Forum changed servers, pictures from old server are missing.

From the very first post of this thread, there is also a helpful manual included in the google drive file that contains the .stl files. For best results Brim and Support material are required.

Best way to remove support material is needle nose pliers.

A scraper or knife can remove a brim easily. As well as surface blobs

Elephants foot can be trimmed with the side snips that come with a creality printer.

Still updating manual with pictures, and info to help fill in more blanks.

Have you levelled your table in relation to the nozzle?

First rub down the heated bed with alcohol

Take a piece of paper, put it under the nozzle in each corner of the bed. Adjust the bed so the paper slides out with very little effort.

The first layer gets squished into the print bed.

The bed temperature must be tuned, to cold it will not stick, too hot you get excessive drooping also called elephants foot.

If all else fails put painters tape on top of the bed. The plastic really bonds to the surface.

Some people also use hairspray or glue stick to promote adhesion.

I have had a printer under a year, just keep reading about the issues you are having. There is a ton of help online. Once you master the first layer you have 90% of the printer issues figured out. First layer can be tough.

PotatoFarmer, thanks for the informative answer. I haven’t learned enough about the program yet. I understood what an elephant leg is. Read your manual again when printing details. In the settings of the program itself, I set the support for the part, and everything turned out as it should. Thank you very much for your help.

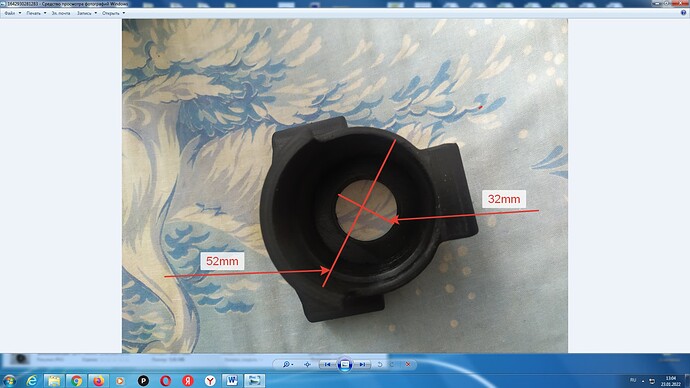

Dear PotatoFarmer. I will have a request for you. On tractor 2, I will have a different electric motor. There, the diameter of the electric motor is smaller. Can you change the file for me to fit my engine. All you have to do is change the diameter. I don’t know how to do it. Let the wall be thicker.

Your printer has made some very nice prints!

Sorry, this design is for the original AOG phidgets 3269_3 motor only, I will only be supporting the use of the one motor on the AOG parts list. Also this project is .stl availability only as described in the manual.

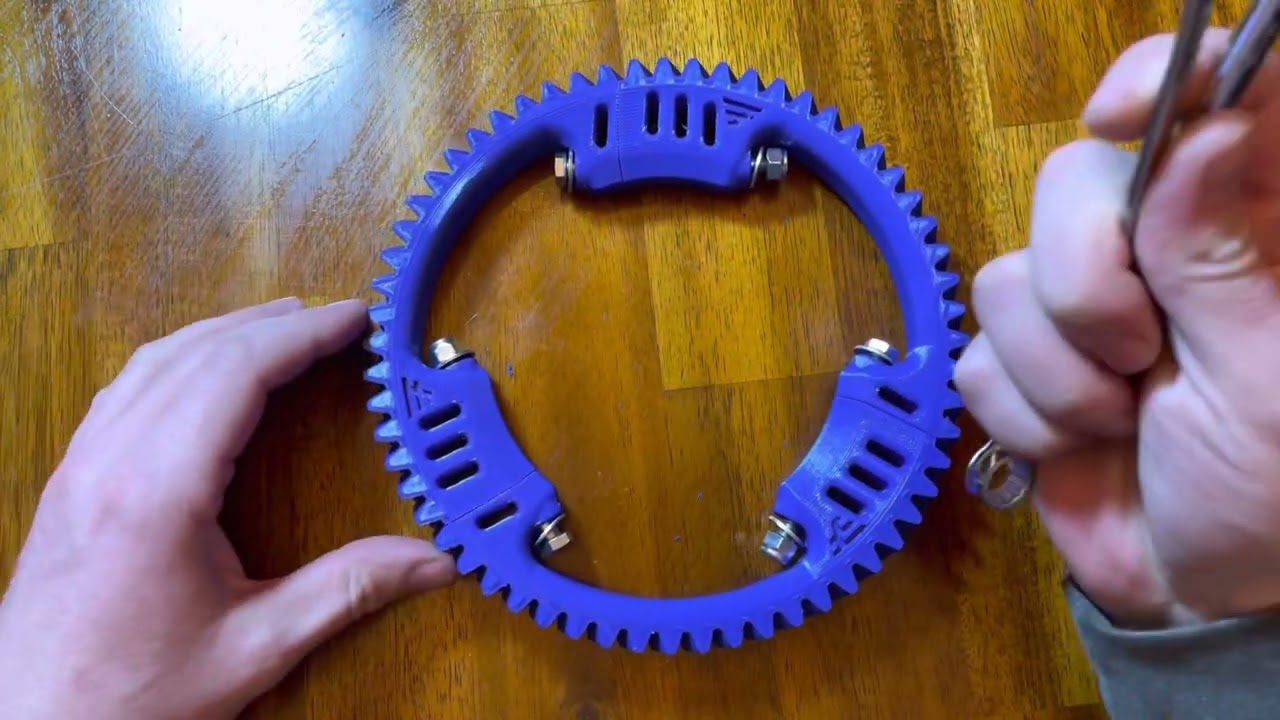

Alterations I am open too, are to make the design within the constraints of the AOG parts list work better or fix existing flaws. For example the requested 3 segment gear, and Metric speed nut.

Understood. I’ll try to create a bushing in the program so that it can be inserted inside, according to the size of my engine.

Just throwing up an idea. Would it be possible to change the shapes where there is fillets or clear round protrusion to chamfers or shapes which are in 45 deg angle? Personally when I’m modelling something for a 3d printer, I try to avoid fillets (the fillets look nice, I know ![]() ). You end up needing less supports and ofter the surface looks better also. The possible issues are normally in the beginning of the fillet or in the end, when even with the supports the printing happens almost in midair. I guess the 45 deg is pretty ok for any printer.

). You end up needing less supports and ofter the surface looks better also. The possible issues are normally in the beginning of the fillet or in the end, when even with the supports the printing happens almost in midair. I guess the 45 deg is pretty ok for any printer.

Support material I just see as part of the 3D process. Also it helps make the parts look like its almost impossible to build with woodworking tools. Support material attaches to the models underside so surface quality is not an issue.

Some of the complexity is I admit is just to make it look really nifty, to show that 3D printing can pull off what normal hand tools cannot. Some of the complexity actually serves a purpose. Some of it is just from trying to cram everything into as tight a space as possible.

My Grandpa built everything out of blocks of wood, so everything he built looked like a block of wood. 3D printing allows you to do almost anything shapely, so why try to recreate Grandpas wood?

Convincing argument. Works for me. ![]()

I have updated the the manual with yet more pictures yesterday. Finally have the parts and hardware ready to make the assembly video this week.

I think i have this printer figured out finally, just have to figure out whats up with the first couple layers on TPU. But the rest has a beautiful finish.

Having issues posting the pic? Must be having site issues? Strange all of a sudden it says its to large off the iphone?

What hardness TPU do you use for the motor gear?

It does not seem to state the hardness on the label, But the TPU is in the link below. When I print the small gear it is very comparable to a hockey puck.

Which 3D printers are people using and what would be an approximate cost in consumables to print a gear set and motor holder

moi ender 3 pro et une bobine te suffit 23€

It will depend on your print settings, but if you printed everything solid (100% infill) with supports, but no rafts then it would use about 720g of PETG and 40g of TPU to print one set, though you could probably get the PETG parts down to under 500g without compromising their strength. These figures are just a quick estimate using PrusaSlicer for a Prusa mk3.

The 750g spools of PETG I normally use cost around £14 when bought during sales. The TPU I normally use is about twice the price per gram, but then a lot less of that is needed.

With the phidget motor can you steer manually with the gears meshed together or do I need to make a linkage to separate the gears when steering manually

If you do the freewheel modification to the cytron gears can be left engaged all the time. It is still nice to be able to disengage them on longer road trips.

Adding a steering feedback sensor like the ACS712 or pressure sensor as well with the cytron modification makes autosteer disengagement very user friendly.