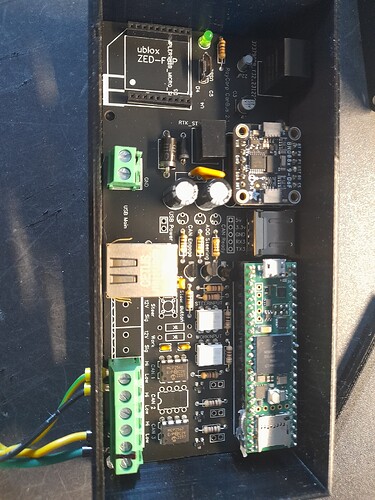

And my custom case fits nicely in the usual place next to rear window, so nothing extra in the cab to annoy the operator.

All pretty easy in the end! Shame I didn’t notice my phone had focussed on the wiper instead of the stubble until the end… doh!