So you can use an open center valve on a closed center system?

The steering circuit/hand pump is open center on the 88’s, therefore you need the open center valve

Today I received a shipment of valve parts, so we are packing and sending all outstanding orders.

Has anyone installed a barki valve in a 80 series fiat? Is it open center? any photo of the installation? thank you.

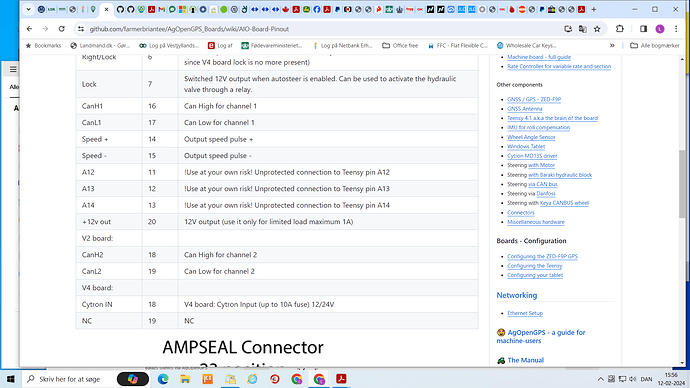

Where does pin 18 go to?

Hi Baraki,

Just checking if you sent the valve, you mentioned that you missed sending it and were sending it 11 days ago but I never got a tracking number can you please update me, thanks

Is pin 18 a live feed? the diagram shows it going to the 2 pin, I have the 3 pin purple plug which is wired to pin 10, have everything else wired in & have pin 18 & nowhere to go with it.

Just to get the was sorted now.

were you able to get a 90L shutoff for my Case Quadtrac?

I havent seen it in your store yet

would a 60L be sufficient for a 4WD case with tires? Or should I wait for a 90L For my Case IH 9270

If you’re using an AIO 4.1 or later, pin 18 is power into the Cytron that provides power for the Valve.

Some people use the 12v in on pin 22 to also power the valve, although then there is no means of isolating the valve power independent of the PCB.

The terminology passes me by unfortunately.

So in terms of powering the valve, you mean through the relay? I’ve it powered separately from a 12volt supply with a switch for isolation.

When all is powered up there is no power at pin 18.

What people are saying is pin 18 is an input that you can put 12v or 24 V on. and from 18 it goes to the cytron. 18 is the power supply to cytron, especially when using 24 V and/or high current needed for electric motors to turn steering wheel.

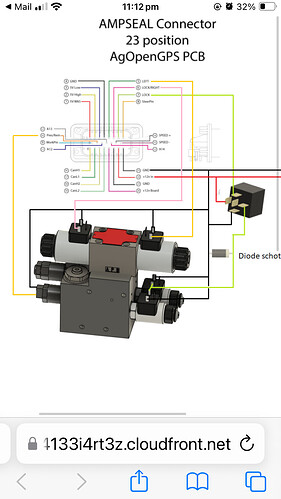

But make a drawing/schematic of your wiring, then we maybe understand your problem. As you could be wiring it differently than the link to wiki in post 753 suggests.

If you check more on the wiki, you can find info about pin 18 (on can boards 18 is used for CanH2) Because can boards do not use a cytron.

If you scroll down in this link you see more wiring diagrams.

I have a baraki valve wired up as per the drawing, except I have the 3 pin transducer i think it’s called, I have a 5 volt reducer going to

pin 3 on the purple plug

Pin 2 to earth

Pin 1 going back to the PCB to pin 10

The diagram shows the relay feeding off the main input live feed for the PCB, but I have a separate feed for it with a kill switch fitted in the line.

Pin 8 I have going to a momentary switch and back to earth, other than that it’s as the diagram

I’m not trying to get it working yet as still getting the was fitted but as yet nothing is connected to pin 18, should it have 12 volts feeding into the PCB through it?

Thanks for the help

You must tell again the excact aio pcb you use.

And again draw on paper (and take picture) to show how you wire. It seems you are overdoing things, because all aio boards have 5v for external, use ( could be 5v was) but an extra 5v is OK also.

It’s an all in 1 PCB with F9P, that’s all I know about it, if TeddyStamford on here is who I think he is then he supplied it before Christmas.

It’s wired just as I described, I know the WAS has 5 amp output but I prefer to solder and heat shrink the connections & I prefer single wires if possible, plus the power reducer was very cheap.

I think I have the WAS finally sorted now too.

So yes, you need to feed 12v+ into pin 18, this is the power source for the motor/valve controller. It’s this power which steers the valve.

We have 2 oc 30l valves that get no pressure at the pressure ssnsor. We installed a gauge but stays zero when turning. Anyone else got this?

This sounds like my issue.

Scroll up to post 755.

Long story short, I think a plug was blocking pressure from cross drilled port. It’s the load sense port for the compensator, and also the same pressure signal the sensor is looking at. It sounds suspiciously like the same issue/symptom.

I ended up grinding off some of the 1/8” hex plug to get oil past the plugs threads. You could try the same, or shimming it first before you start grinding.

You have pictures

EDIT after 1 hour: How is your piping done? in series or parallel?

before or after steering orbital ?

Picture of plug in post 713.

But when you have plug out, you could measure how deep hole is and compare with length of plug.(I used piece of wire bent 90 deg to feel where the hole is) I found depth was Ok on my valve.

I have the feeling that first time after plug is out it does work correct.(maybe because air inside valve block reducing backkick from oil)

But Raycorp, how is your baraki valve positioned?

Because maybe it has influence on how spool inside proportional valve start out. (check before starting tractor, by pressing in the small center knobs (in by about 3 mm at each end of proportional valve)

Then start tractor and check if one of them comes out by itself.

I noticed that one came out resulting in no pressure to steer, but the other knob were still possible to push in by hand (by screwdriver or hex key)

Hello, I would like to equip a second tractor, which is a Fendt 826 SCR with the Baraki Valve… unfortunately i am unable to find the orbitrol? Is it possible that the orbitrol can only be reached by removing the cab? Otherwise, please tell me how i get to it! thanks!